Aluminum product bending system and process

A technology for bending and forming aluminum products, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of poor aesthetics of aluminum products, cumbersome process steps, etc., and achieve simple bending steps, convenient operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

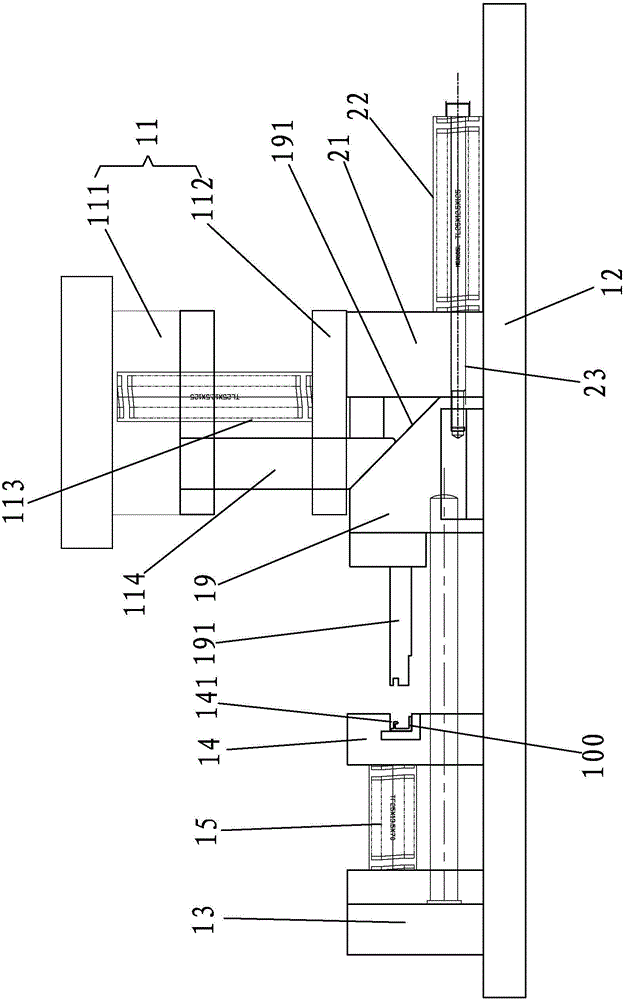

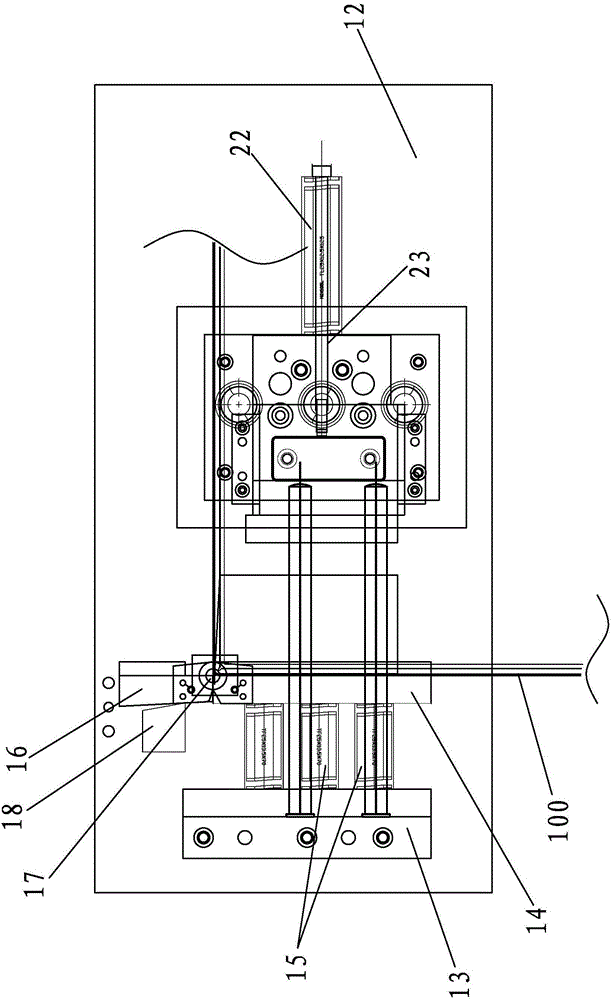

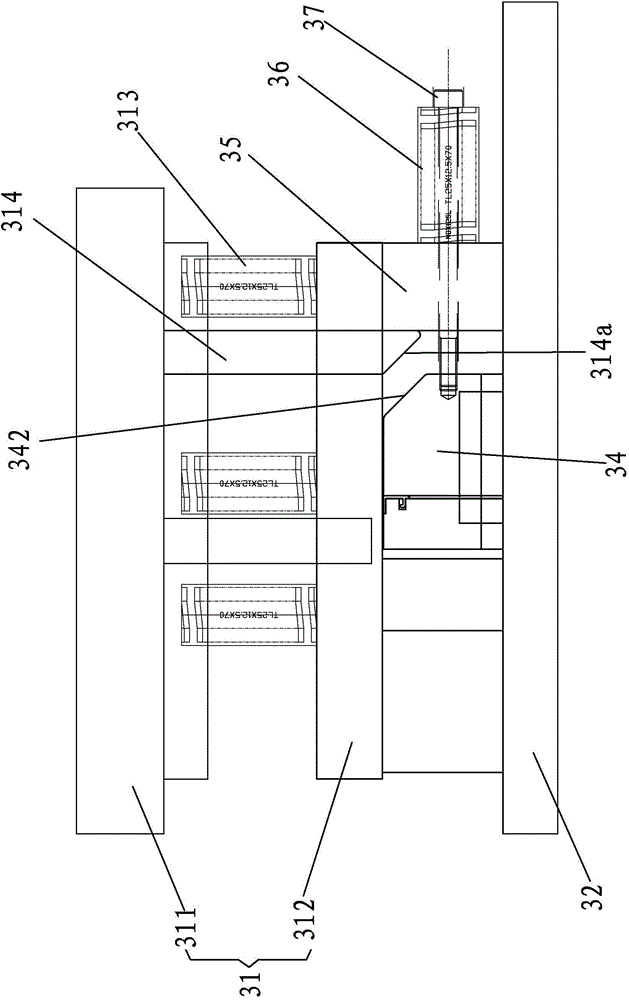

[0030] A kind of aluminum product bending forming system of the present invention, such as Figure 1-6 As shown, it includes a bending device for bending a strip-shaped aluminum product 100, a shaping device for punching and shaping the bent aluminum product, and a trimming device for cutting off the remaining edge of the shaped aluminum product; wherein:

[0031]The bending device includes a first upper mold base 11 and a first lower mold base 12, and the upper surface of the first lower mold base 12 is fixed with a fixed base 13 and the right side of the fixed base 13, and can move left and right. Seat 14, between fixed seat 13 and movable seat 14, be provided with the first reset device that controls movable seat 14 to reset to the right, and this first reset device is tension spring 15, and tension spring 15 is horizontal setting in left and right direction, and The left end of the tension spring 15 is fixedly connected to the fixed seat 13, and the right end of the tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com