Aluminum alloy for casting-forge, and aluminum casting forged product and manufacturing method therefor

a technology of aluminum alloy and casting forge, which is applied in the direction of steering linkages, transportation and packaging, mechanical equipment, etc., can solve the problems of increasing cost, reducing the weight of automobiles, and increasing the cost of materials for reducing weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

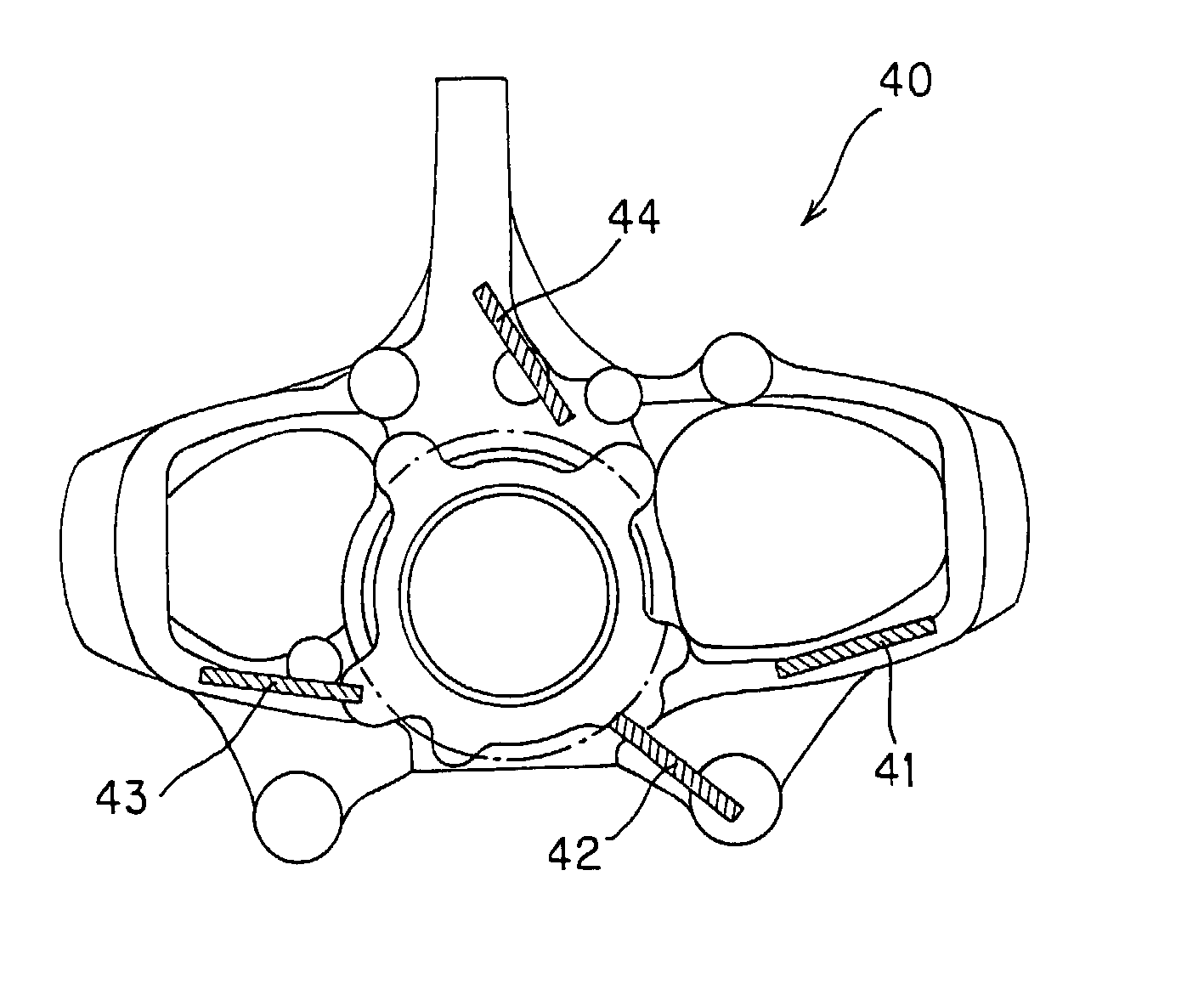

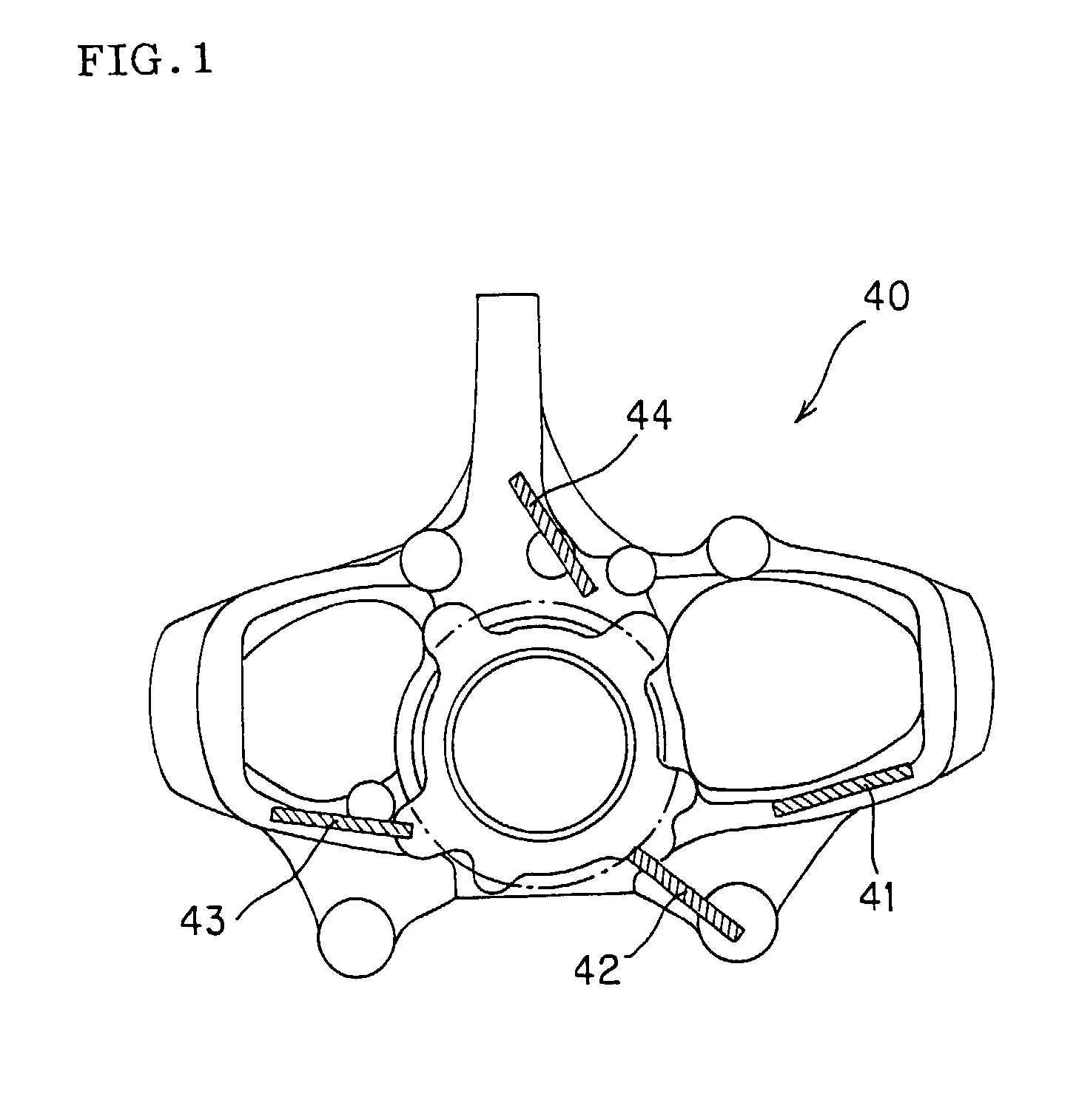

[0061] FIG. 1 is a side view showing one example of the aluminum casting forged product in accordance with the present invention, showing a steering knuckle 40, which is an automobile part.

[0062] A small amount of manganese was added to scraps of A6061 alloy to prepare a raw material containing 0.6 wt % silicon, 0.8 wt % magnesium, 0.2 wt % copper, and 0.03 wt % manganese. Using this raw material, the steering knuckle 40 having a shape shown in FIG. 1 was manufactured by observing the steps described below.

[0063] After the raw material was melted at a molten metal temperature of 728.degree. C. to obtain molten metal, a raw material for forging having a shape with a compression ratio of 30% when the shape of final steering knuckle 40 was taken as 100% was molded at a mold temperature of 100.degree. C. Next, closed die forging was performed by using a forging press at a rough forging temperature of 395.degree. C. (surface temperature) by applying a rough forging load of 2770 tons to o...

example 2

[0066] A steering knuckle was manufactured in the same way as in Example 1 except that the temperature condition and load condition were changed so that the molten metal temperature is 720.degree. C., the mold temperature is 125.degree. C., the rough forging temperature is 400.degree. C., the rough forging load is 2730 tons, the finish forging temperature is 445.degree. C., and the finish forging load is 3780 tons, and the mechanical properties were examined.

[0067] The temperature condition and load condition are given in Tables 1 and 2, respectively, and the measurement result of mechanical properties is given in Table 3.

[0068] The results of Examples 1 and 2 reveal that the mechanical properties of the aluminum casting forged product in accordance with the present invention were kept at values higher than the values specified for A6061FD manufactured by the conventional forging process in terms of all of tensile strength, proof stress, and elongation.

example 9

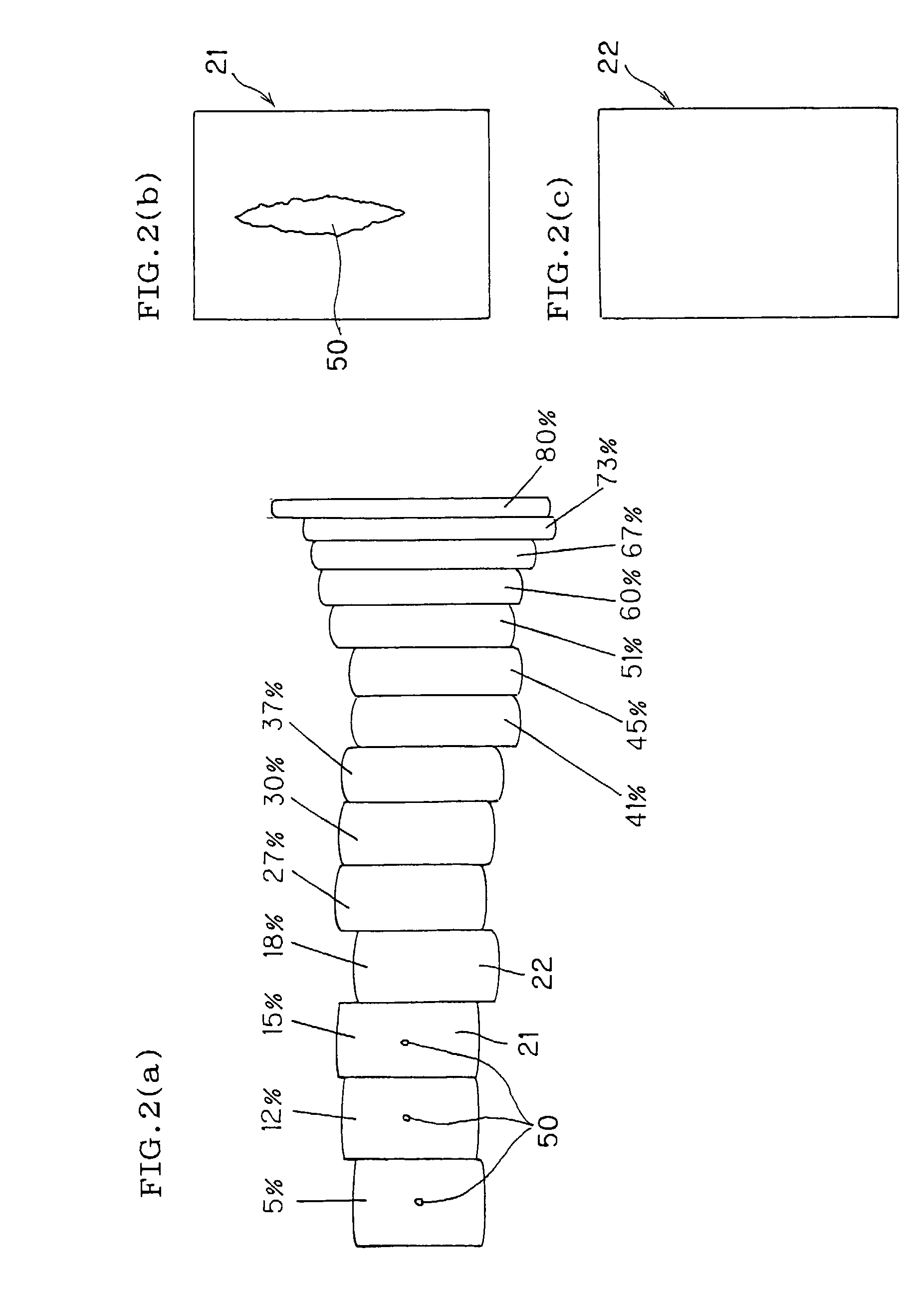

[0069] The same raw material as that in Example 1 was prepared, and a columnar specimen was manufactured. After the raw material was melted at a molten metal temperature of 728.degree. C. to obtain molten metal, a raw material for forging was molded. At the time of forging, the compression ratio was changed to 5%, 12%, 15%, 18%, 27%, 30%, 37%, 41%, 45%, 51%, 60%, 67%, 73%, and 80%, and fourteen products were manufactured.

[0070] FIG. 2(a) is a view showing a difference in shape for each compression ratio. For these raw materials (columnar specimens) with a different shape, the interior of each specimen was observed.

[0071] As a result, as shown in FIG. 2(b), for the raw materials for forging with a compression ratio of 13% or less, an internal defect remained. All of the raw materials for forging with a compression ratio of 18% or more were good in quality without defects as shown in FIG. 2(c).

Industrial Applicability

[0072] As described above, according to the present invention, there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com