Method for preparing spiral seaweed powder by utilizing microwave vacuum freeze drying

A technology of microwave vacuum and spirulina powder, applied in food preparation, application, food science, etc., can solve the problems of slow water evaporation, large power consumption, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

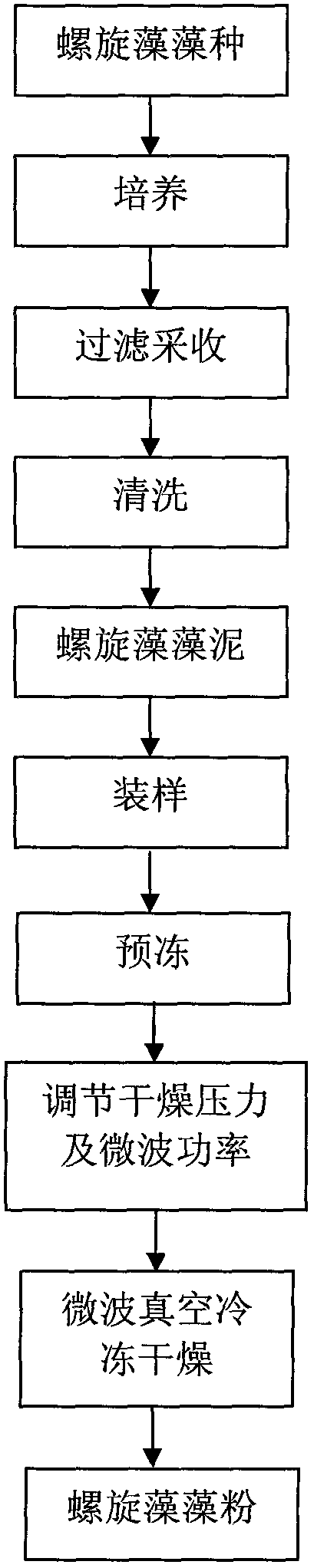

Method used

Image

Examples

Embodiment 1

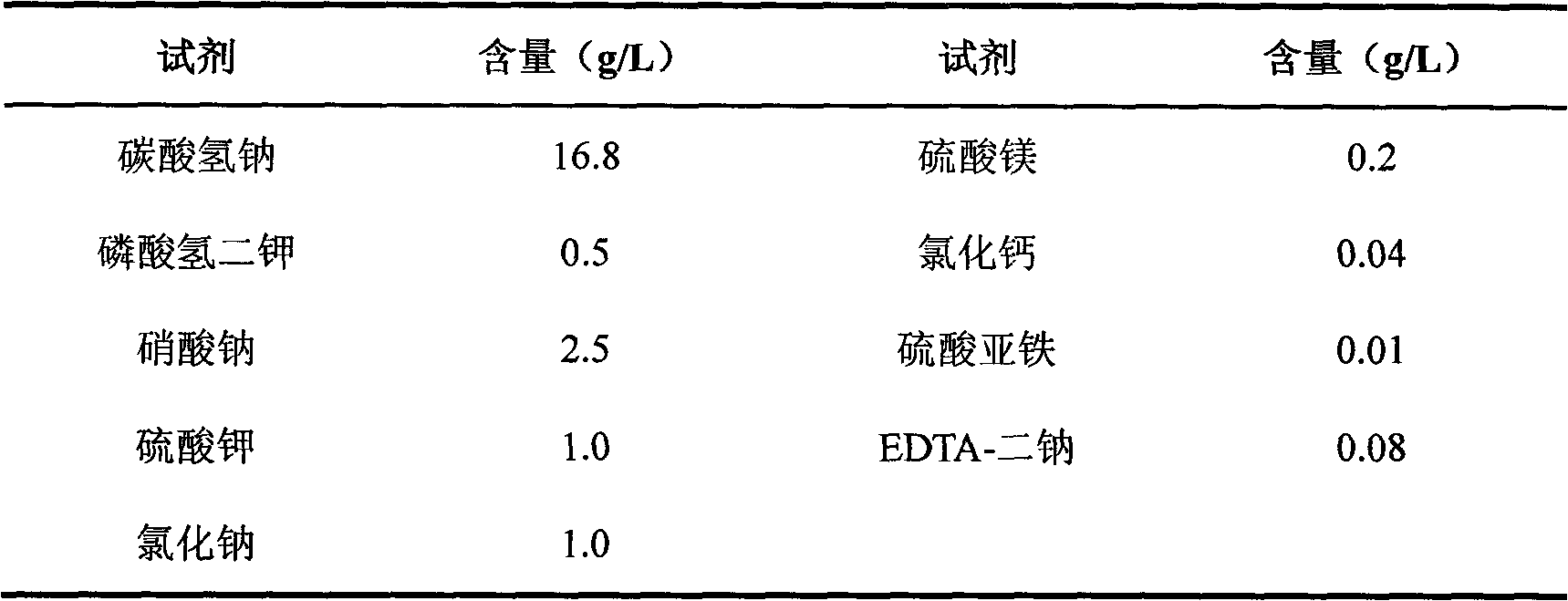

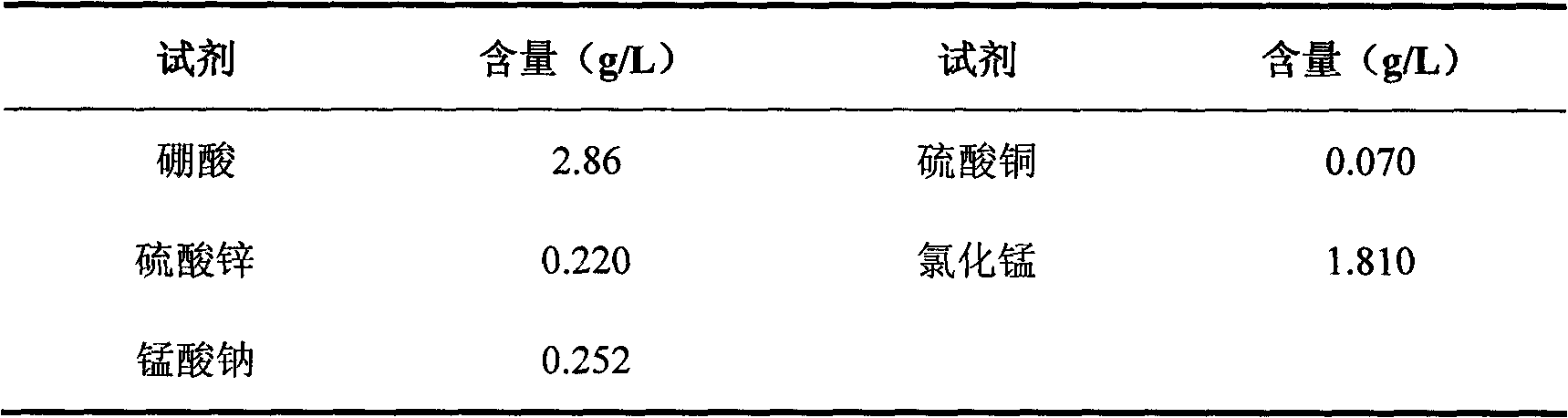

[0015] Prepare 20L of improved Zarrouk medium and put it in a plastic basin. Spirulina was inoculated according to the inoculation amount of 30% (V / V), and continuous culture was adopted, and placed in an artificial climate chamber with automatic temperature and light adjustment functions. The temperature was set at 28°C, and the temperature adjustment range was ±2°C. The strength is 4000Lx, proper stirring and ventilation, the ventilation volume is 120L h -1 . The culture period is 20 days, and the spirulina can be harvested when the concentration of the spirulina liquid increases to an optical density value above 1.0. The spirulina liquid is collected by filtering through a 350-mesh filter cloth, and washed with water repeatedly until the pH value is 7.

[0016] Spread the fresh spirulina on a petri dish with a thickness of 4mm, and place it in the refrigerator for pre-freezing for 10 hours at -25°C. Put the pre-frozen spirulina into the microwave vacuum freeze-drying equi...

Embodiment 2

[0022] Prepare 100 improved Zarrouk medium 20t and place them in a photobioreactor with a volume of 200L, inoculate Spirulina with an inoculum size of 30% (V / V), adopt continuous culture, set the temperature at 28°C, and adjust the temperature The range is ±2°C, the light intensity is 4000Lx, and the air is properly stirred and ventilated, and the ventilation volume is 120L·h -1 . When the cell density of the spirulina cultured in the reactor stabilized, harvesting began. When harvesting, semi-continuous harvesting is carried out according to the gradient of 10% and 20% of the total volume of the culture solution. After harvesting, the same amount of well water and nutrient mother solution are injected to maintain the original volume of the culture solution. The harvested algae fluid is filtered through a 300-mesh sieve to obtain algae mud, and washed with water repeatedly until the pH value is 7.5.

[0023] Spread the fresh spirulina on a freeze-drying tray with a thickness...

Embodiment 3

[0025] Because spray drying and hot air drying consume a lot of energy and can cause a large degree of damage to heat-sensitive substances such as proteins, the present invention compares the effects of four different drying processes on the quality of spirulina: microwave drying, microwave vacuum freeze drying, hot air drying and vacuum freezing. The impact of different drying processes to obtain spirulina algae powder was compared with the algae powder obtained in Example 1, and its dry sensory quality, moisture content, fluidity and other physical parameters and phycobiliprotein content were studied, as shown in Table 3. When measuring the angle of repose, accurately weigh 1g of the spirulina powder sample, fix the funnel with an iron stand, the height of the funnel mouth from the table is 9cm, spread a piece of clean white paper on the table, and the algae powder flows out through the funnel. It will pile up on the white paper below to form a cone shape, measure its bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com