Treasury door locking mechanism

A locking mechanism, a technology for vault doors, applied in building structures, building fastening devices, buildings, etc., can solve the problems of inconvenient door opening, high strength requirements, small transmission force, etc., and achieve increased reliability and safety. High and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

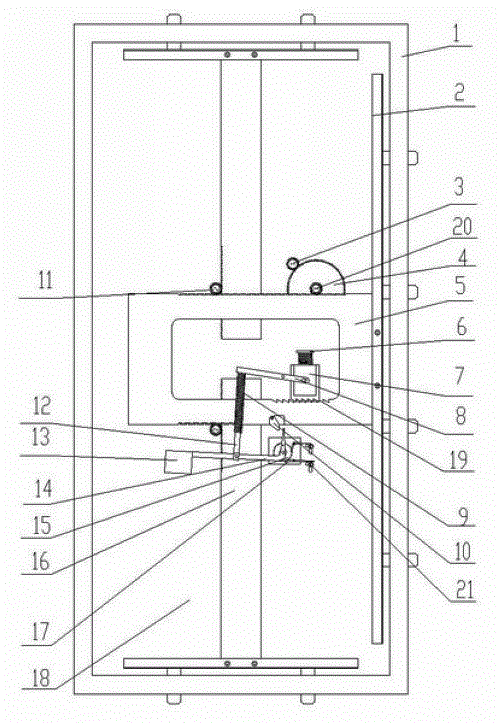

[0015] Such as figure 1 Shown, the present invention comprises storehouse door 18 and door frame 1, and the handwheel of storehouse door 18 outsides is connected with the gear 3 of storehouse door 18 inboards, and gear 3 meshes with transmission gear one 4, and the pinion 20 on the transmission gear one 4 and main One end of the rack of the locking part 5 engages, and the other end of the rack of the main locking part 5 engages with the upper and lower bolts 16 respectively through the transmission gear 211, and one side of the main locking part 5 is equipped with a lock. Tongue 2; the main locking part 5 cooperates with the locking linkage part, and the ends of the upper and lower dead bolts 16 and the dead bolt 2 are inserted in the door frame 1, and the vault door is locked.

[0016] The main locking part 5 meshes with the helical tooth block 7 of the locking linkage part through the helical teeth 19 thereon, the helical tooth block 7 is connected with one end of the lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com