Modular bending equipment for profile machining and bending method of modular bending equipment

A modular and profile technology, applied in the field of profile processing, can solve the problems of inability to guarantee the quality and precision of profile forming, low production efficiency, increase labor force, etc., and achieve the effect of improving versatility and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

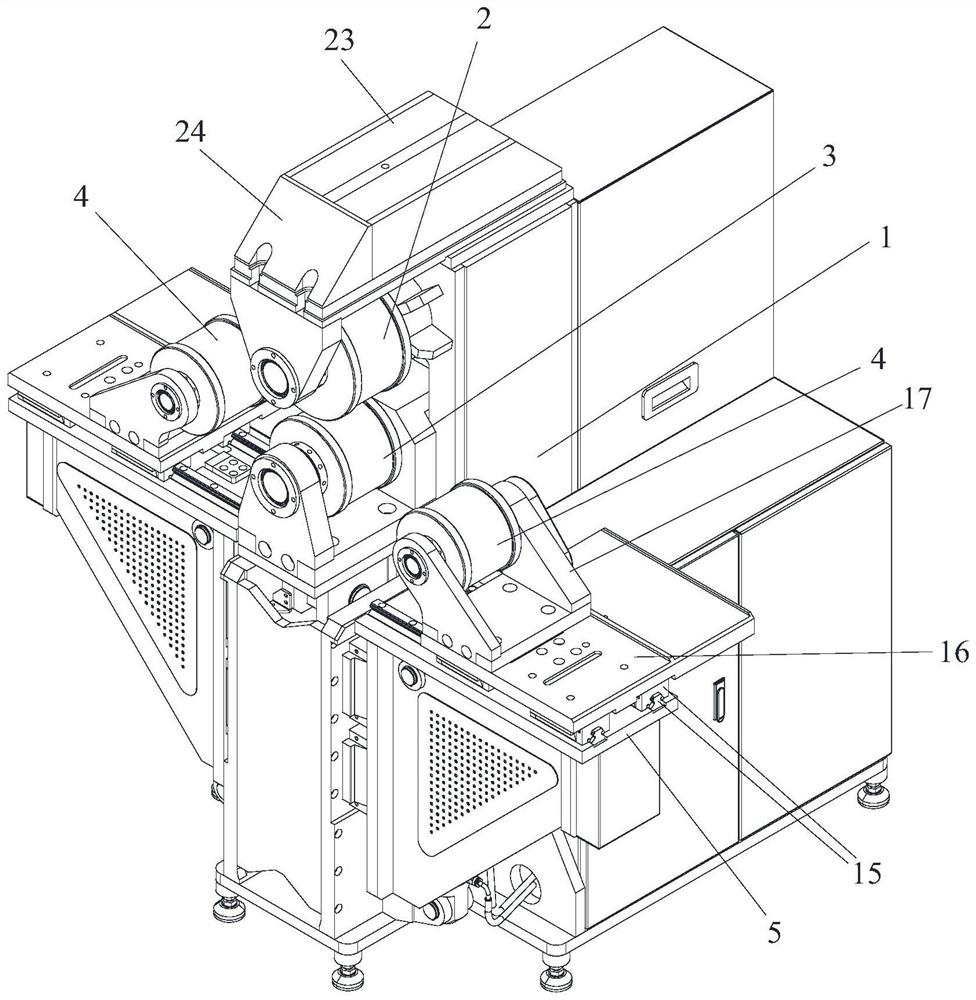

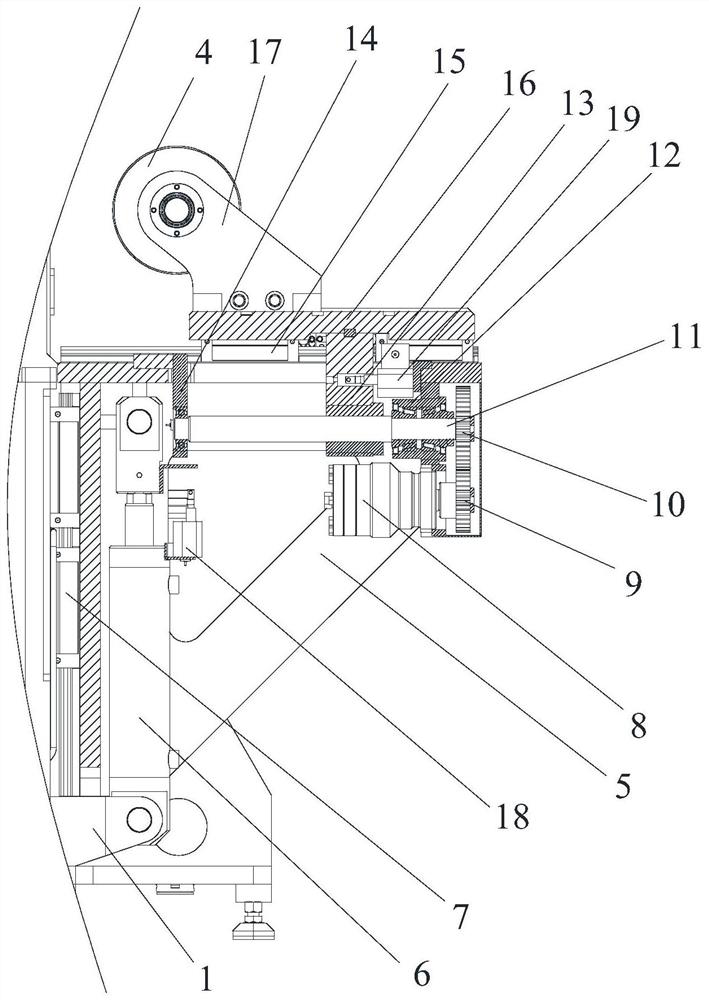

[0040] In this embodiment, two side roller mechanisms are provided as an example to describe the following.

[0041] Such as Figure 1 to Figure 4 As shown, the modular bending equipment for profile processing of the present invention includes a frame 1, two side roller mechanisms, an upper spindle roller mechanism and a lower spindle roller mechanism, wherein the upper spindle roller mechanism is provided with an upper spindle roller 2, and the lower spindle roller mechanism The lower main shaft roll 3 is provided, and the upper main shaft roll mechanism is arranged on the frame 1 and the upper main shaft roll 2 is a driving roll, the lower main shaft roll mechanism is arranged on the frame 1, and the lower main shaft roll 3 is positioned at the upper main shaft roll 2 below and can Lifting, the lower main shaft roller 2 is also a driving roller. The two side roller mechanisms are respectively arranged on both sides of the upper spindle roller mechanism, and are detachably c...

Embodiment 2

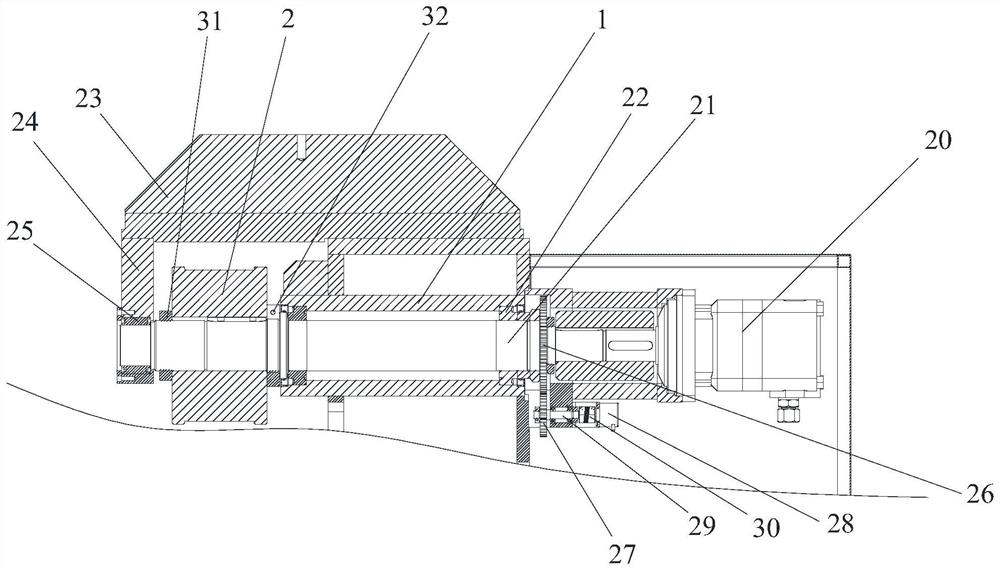

[0055] This embodiment differs from Embodiment 1 only in that: Figure 5 As shown, the upper main shaft roller 2 of this embodiment is set to a special shape, and the upper main shaft roller 2 adopts a special-shaped structure to meet the bending processing of various curvatures. When turning to the desired radius, it stops, and the profile is bent through the side rollers, and the turning of the upper spindle roller 2 can be continuously adjusted to perform bending with different curvatures.

[0056] Other structures of this embodiment are consistent with Embodiment 1.

Embodiment 3

[0058] This embodiment differs from Embodiment 1 only in that: Figure 6 As shown, the modularized bending equipment in this embodiment also includes a feeding mechanism 42 for conveying the profile, and the feeding mechanism 42 is arranged at the side of the frame 1 to realize conveying the profile to the profile bending station. The feeding mechanism 42 of the present invention automatically transfers the profile to the profile bending station for automatic processing of the profile bending. The feeding mechanism 42 can adopt mature mechanical equipment commonly used in profile bending processing on the market, such as a feeding trolley.

[0059] Other structures of this embodiment are consistent with Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com