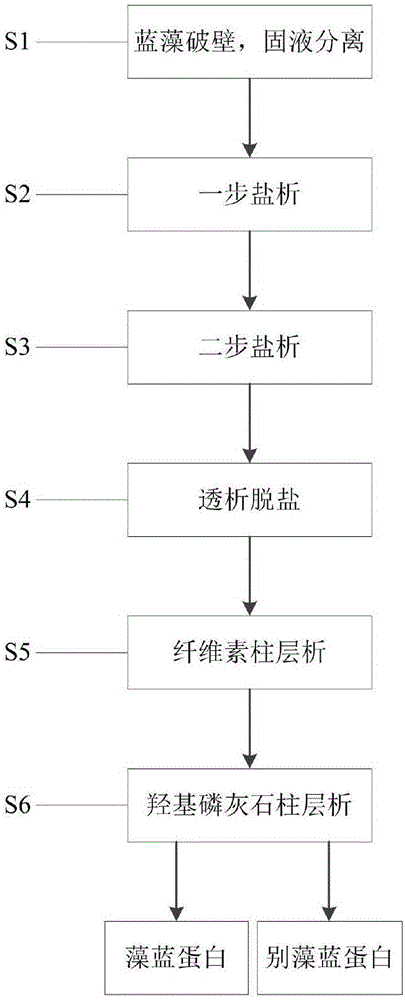

Method for simultaneously separating and purifying reagent-grade phycocyanin and allophycocyanin

A technology of allophycocyanin and phycocyanin, applied in the field of simultaneous separation and purification of reagent-grade phycocyanin and allophycocyanin, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Thaw fresh blue-green algae (water content 99%) stored frozen at -20°C (generally about 10 hours) at 25°C (the thawing time can be selected as about 6h), and then put them under the condition of -20°C Freeze, repeat this step at least 2 times to achieve the broken wall of cyanobacteria cells; coarsely filter the solution after the broken wall of cyanobacteria with multi-layer gauze, the number of gauze is preferably 200 mesh, remove algae residue, and then carry out 8000r / Min high-speed centrifugation, the centrifugation time is 20min, and the phycobiliprotein crude extract can be obtained after removing the residue;

[0040] (2) One-step salting-out: at 4°C, add medium (NH 4 ) 2 SO 4 The solid made the crude extract (NH 4 ) 2 SO 4 The concentration of the solution is 1.0mol / L, stir and mix well, let it stand for 30min, then perform high-speed centrifugation at 8000r / min at 4°C for 20min, discard the precipitate, and keep the supernatant;

[0041] (3) Two-ste...

Embodiment 2

[0050] (1) Thaw fresh blue-green algae (water content 99%) stored at -20°C (generally about 10 hours) at 25°C, and then freeze at -20°C. Repeat this step at least twice to Realize the breaking of cyanobacteria cells; coarsely filter the solution after breaking the walls of cyanobacteria with multi-layer gauze, the number of gauze is preferably 200 mesh, remove the algae residue, and then perform high-speed centrifugation at 8000r / min at 4°C for 20 minutes to remove The phycobiliprotein crude extract can be obtained from the slag;

[0051] (2) One-step salting-out: at 4°C, add medium (NH 4 ) 2 SO 4 The solid made the crude extract (NH 4 ) 2 SO 4 The concentration of the solution is 1.2mol / L, stir and mix well, let it stand for 30min, then perform high-speed centrifugation at 8000r / min at 4°C for 20min, discard the precipitate, and keep the supernatant;

[0052] (3) Two-step salting-out: at 4°C, continue to add (NH 4 ) 2 SO 4 The solid was added to the supernatant (NH ...

Embodiment 3

[0059] (1) Thaw fresh cyanobacteria (water content 99%) stored at -20°C (generally stored for about 10 hours) at 30°C, and then freeze at -20°C. Repeat this step at least twice to Realize the breaking of cyanobacteria cells; coarsely filter the solution after breaking the walls of cyanobacteria with multi-layer gauze, the number of gauze is preferably 200 mesh, remove the algae residue, and then perform high-speed centrifugation at 8000r / min at 4°C for 20 minutes to remove The phycobiliprotein crude extract can be obtained from the slag;

[0060] (2) One-step salting-out: at 4°C, add medium (NH 4 ) 2 SO 4 The solid made the crude extract (NH 4 ) 2 SO 4 The concentration of the solution is 1.4mol / L, stir and mix well, let it stand for 30min, then perform high-speed centrifugation at 8000r / min at 4°C for 20min, discard the precipitate, and keep the supernatant;

[0061] (3) Two-step salting-out: at 4°C, continue to add (NH 4 ) 2 SO 4 The solid was added to the supernata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com