Automatic molding machine for cross girder type steel bar

An automatic forming machine and traveling beam technology, which is applied in the field of steel bar bending machines, can solve the problems of high labor intensity, increase of worker's operation steps, and low work efficiency, so as to reduce labor intensity, save operation procedures, improve work efficiency and The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

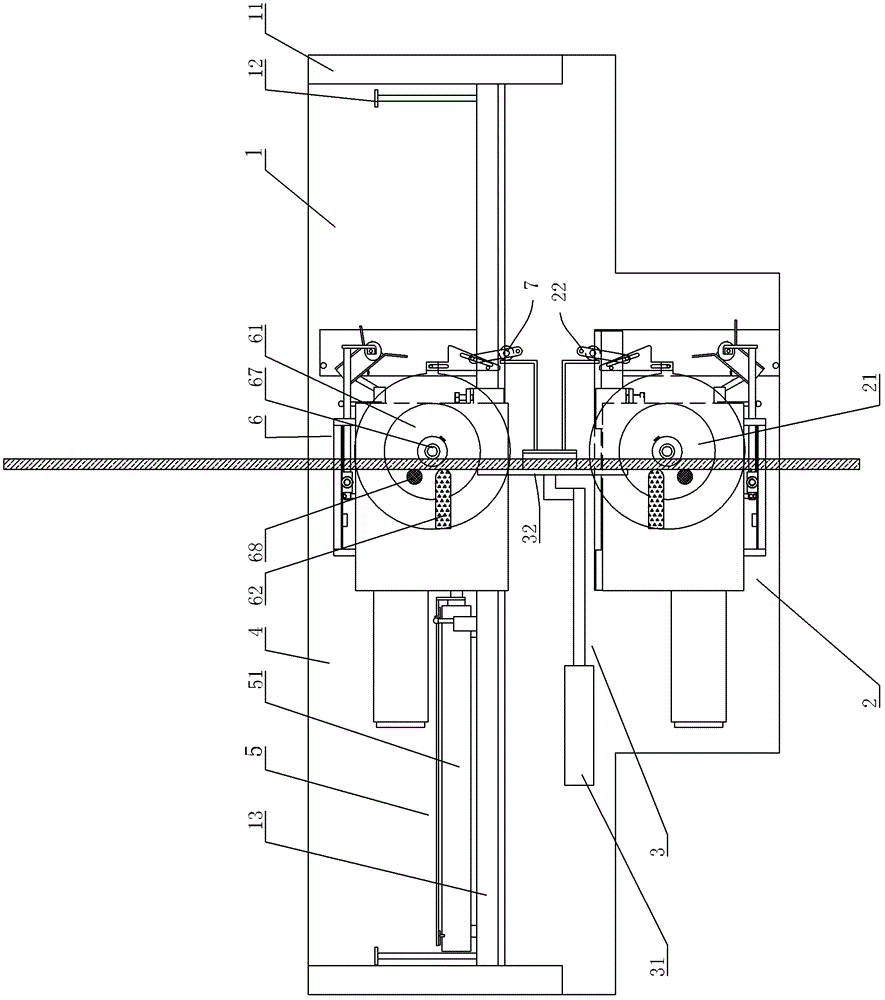

[0034] Such as figure 1 As shown, a running beam type steel bar automatic forming machine includes a frame 1, and guide rails 11 are arranged on both sides of the frame 1, and guide rail beams 13 are fixed between the guide rails 11 through adjusting screw rods 12, and the adjusting screw rods can be adjusted by tightening and loosening 12 to make the guide rail beam 13 move between the two guide rails, thereby adjusting the position of the guide rail beam 13 to adapt to the bending requirements of steel bars of different specifications and models.

[0035] The frame 1 is provided with a fixed bending mechanism 2, a steel bar driving mechanism 3 and a movable bending mechanism 4 from front to back.

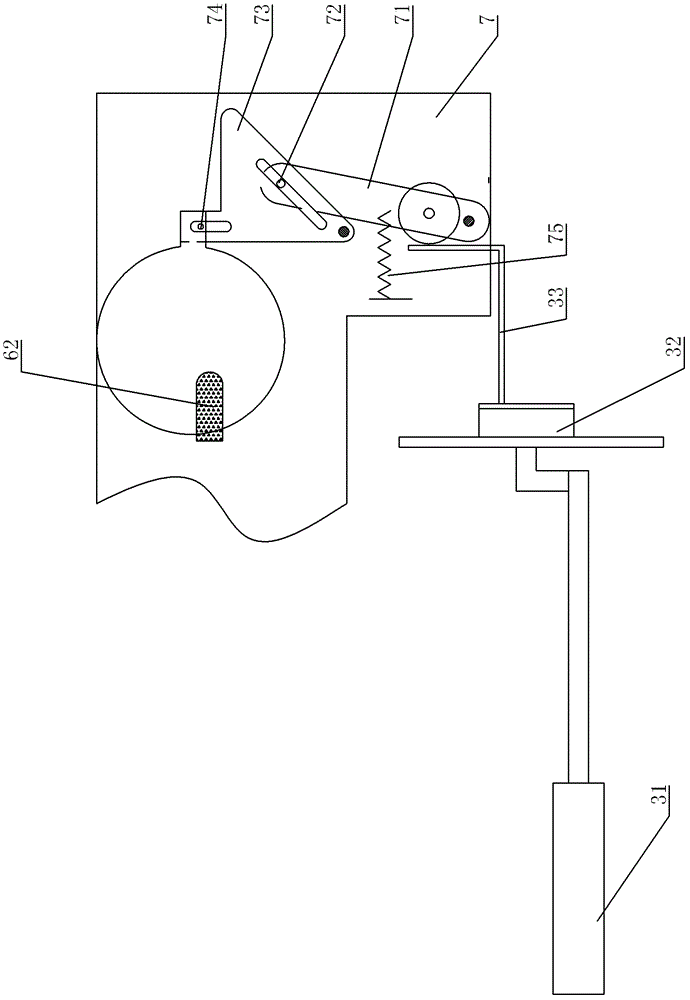

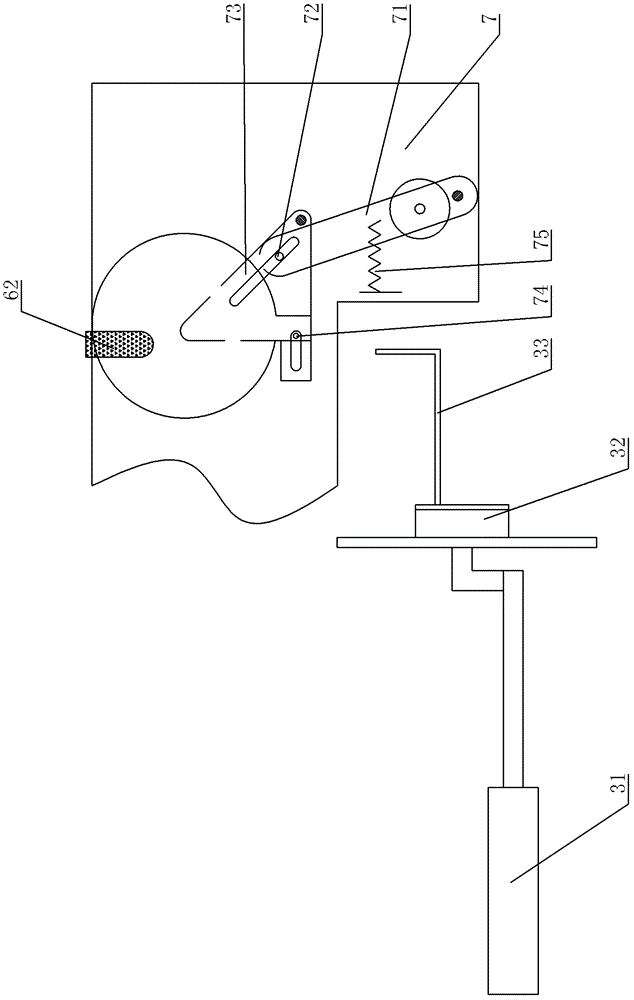

[0036] Such as figure 1 , Figure 4 and Figure 5 As shown, the mobile bending mechanism 4 is composed of two parts, which are a driving device 5 and a bending device 6 respectively. The driving device 5 includes a first oil cylinder 51 fixed on the guide rail beam 13 , a trav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com