Laver free filament factory cultivation method based on function foodstuff development

A cultivation method and a technology of functional food, which are applied in the field of industrial cultivation of laver free filaments, can solve the problems of being unable to develop food-grade phycobiliproteins, consume a lot of manpower and material resources, and limit the scope of application, and achieve the goal of improving phycobiliproteins. Protein content, convenient source, and the effect of ensuring biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

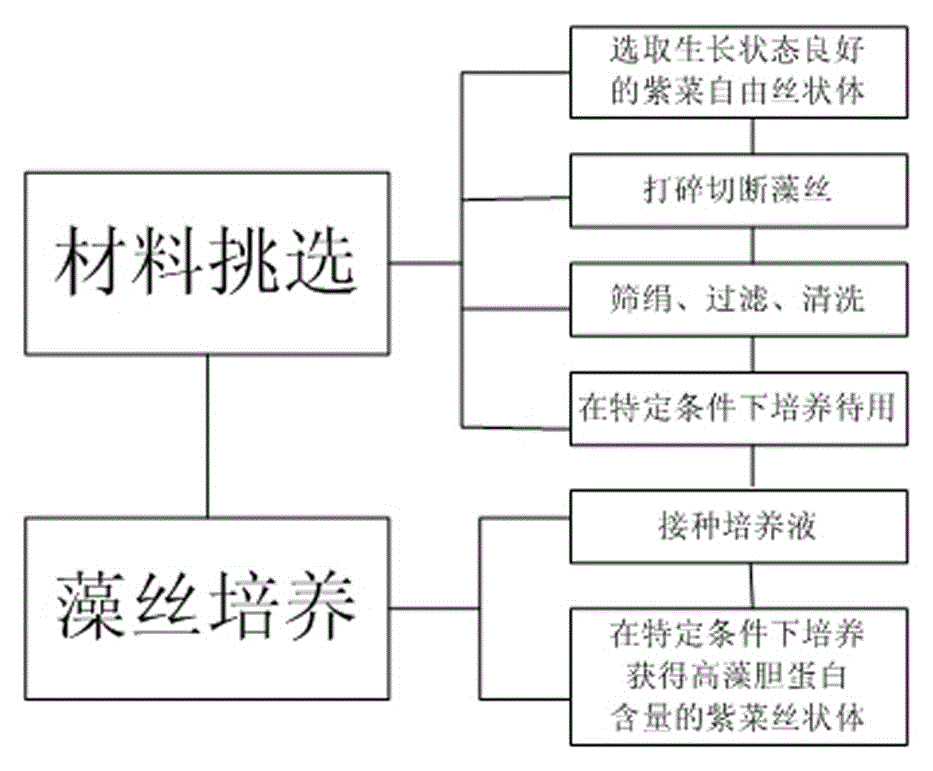

[0037] The present invention is a kind of factory cultivation method of laver free filament developed based on functional food, and the cultivation method process is as follows: figure 1 As shown, this embodiment specifically includes the following steps.

[0038] S1 material selection: the free filamentous strain of algae Porphyra (filamentous algal filaments > 99%) selected by the Algae Breeding Room of the Key Laboratory of Marine Biology, Shantou University. The fronds were collected in Pingyu, Nanao, Shantou in 2012. Completely isolated from the mainland and less polluted. The free filaments were crushed with a pulverizer for 15 seconds, the algal bodies were sieved and washed with sterilized seawater, placed in a 20°C culture room (±1°C) for temporary cultivation, and the light was 40μmol / (m 2 ·s), the light-to-dark ratio is 12h:12h, and the medium 3 / 5 is replaced every seven days. Wait until 15 days for use.

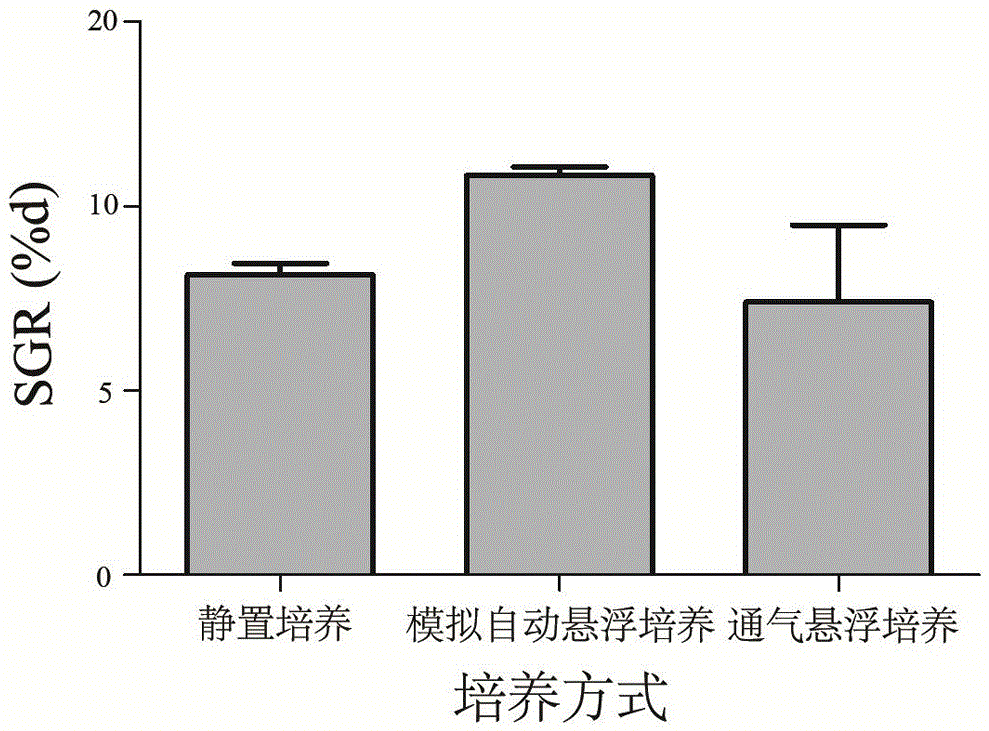

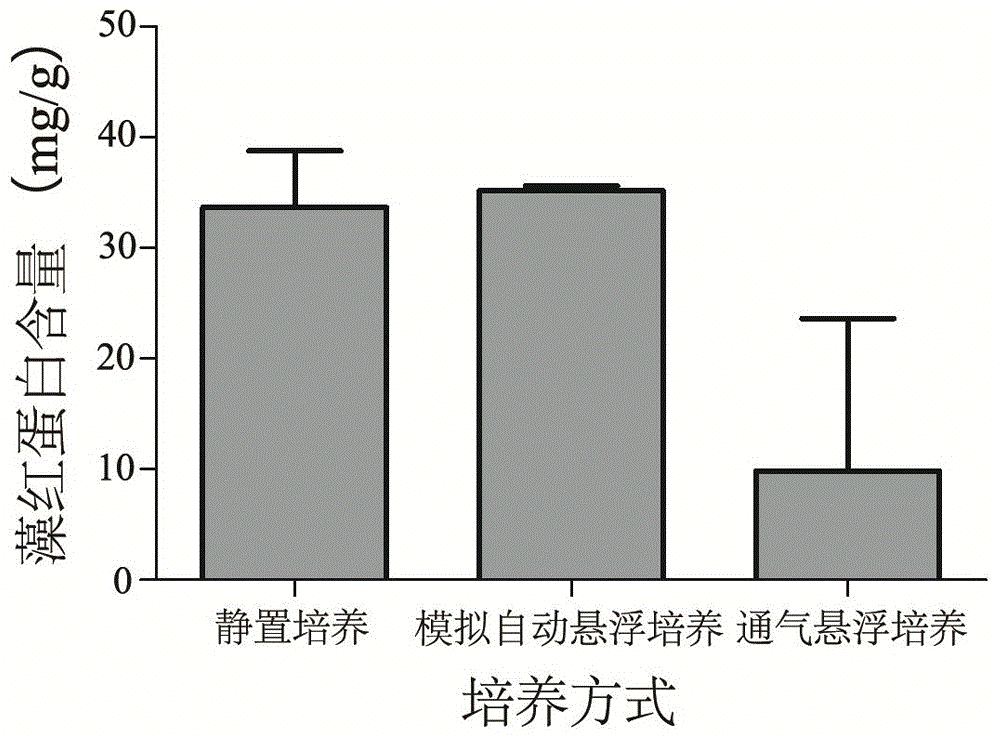

[0039] S2 algae culture: three levels of culture are set ...

Embodiment 2

[0050] S1 material selection: the free filamentous strain of algae Porphyra (filamentous algal filaments > 99%) selected by the Algae Breeding Room of the Key Laboratory of Marine Biology, Shantou University. The fronds were collected in Pingyu, Nanao, Shantou in 2012. Completely isolated from the mainland and less polluted. The free filaments were crushed with a pulverizer for 15 seconds, the algae were filtered with sieved silk, washed with sterilized seawater, placed in a 20°C culture room (±1°C) for temporary cultivation, and the light was 40μmol / (m 2 ·s), the light-to-dark ratio is 12h:12h, and the medium 3 / 5 is replaced every seven days. Wait for up to 14 days for use;

[0051] S2 algal filament culture: Select the above-mentioned filaments with good culture status and inoculate them into conical flasks with an initial density of 1g: 1L culture solution, place them in a 20°C culture room (±1°C) for suspension culture, and set the speed according to the size of the cultu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com