Locating tool for pressing locomotive silicon rectifier tube

A technology of positioning tooling and silicon rectification, which is applied in the field of mechanical processing to achieve the effects of high hardness, increased friction, and excellent resistance to compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described below in conjunction with specific embodiment:

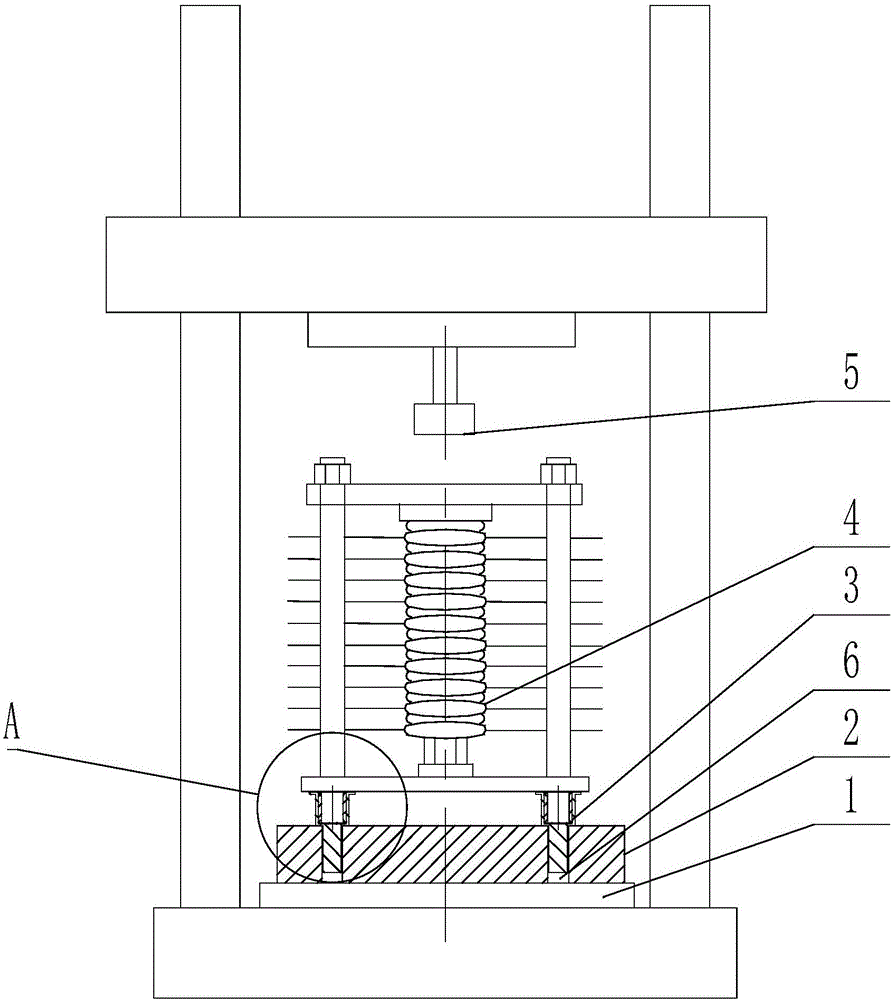

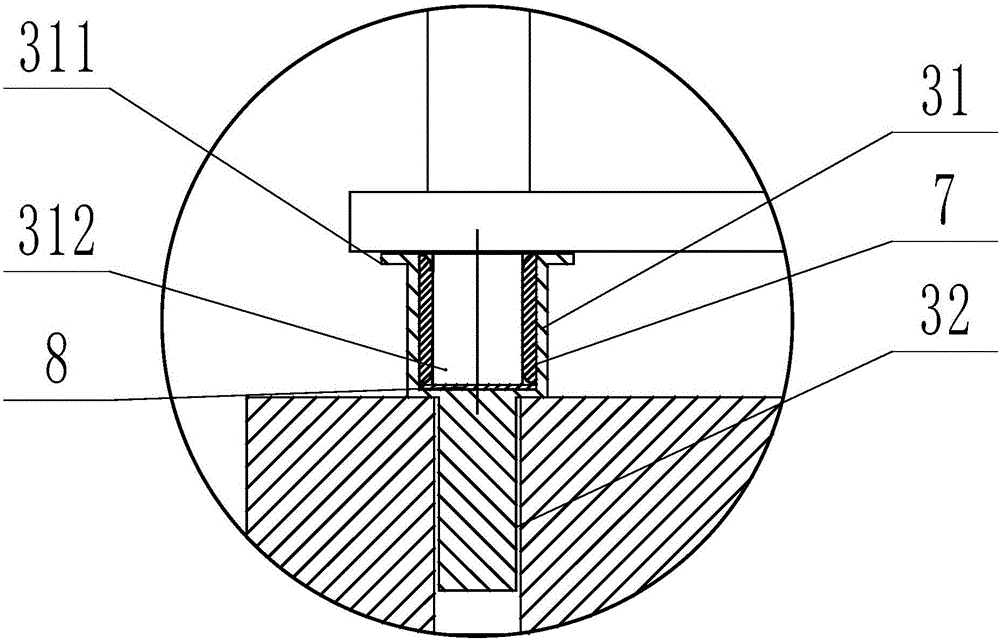

[0020] see figure 1 and figure 2 , a positioning tool for pressing silicon rectifier tubes for locomotives, a backing plate 1 is fixedly arranged on the workbench, a positioning plate 2 is rested on the backing plate 1, the center of the positioning plate 2 is collinear with the center line of the pressure head 5, The positioning plate 2 is provided with the center of the positioning plate 2 as the center of the circle and the circumferentially distributed positioning holes 6, the positioning holes 6 are provided with a support sleeve 3, the support sleeve 3 includes a support sleeve upper part 31 and a support sleeve lower part 32, and the support sleeve upper part The outer diameter of 31 is larger than the outer diameter of the lower part 32 of the support sleeve, the upper part 31 of the support sleeve is provided with a flange 311, and the upper part 31 of the support slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com