Clamp with controllable clamping force and for machining

A clamping force and fixture technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of surface damage of aluminum products, noise from the use of cylinders, waste of resources, etc., to improve processing efficiency and avoid damage , The effect of good pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

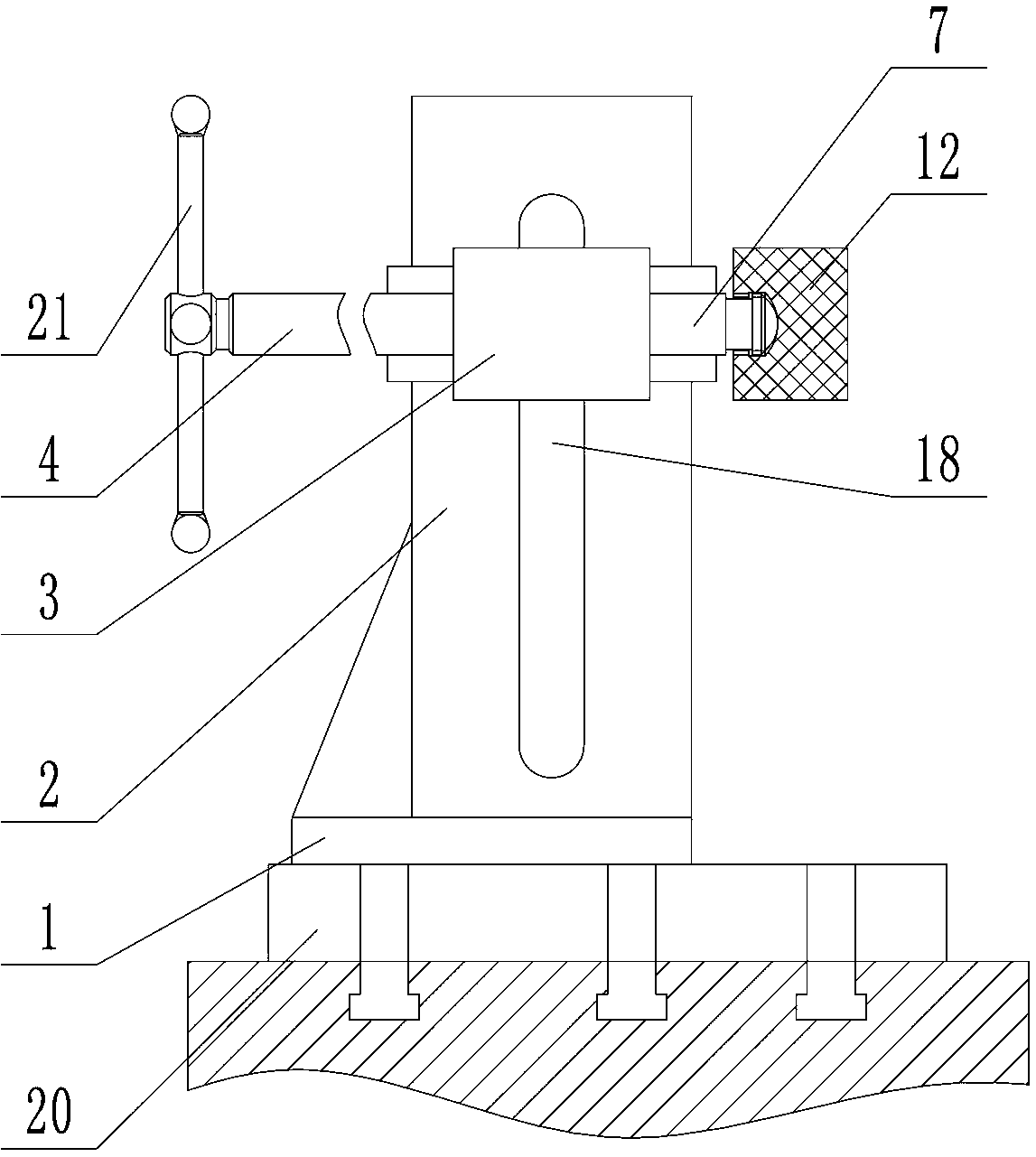

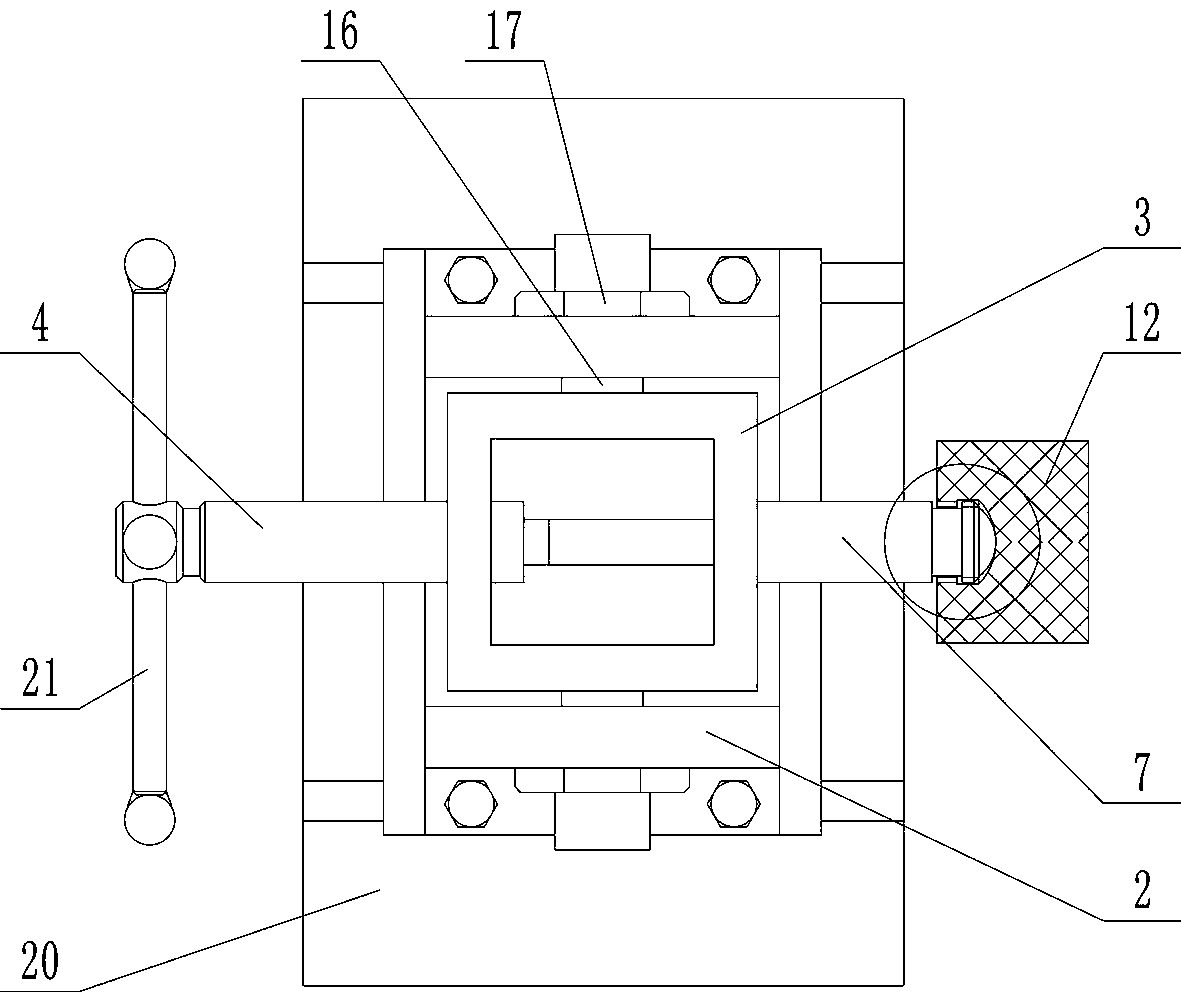

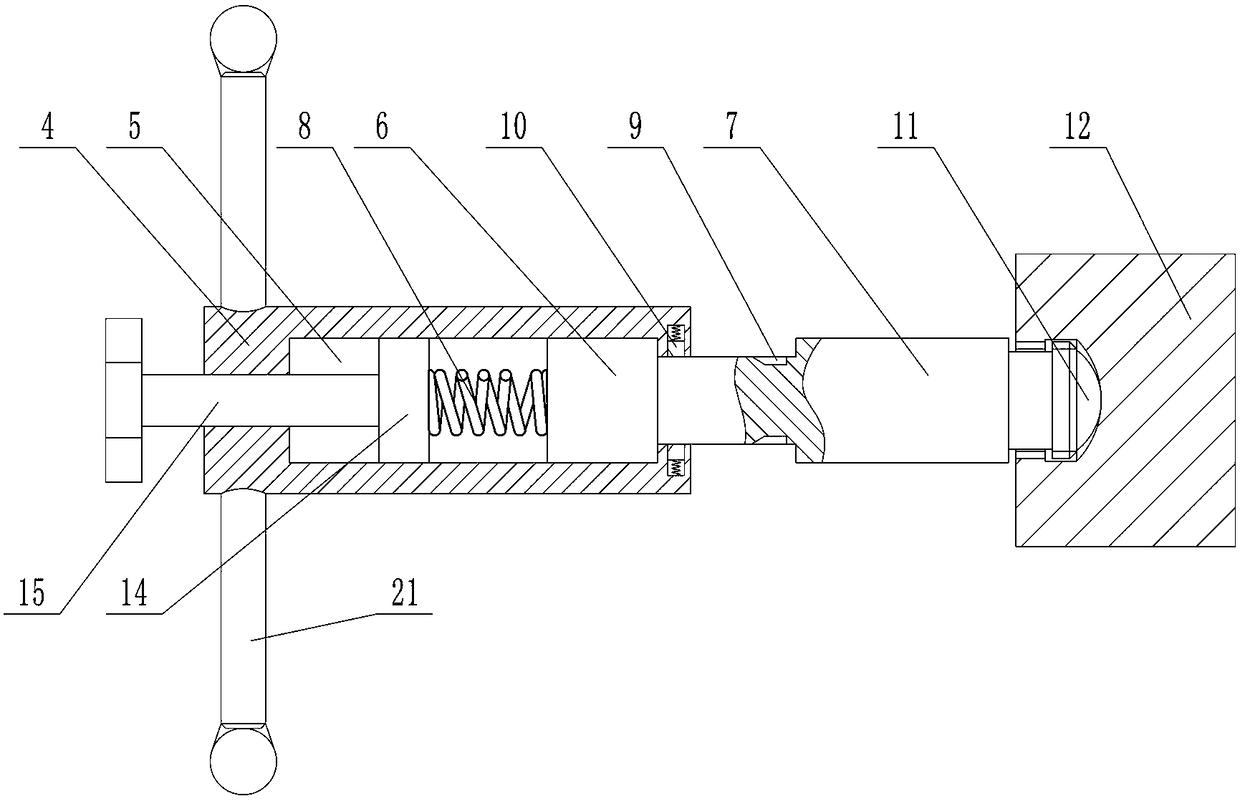

[0016] Depend on Figure 1-6 It can be seen that the present invention includes a horizontally placed base plate 1, two vertical guide plates 2 placed in parallel front and back are provided above the base plate 1, and a slider 3 that can move up and down along the guide plate 2 is provided between the two guide plates 2. The cross section of the slider 3 is in the shape of "back". The left side wall of the slider 3 is interspersed with a screw 4. The screw 4 and the slider 3 are threaded. The right end of the screw 4 is provided with a blind hole 5, and the blind hole 5 A disc 6 that can slide left and right in the blind hole 5 is installed inside, and the disc 6 cannot be separated from the blind hole 5. The right side wall of the slider 3 is interspersed with a push rod 7 that can slide left and right along the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com