Winged prickly ash-flavored seasoned bamboo shoot slices and preparation method thereof

A technology for seasoning bamboo shoots and vine peppers, applied in the field of bamboo shoot product processing, can solve problems such as the inability to guarantee a single type of bamboo shoots and bamboo shoots, hidden safety hazards, etc., achieve rich taste, reduce the degree of non-enzymatic browning and enzymatic browning, The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

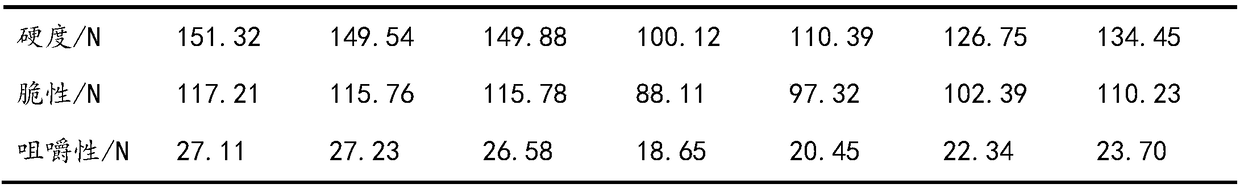

Embodiment 1

[0028] A rattan pepper-flavored seasoned bamboo shoot slice is made of raw and auxiliary materials in the following proportions by weight: 100 parts of bamboo shoot slices; auxiliary materials: 11 parts of bean paste, 2.1 parts of rattan pepper oil, 0.35 part of beef powder, and 0.18 part of yeast powder. 0.18 parts of flavor peptide, 0.35 parts of I+G, 1.4 parts of sodium glutamate, 0.35 parts of white sugar, 0.04 parts of potassium sorbate, 0.04 parts of sodium dehydroacetate, and 0.015 parts of disodium edetate.

[0029] Its preparation method comprises the following steps:

[0030] (1) Raw material pretreatment: select fresh bamboo shoots with complete shape, no pests and diseases, tender meat, and good quality, and clean them. Immediately peel off the bamboo shoots after cleaning, and cut the fresh bamboo shoots into 5cm×2cm×0.5 cm bamboo shoots.

[0031] (2) Submerge the bamboo shoots at 45°C in a solution containing 0.15% calcium chloride, place them in a microwave dry...

Embodiment 2

[0036] A rattan pepper-flavored seasoned bamboo shoot slice is made of raw and auxiliary materials in the following proportions by weight: 100 parts of bamboo shoot slices; auxiliary materials: 12 parts of bean paste, 2.3 parts of rattan pepper oil, 0.3 part of beef powder, and 0.15 part of yeast powder. 0.15 parts of flavor peptide, 0.3 parts of I+G, 1 part of sodium glutamate, 0.3 parts of white sugar, 0.03 parts of potassium sorbate, 0.03 parts of sodium dehydroacetate, and 0.01 parts of disodium edetate.

[0037] Its preparation method comprises the following steps:

[0038] (1) Raw material pretreatment: select fresh bamboo shoots with complete shape, no pests and diseases, tender meat, and good quality, and clean them. Immediately peel off the bamboo shoots after cleaning, and cut the fresh bamboo shoots into 5cm×2cm×0.5 cm bamboo shoots.

[0039] (2) Submerge the bamboo shoots at 40°C in a solution containing 0.1% calcium chloride, place them in a microwave drier, and ...

Embodiment 3

[0044] A rattan pepper-flavored seasoned bamboo shoot slice is made of raw and auxiliary materials in the following proportions by weight: 100 parts of bamboo shoot slices; auxiliary materials: 13 parts of bean paste, 2.5 parts of rattan pepper oil, 0.4 part of beef powder, and 0.2 part of yeast powder. 0.2 parts of flavor peptide, 0.4 parts of I+G, 1.5 parts of sodium glutamate, 0.4 parts of white sugar, 0.05 parts of potassium sorbate, 0.05 parts of sodium dehydroacetate, and 0.02 parts of disodium edetate.

[0045] Its preparation method comprises the following steps:

[0046] (1) Raw material pretreatment: select fresh bamboo shoots with complete shape, no pests and diseases, tender meat, and good quality, and clean them. Immediately peel off the bamboo shoots after cleaning, and cut the fresh bamboo shoots into 5cm×2cm×0.5 cm bamboo shoots.

[0047] (2) Submerge the bamboo shoots at 50°C in a solution containing 0.2% calcium chloride, place them in a microwave drier and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com