Low pressure chromatography column

A technology of low-pressure chromatography and piston components, which is applied in the direction of chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve the problems of inconvenient use, insufficient filtration, and inconvenient adjustment of column bed height, etc., to improve the use Long service life, good filtration effect, and pressure equalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

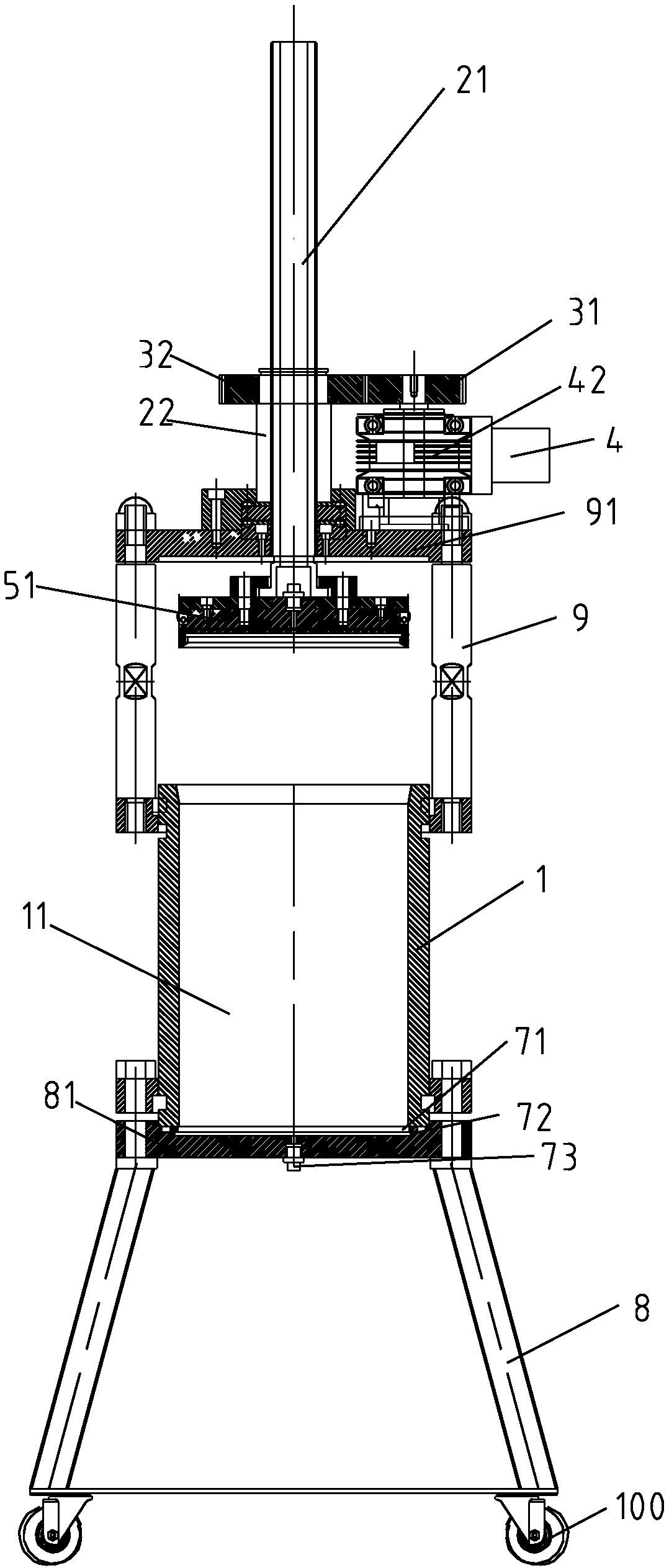

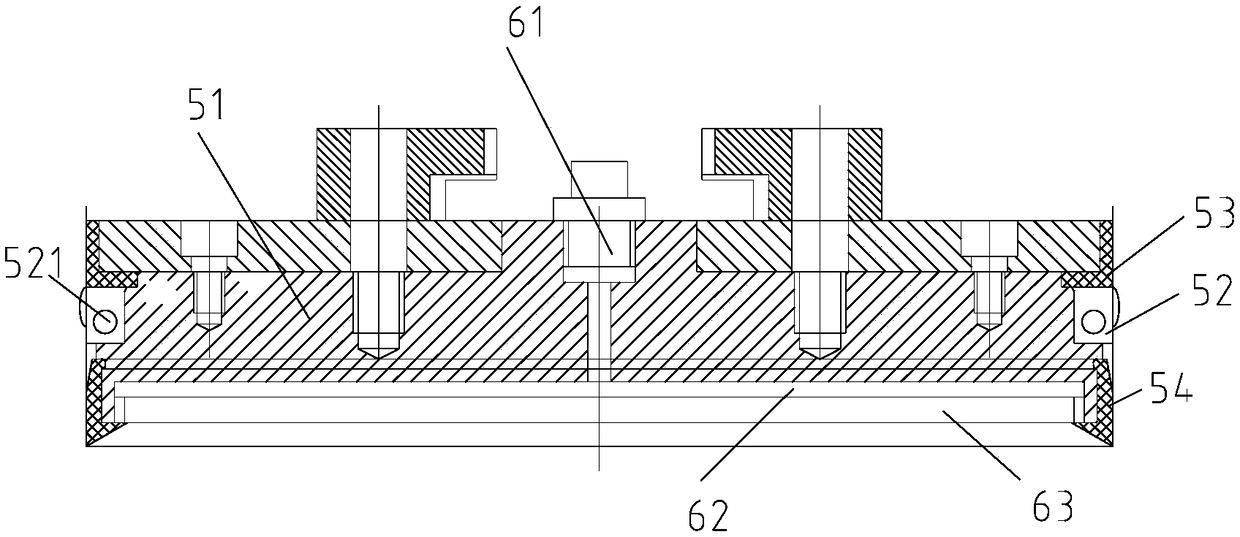

[0023] Such as figure 1 , 2 Shown, a kind of low-pressure chromatography column, it comprises body, it also comprises:

[0024] A cylinder body 1, the cylinder body 1 is provided with a filler chamber 11 for accommodating fillers;

[0025] The piston part includes a piston assembly and is connected with the piston assembly so as to drive the piston assembly to move, so that the piston assembly is pressed into the packing chamber 11 and acts on the packing. The piston assembly is provided with a piston assembly for pressing the piston assembly When the inlet is in place, the liquid phase is guided to the upper surface of the packing in the packing cavity;

[0026] A liquid distribution assembly for collecting the liquid phase flowing out of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com