Aluminum alloy surface treatment method and aluminum product

A surface treatment, aluminum alloy technology, applied in the field of aluminum products, can solve the problems of low silicon content, inability to effectively improve the uniformity of aluminum alloy coloring, uneven distribution of silicon, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

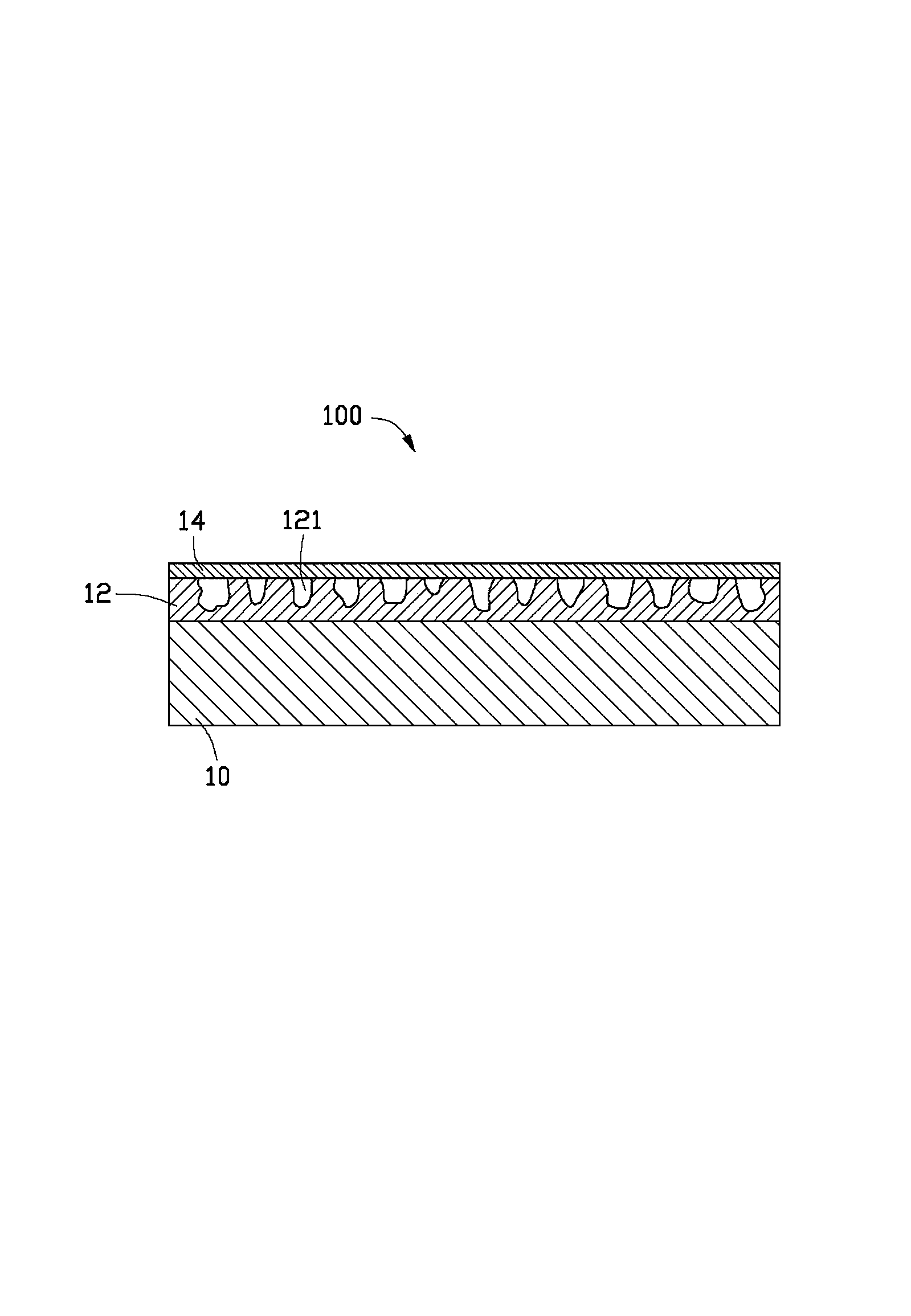

Image

Examples

Embodiment 1

[0040] (1) Ultrasonic cleaning: the aluminum alloy substrate 10 is ultrasonically cleaned with absolute ethanol for about 30 minutes.

[0041] (2) Air-drying treatment: using a blower, adjusting the angle of the blower to 30°, and air-drying the aluminum alloy substrate 10 after the ultrasonic cleaning treatment. The air drying was carried out at room temperature for 2 minutes.

[0042] (3) Solution treatment: the aluminum alloy substrate 10 was placed in a box-type resistance furnace at a temperature of 525° C. for 8 hours.

[0043](4) Quenching treatment: within 5 seconds after taking out the aluminum alloy substrate 10 , put it into water at a temperature of 20° C. for quenching treatment. The time of the quenching treatment is 5 minutes.

[0044] (5) Pickling treatment: Prepare pickling solution, wherein the volume percentage of nitric acid and hydrofluoric acid in the pickling solution is 8:1. The quenched aluminum alloy substrate 10 is immersed in the pickling solutio...

Embodiment 2

[0051] (1) Ultrasonic cleaning: Ultrasonic cleaning is performed on the aluminum alloy substrate with absolute ethanol for about 30 minutes.

[0052] (2) Air-drying treatment: using a blower, adjusting the angle of the blower to 50°, and air-drying the aluminum alloy substrate after ultrasonic cleaning. The air drying was carried out at room temperature for 2 minutes.

[0053] (3) Solution treatment: the aluminum alloy substrate was placed in a box-type resistance furnace at a temperature of 510° C. for 9 hours.

[0054] (4) Quenching treatment: within 5 seconds after taking out the aluminum alloy base material, place it in water at 15° C. for quenching treatment. The time of the quenching treatment is 5 minutes.

[0055] (5) Pickling treatment: Prepare pickling solution, wherein the volume percentage of nitric acid and hydrofluoric acid in the pickling solution is 10:1.5. The quenched aluminum alloy substrate is immersed in the pickling solution for 5 minutes. The picklin...

Embodiment 3

[0062] (1) Ultrasonic cleaning: Ultrasonic cleaning is performed on the aluminum alloy substrate with absolute ethanol for about 30 minutes.

[0063] (2) Air-drying treatment: using a blower, adjusting the angle of the blower to 60°, and air-drying the aluminum alloy substrate after ultrasonic cleaning. The air drying was carried out at room temperature for 3 minutes.

[0064] (3) Solution treatment: the aluminum alloy substrate was placed in a box-type resistance furnace at a temperature of 495° C. for 10 hours.

[0065] (4) Quenching treatment: within 5 seconds after taking out the aluminum alloy base material, put it into water at 20° C. for quenching treatment. The time of the quenching treatment is 5 minutes.

[0066] (5) Pickling treatment: Prepare pickling solution, wherein the volume percentage of nitric acid and hydrofluoric acid in the pickling solution is 9:1. The quenched aluminum alloy substrate is immersed in the pickling solution for 10 minutes. The pickling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com