Method for simultaneously separating high-purity phycocyanin and allophycocyanin and application thereof

A technology of allophycocyanin and allophycocyanin, which is applied in the field of simultaneous separation of high-purity phycocyanin and allophycocyanin, can solve the problem of not being able to separate phycocyanin and allophycocyanin at one time, and cannot reach the field of biomedicine Use requirements, product purity is only 2.1, etc., to achieve the effect of facilitating large-scale industrial production, broad prospects for industrialization, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Separation and Purification of Phycocyanin and Allophycocyanin

[0039] (1) Preparation of hydroxyapatite:

[0040] Add 500mL of 0.4M calcium chloride and 0.4M dipotassium hydrogen phosphate dropwise at a rate of 5ml / min to a beaker containing 200ml of 0.4M calcium chloride solution, and keep stirring. After finishing, let the sediment stand, pour off the supernatant, and rinse with enough tap water. Add 2M potassium hydroxide to the precipitate while stirring to ensure that the pH of the precipitate is > 8. After standing for 12 hours, wash it with a large amount of tap water, discard the fine particles, and put it into a piston chromatography column with a size of 1.5cm×20cm. Then balance with 0.001M phosphate buffer solution (pH=6.8) for 3-5 times, wherein the volume ratio of hydroxyapatite precipitate and 1mM phosphate buffer solution (pH=6.8) is about 1:1.

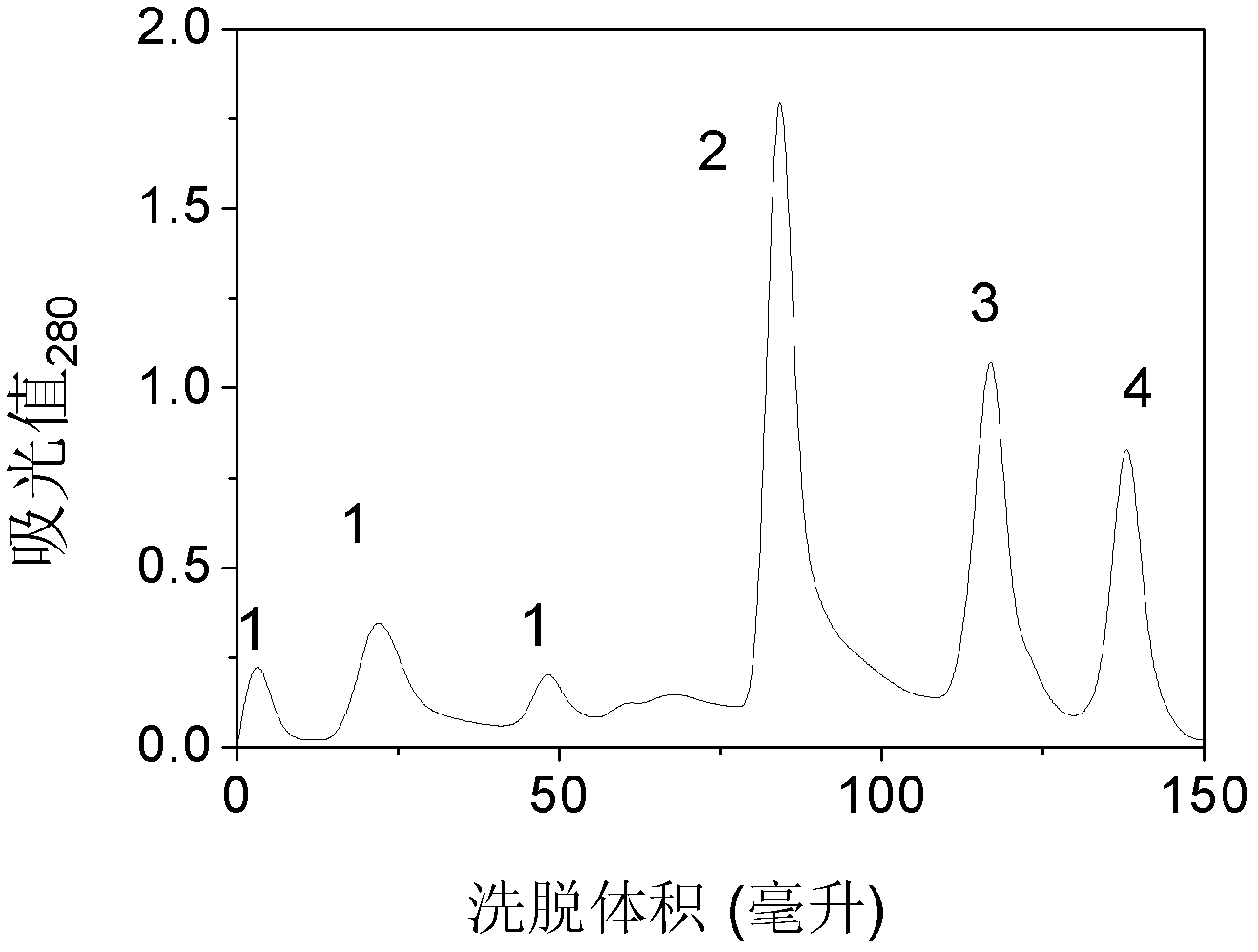

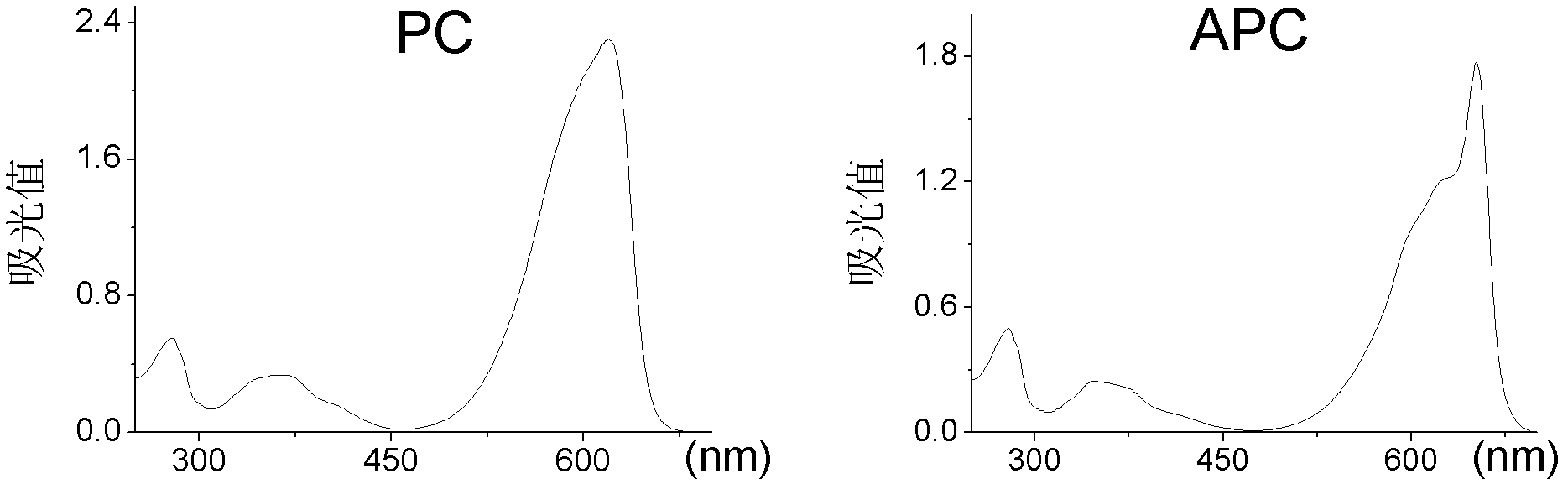

[0041] (2) Separation of phycocyanin and allophycocyanin by hydroxyapatite column chromatography...

Embodiment 2

[0047] Example 2 Separation and purification of selenium-containing phycocyanin and selenium-containing allophycocyanin

[0048] The preparation steps of hydroxyapatite are the same as above. Selenium-containing phycocyanin and selenium-containing allophycocyanin are separated and prepared by the following steps:

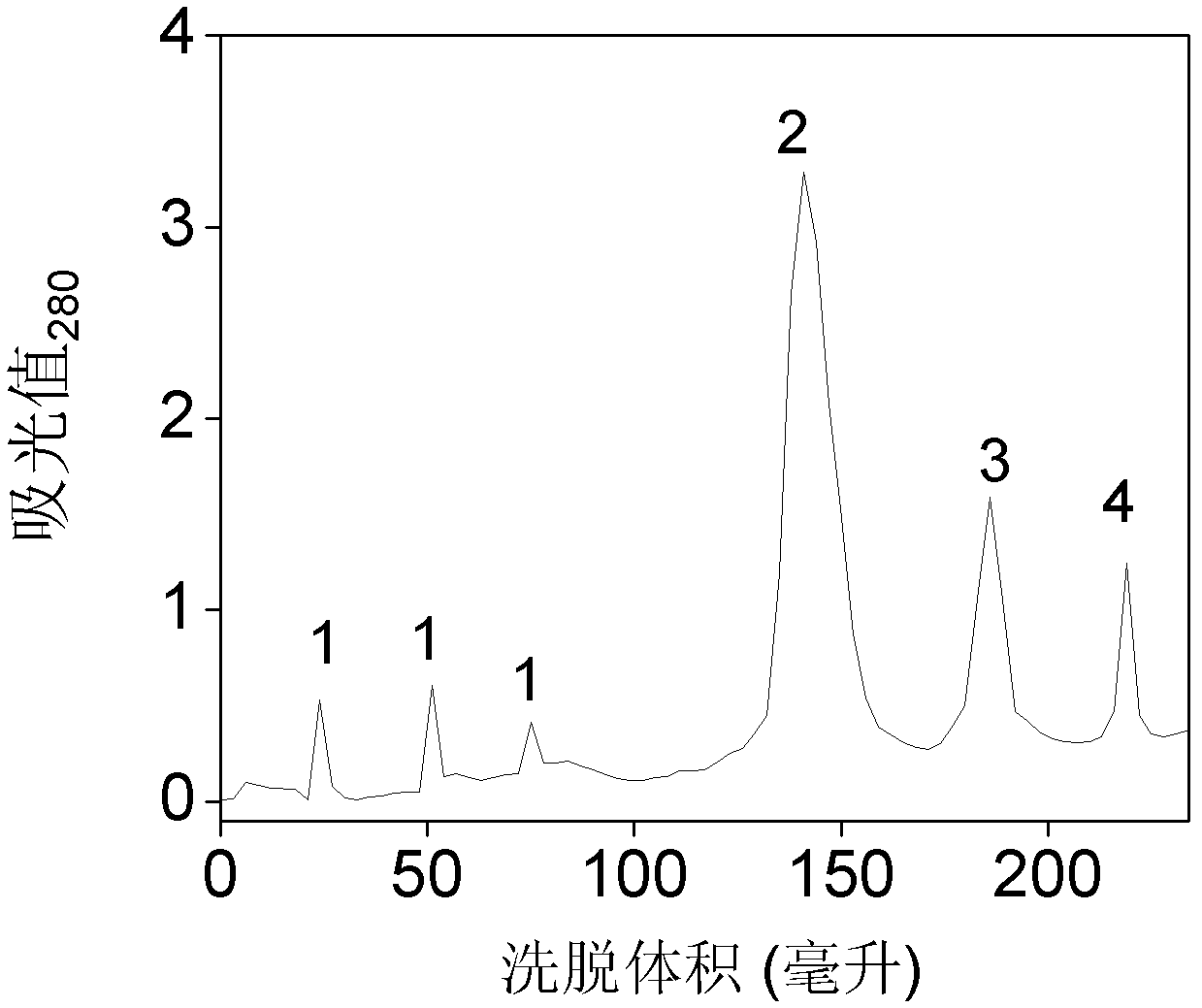

[0049] (1) Preparation of phycobiliprotein crude extract: take commercial sources or self-cultured selenium-enriched Spirulina. The self-cultured selenium-enriched Spirulina culture method is as follows: add Zarrouk culture solution in the Erlenmeyer flask, inoculate Spirulina and adjust the initial A of algae 560 =0.20 (Cultivated in a light incubator, temperature (30±1)°C, pH 8-9, light intensity 72 μmol m -2 ·s -1 ; Add sodium selenite at 7-9 days respectively, and the measured selenium concentration is 100, 150, 200mg·L -1 , starting from the 7th day, the cumulative amount of selenium added every 24 hours was 450mg·L -1 Cultivate until 11d and harvest, filt...

Embodiment 3

[0054] Example 3 Separation and Purification of Tellurium-Containing Phycocyanin and Allophycocyanin

[0055] The preparation steps of hydroxyapatite are the same as above. Separation and preparation of tellurium-containing phycocyanin and allophycocyanin through the following steps:

[0056] (1) Preparation of phycobiliprotein crude extract: take commercially sourced spirulina powder or self-cultured spirulina. The culture method of tellurium-rich Spirulina is as follows: add Zarrouk culture solution to the Erlenmeyer flask, inoculate S. platensis and adjust the initial A 560 =0.20 (Cultivated in a light incubator, temperature (30±2)°C, pH=8~9, light intensity 72μmol·m -2 ·s -1 ; Add sodium tellurite at 7-9 days respectively, and measure the tellurium concentration as 200, 250, 250mg·L -1 , added every 24 hours from the 7th day, the cumulative amount of tellurium added was 700mg·L -1 ; Cultivate until harvested on 11d, filter with 400 mesh gauze. ) in 1mM phosphate buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com