A compression device for preventing overpressure

A pressing device and overpressure technology, applied in positioning devices, manufacturing tools, metal processing machinery parts, etc., can solve the problems of large noise, surface damage and waste of resources when using cylinders, achieve good pressing force, avoid The effect of damage and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

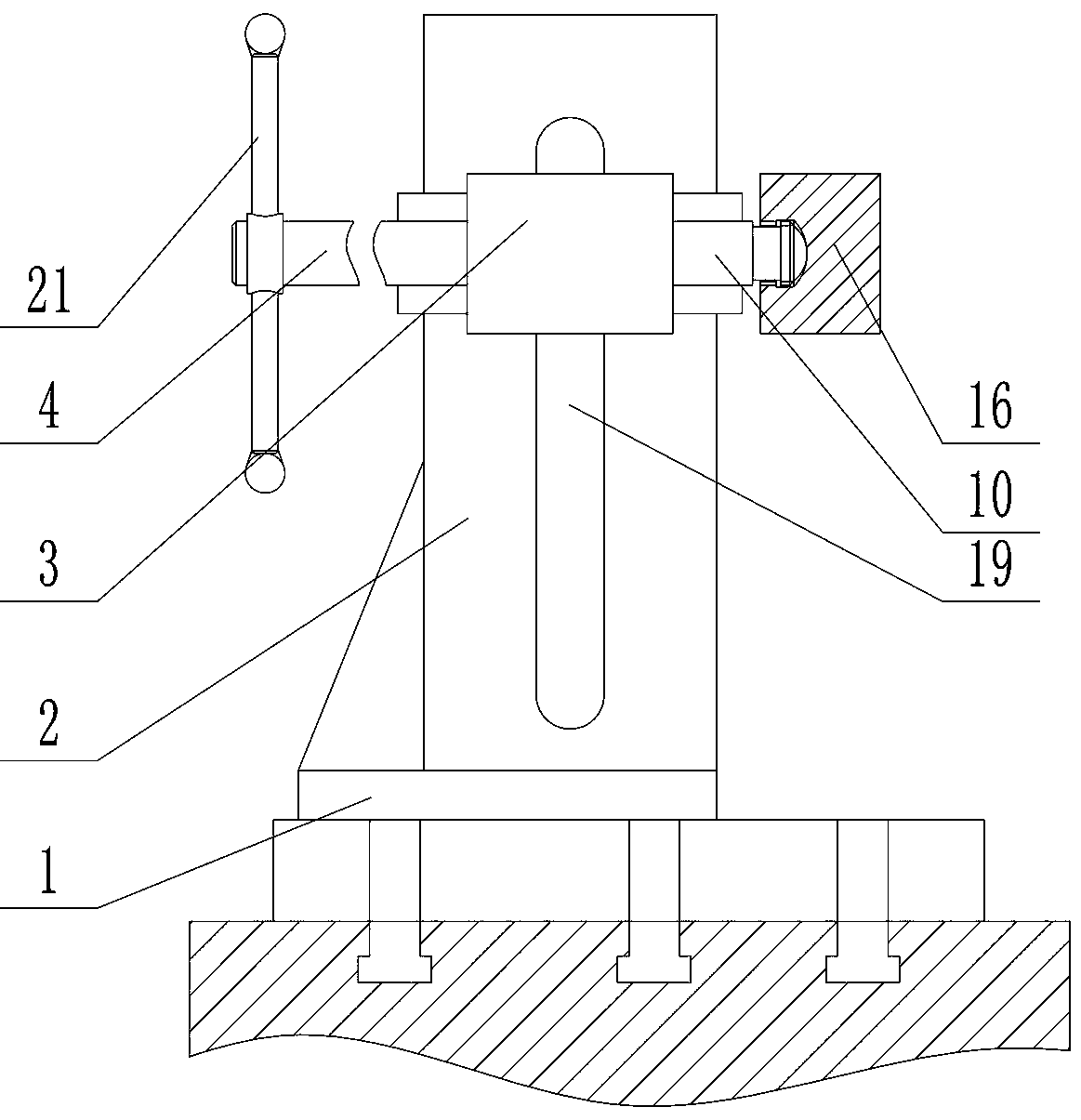

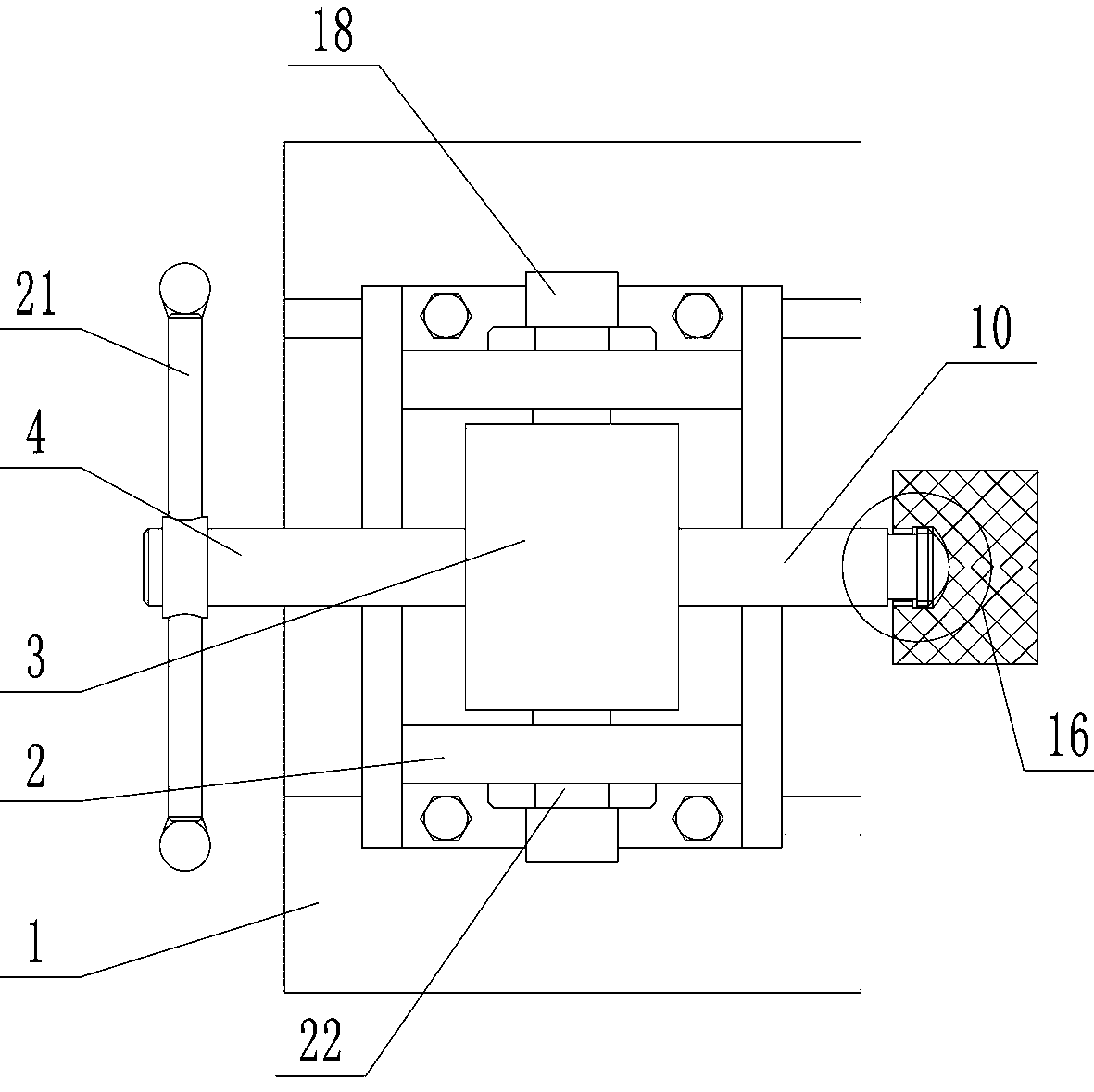

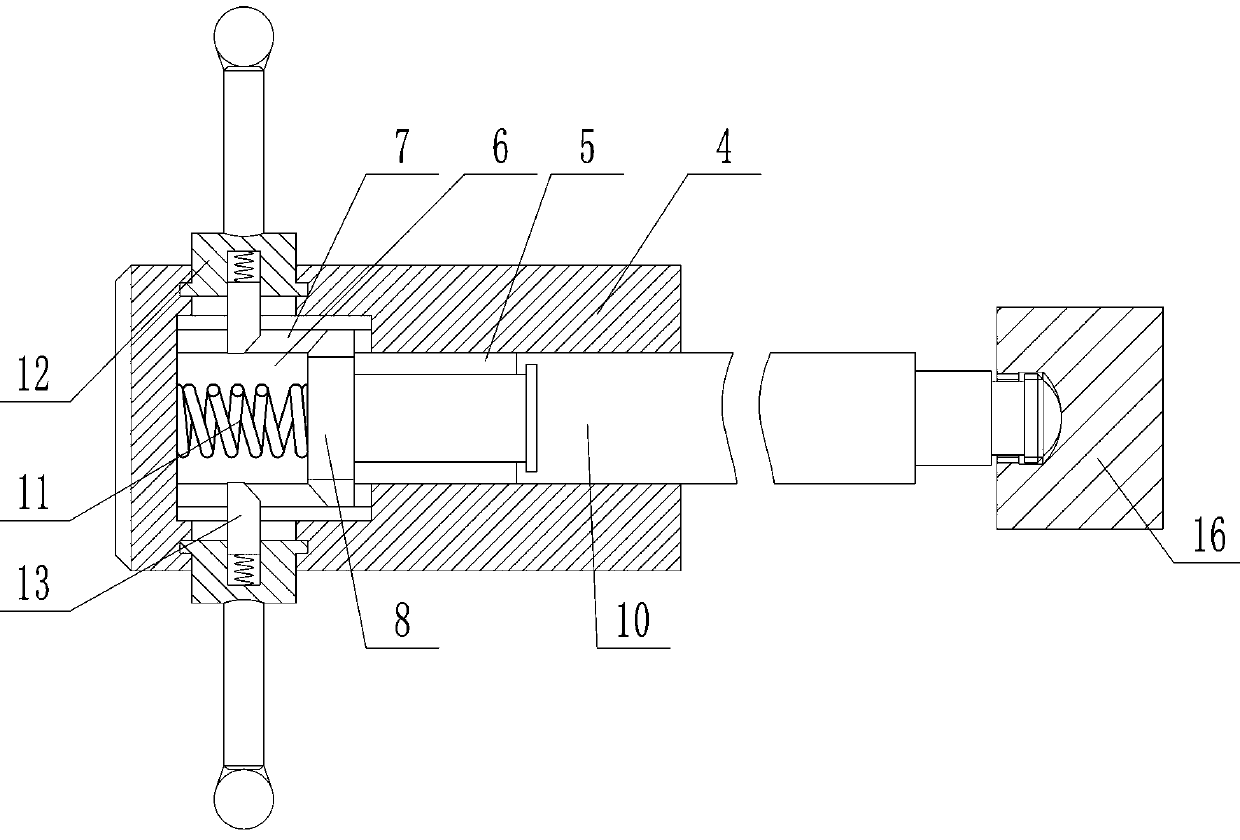

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1-8 It can be seen that the present invention includes a horizontally placed base plate 1, two vertical guide plates 2 placed in parallel front and back are provided above the base plate 1, and a slider 3 that can move up and down along the guide plate 2 is provided between the two guide plates 2. The left and right end surfaces of the slider 3 are interspersed with screw rods 4, and the screw rod 4 and the slider 3 are threadedly connected. The mounting hole 6 connected to the hole 5, the diameter of the mounting hole 6 is greater than the diameter of the blind hole 5, the side wall of the mounting hole 6 is provided with axially distributed and circumferentially uniform chute 7, the mounting hole 6 is provided with a Slide the movable disc 8 left and right in the hole 6, and the outer edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com