Molding device and molding method of saddle-shaped coil

A molding device, saddle-shaped technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of easy damage to the copper wire insulation layer, difficult to ensure the size of the coil, and the decline in the quality of the coil, so as to achieve a compact structure and ensure Stable, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

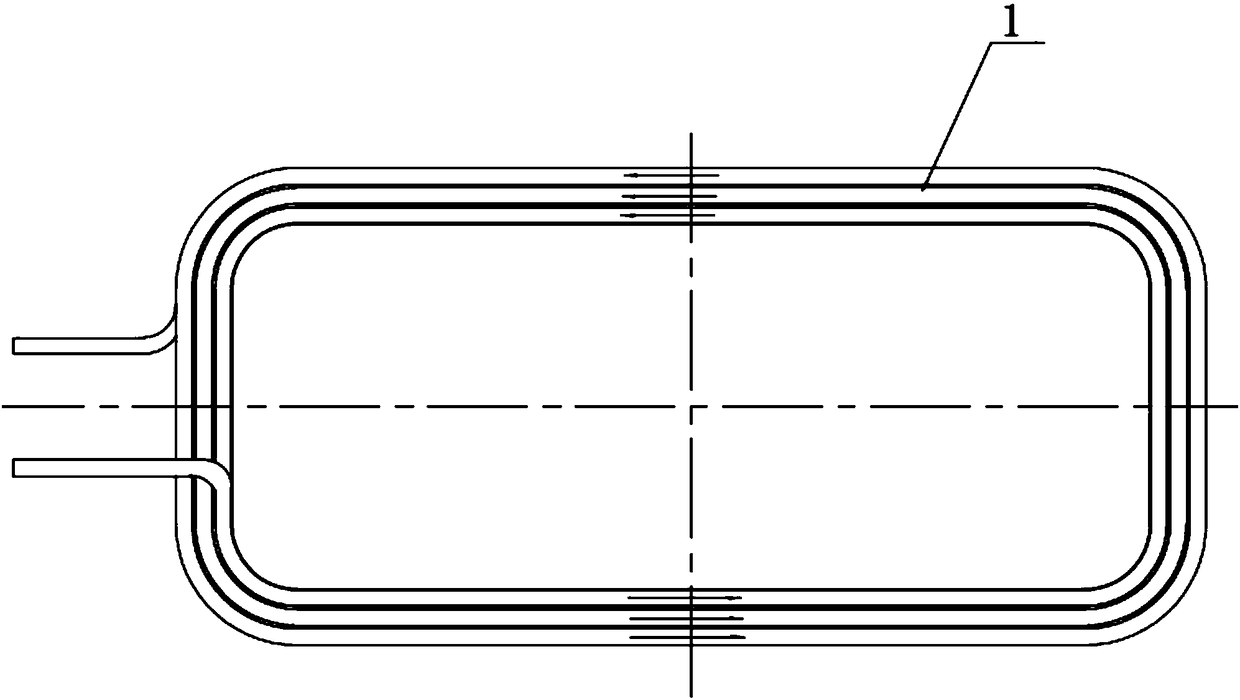

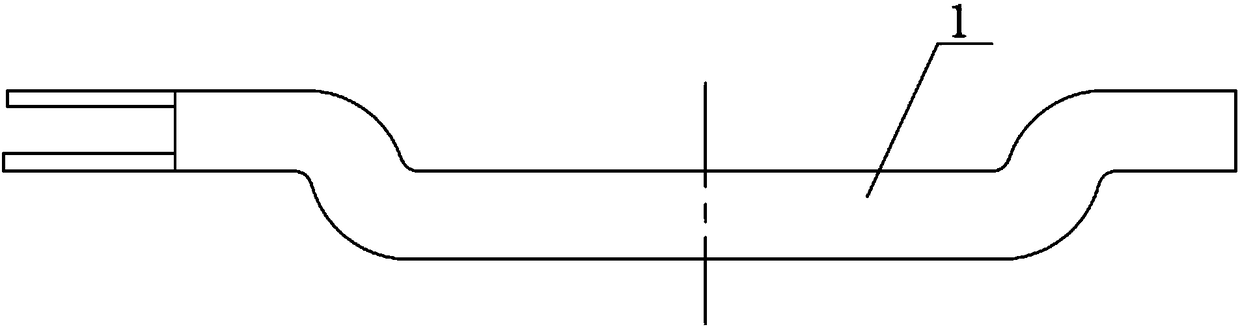

[0056] Such as Figure 1-Figure 12 As shown, the saddle-shaped coil forming device of this embodiment includes a winding tool installed on the winding machine, on which the coil is wound, and also includes a primary bending device and a secondary bending device for positioning and fixing the coil device.

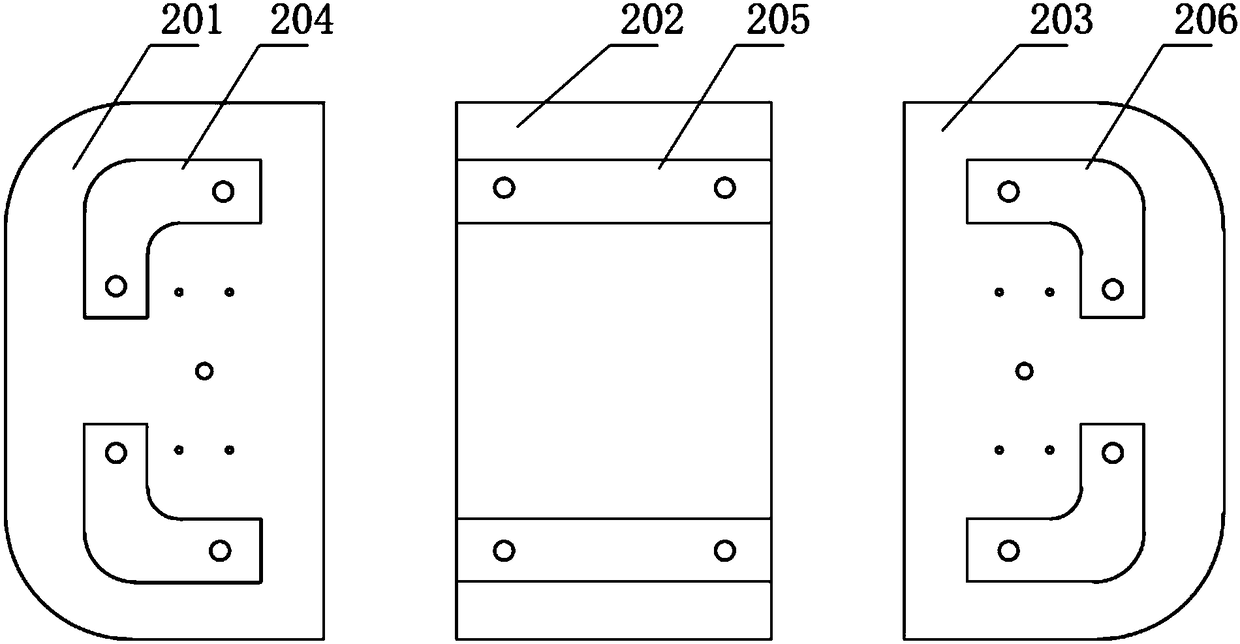

[0057] The winding tooling is a rectangular structure, and the interval is divided into a left half tooling part 201, a middle tooling part 202 and a right half tooling part 203. The left half tooling part 201 and the right half tooling part 203 are respectively provided with a left half bending raised structure 204 and a The right half-bending protruding structure 206 , the left half-bending protruding structure 204 and the right half-bending protruding structure 206 are arranged oppositely, and the middle tooling part 202 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com