Array mechanism of laser spot projector with adjustable light spot density

A density and laser technology, applied in the direction of instruments, measuring instruments, active optical measuring devices, etc., can solve the problem that the feature points cannot be extracted, and achieve the effect of solving the problem that cannot be extracted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

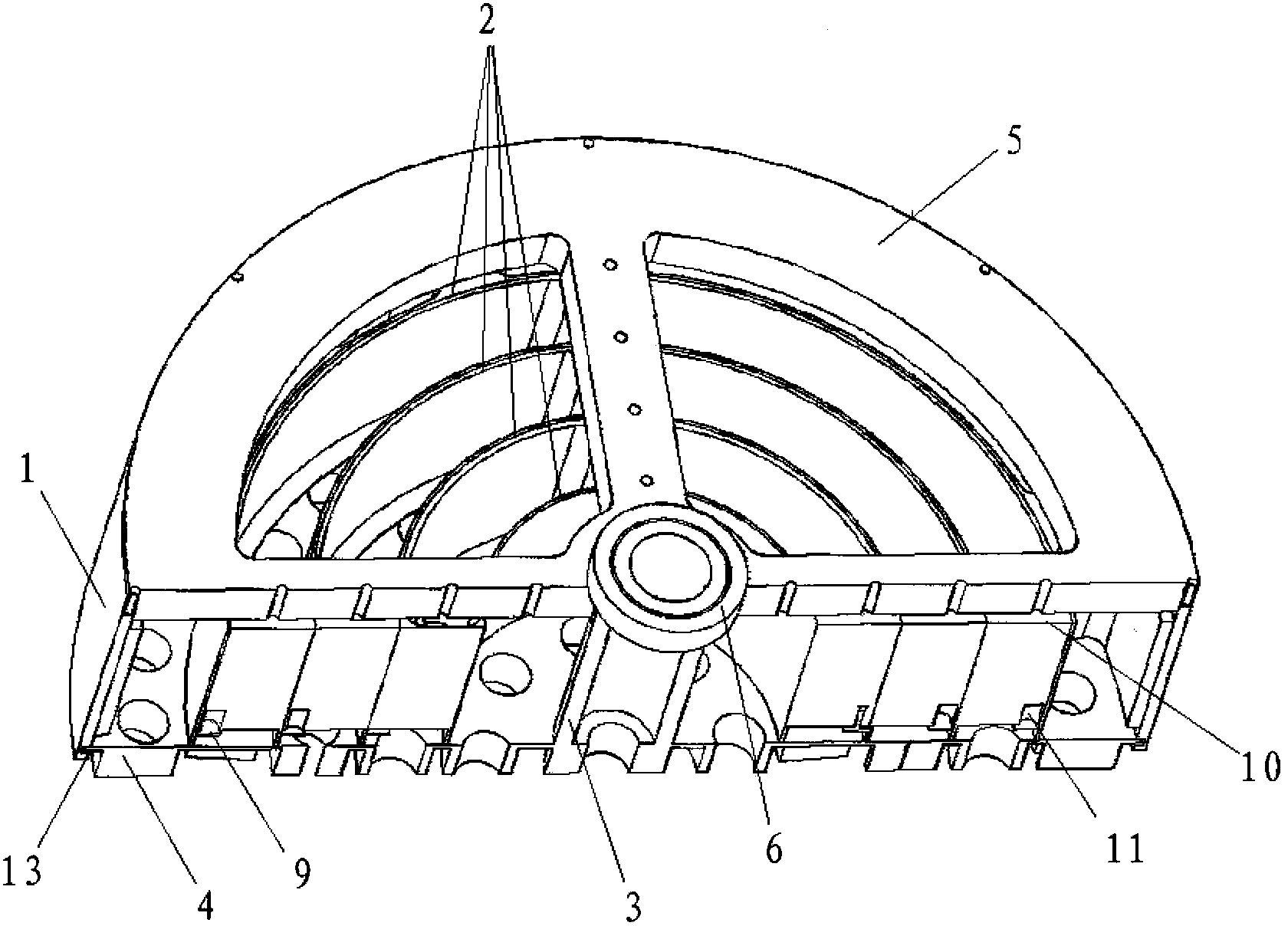

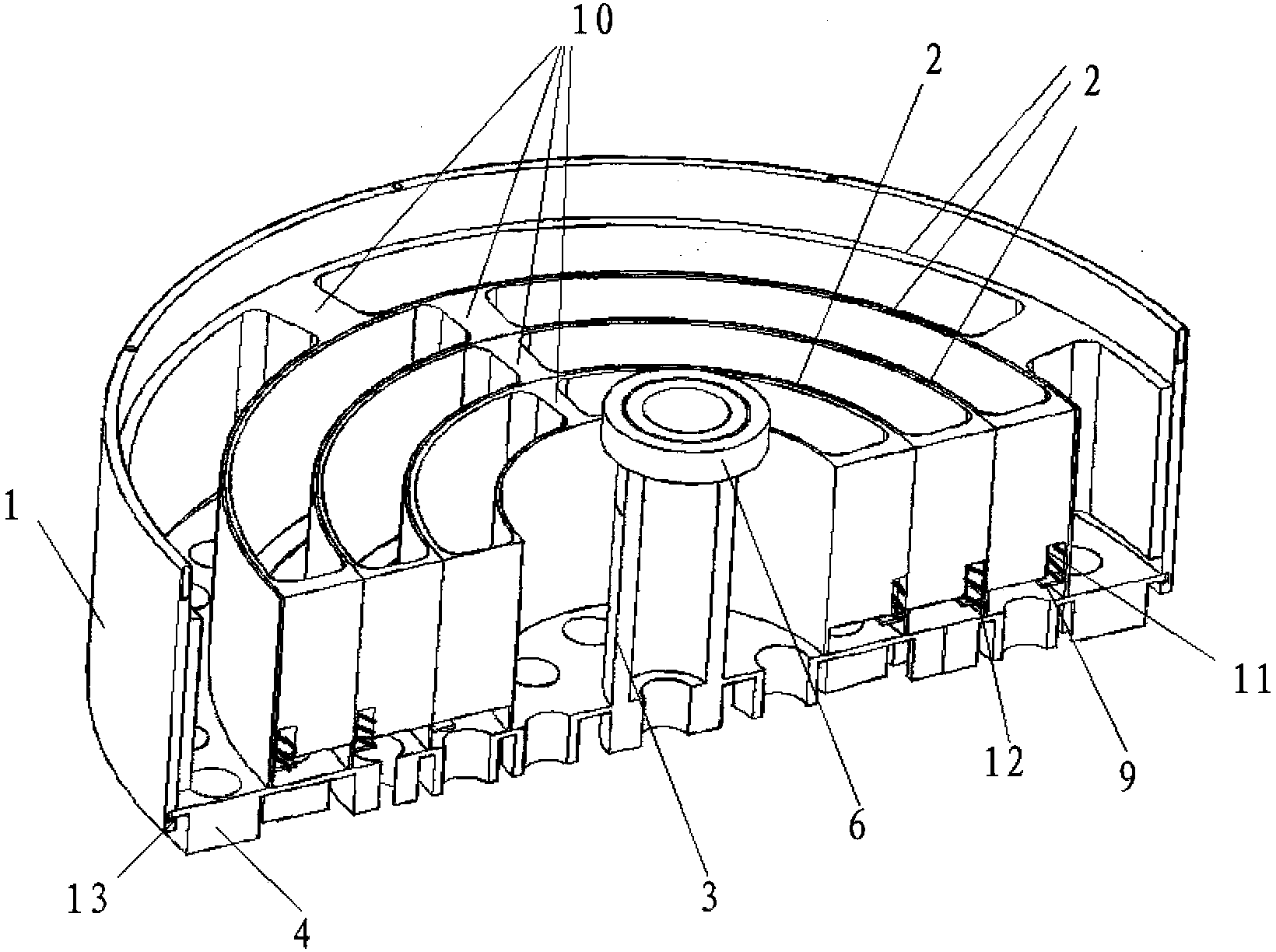

[0022] Such as Figure 1 ~ Figure 4 As shown, the front end of the cylindrical base 1 is fixedly installed with a front end cover 5 through threads, and the rear end cover 4 is fixedly installed at the rear end. An auxiliary support ring 2 is installed in the cylinder base 1 .

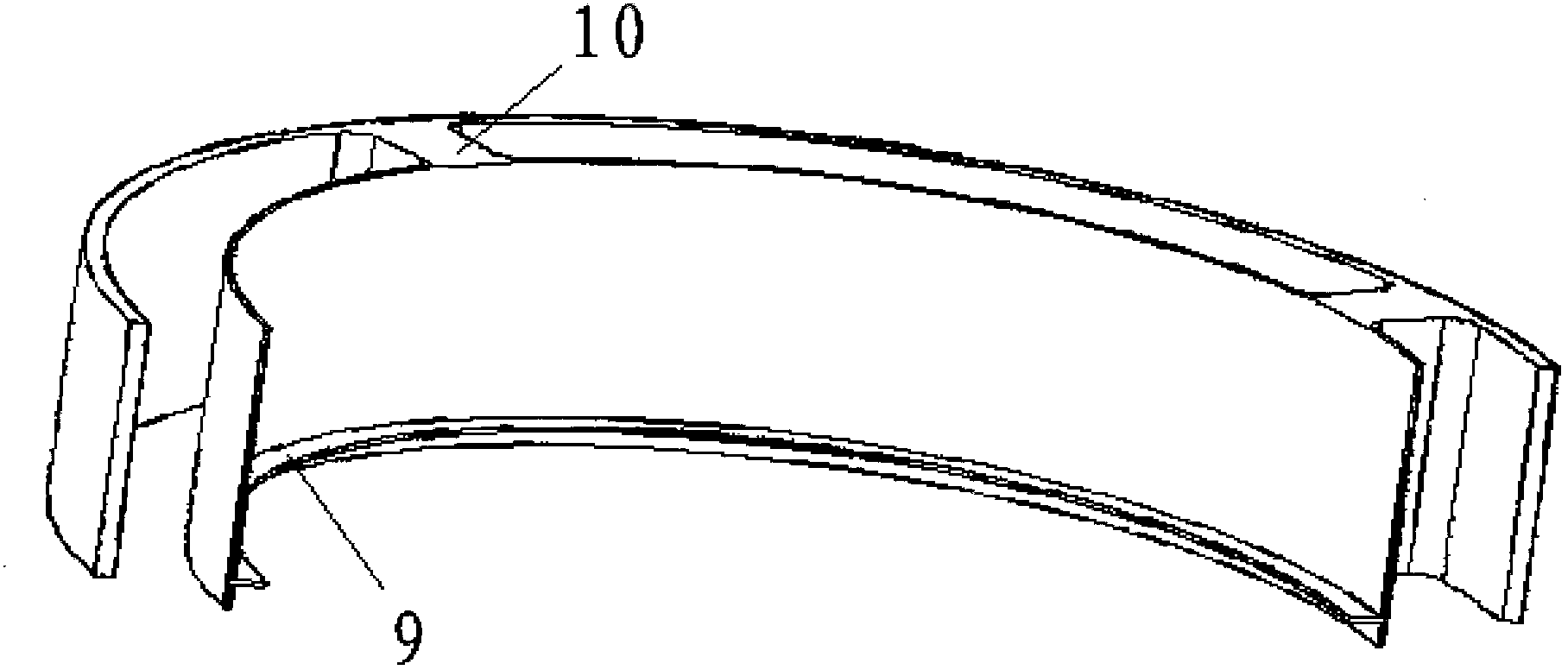

[0023] Such as figure 1 with Figure 4 As shown, the rear end cover 4 is circular, and several circular array blocks 7 are integrally processed on the outer end surface, and the circular array blocks 7 are arranged in circles on the rear end cover 4 to form an annular array. The ring array block 7 forms each circle, and an annular groove 14 is formed between adjacent circles. In the center of the rear end cover 4, a force application rod 3 is integrally processed. One end of the force application rod 3 is circular, and a laser fixing hole 8 is processed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com