Method of extracting bio-active substances from algae

A technology of bioactive substances and algae, which is applied in the preparation method of peptides, chemical instruments and methods, organic chemistry, etc., can solve the problems of limited output, single extraction of bioactive ingredients, and scarce distribution of Gexianmi, so as to save raw materials, High yield and purity, guaranteed yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

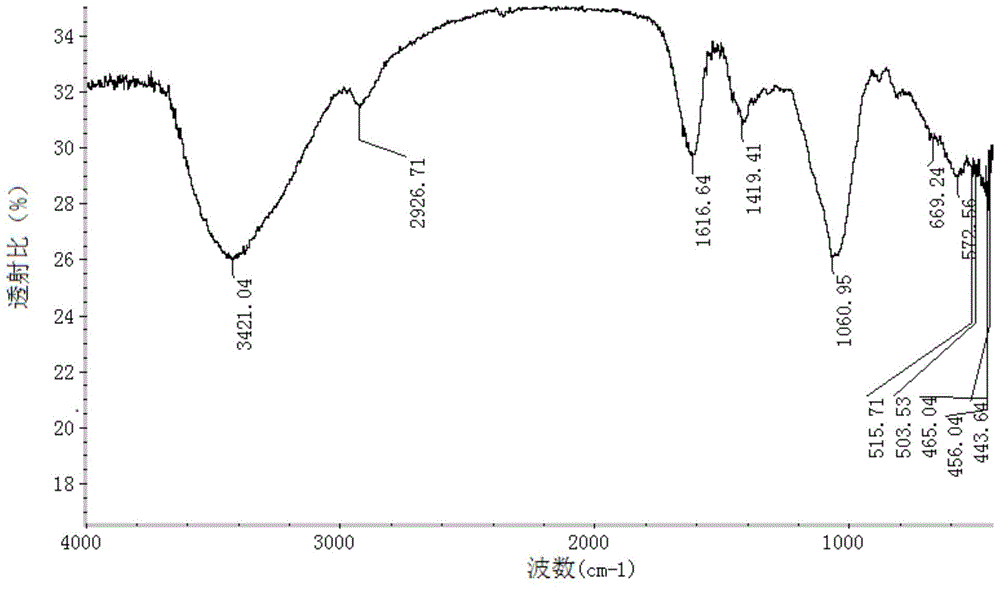

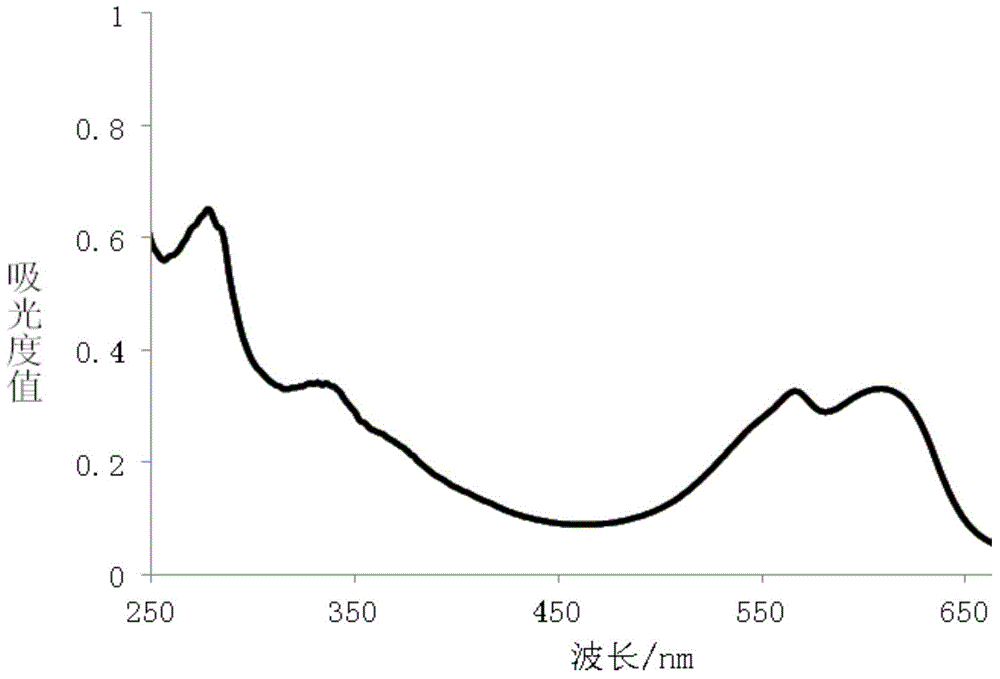

Image

Examples

Embodiment 1

[0062] (1) Extraction by breaking the wall: Weigh 20g of Ge Xianmi sample, swell with 200mL of pH 7.3 phosphate buffer (0.02mol / L) at 4°C, freeze at -20°C for 8h, and thaw at 25°C, repeat the process for 3 The second time, add 400mL of extraction buffer, place in a high-speed tissue homogenizer for high-speed tissue homogenization (5000rpm, 4°C for 4h), centrifuge at 10000r / min for 20min at 4°C, and take the supernatant.

[0063] (2) Salting out: add ammonium sulfate to the supernatant (so that the concentration of ammonium sulfate in the system is 20% by weight), precipitate at 4°C for 8h, centrifuge at 10000r / min for 20min at 4°C, take the supernatant, discard After precipitation, the supernatant was continued to be precipitated with ammonium sulfate (the concentration of ammonium sulfate in the control system was 30% by weight) (4°C, 8h), centrifuged at 10000r / min for 20min at 4°C, and the supernatant was taken by centrifugation and the precipitate was collected. In this wa...

Embodiment 2

[0067] (1) Extraction by breaking the wall: Weigh 20 g of Ge Xianmi sample, swell with 80 mL of pH 5 phosphate buffer (0.02mol / L) at 15°C, freeze at -20°C for 8 hours, and thaw at 25°C, and repeat the treatment 3 times. Add 400mL of extraction buffer, place in a high-speed tissue homogenizer for high-speed tissue homogenization (5000rpm, 15°C for 4h), centrifuge at 10000r / min for 20min at 4°C, and take the supernatant.

[0068] (2) Salting out: add ammonium sulfate to the supernatant (so that the concentration of ammonium sulfate in the system is 15% by weight), precipitate at 4°C for 8h, centrifuge at 10000r / min for 20min at 4°C, take the supernatant, discard After precipitation, the supernatant was continued to be precipitated (4°C, 8h) with ammonium sulfate (the concentration of ammonium sulfate in the control system was 35% by weight), centrifuged at 10000r / min for 20min at 4°C, and the supernatant was taken by centrifugation and the precipitate was collected. In this way,...

Embodiment 3

[0072] (1) Extraction by breaking the wall: Weigh 20g of Ge Xianmi sample, swell with 300mL of pH 8.5 phosphate buffer solution (0.02mol / L) at 10°C, freeze at -20°C for 8h, and thaw at 25°C, repeat the process for 3 The second time, add 400mL of extraction buffer, place in a high-speed tissue homogenizer for high-speed tissue homogenization (5000rpm, 10°C for 4h), centrifuge at 10000r / min for 20min at 4°C, and take the supernatant.

[0073] (2) Salting out: add ammonium sulfate to the supernatant (so that the concentration of ammonium sulfate in the system is 25% by weight), precipitate at 4°C for 8h, centrifuge at 10000r / min for 20min at 4°C, take the supernatant, discard After precipitation, the supernatant was continued to be precipitated (4°C, 8h) with ammonium sulfate (the concentration of ammonium sulfate in the control system was 50% by weight), centrifuged at 10000r / min for 20min at 4°C, and the supernatant was obtained by centrifugation and the precipitate was collecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com