Strip-shaped polishing machine

A polishing machine and belt-like technology, applied in the field of polishing machines, can solve the problems of unusable rollers, failure to achieve secondary use of polishing, and damage to rollers, so as to provide speed and efficiency, shorten polishing time, and improve speed. and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

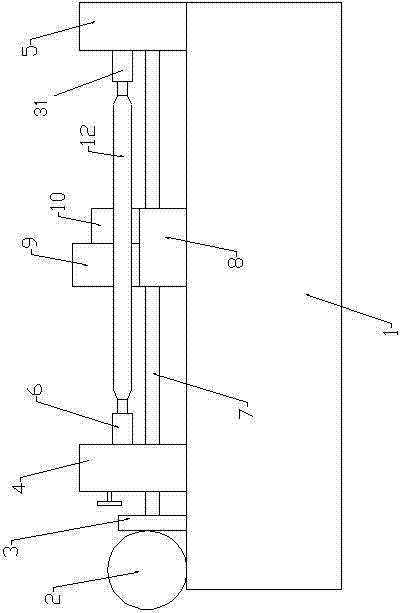

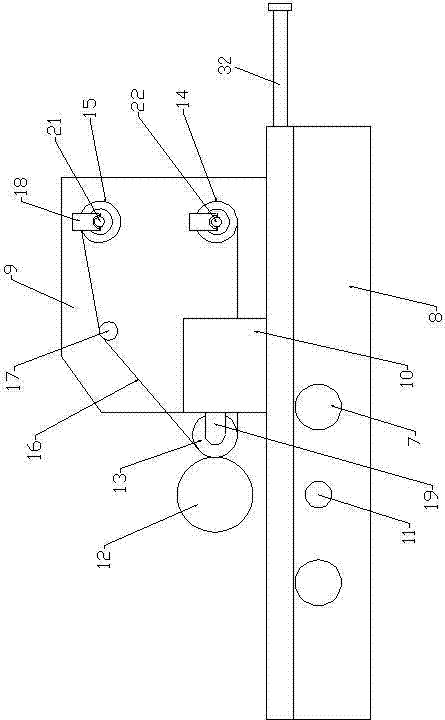

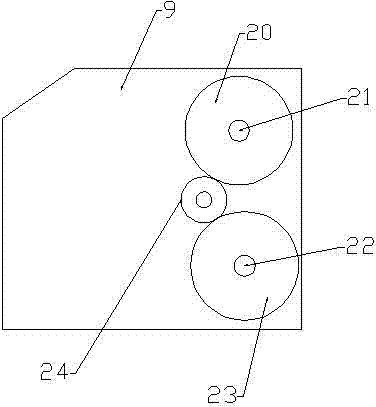

[0017] Such as figure 1 , 2 , 3, 4, and 5, a belt polishing machine includes a base 1, a propulsion motor 2 installed on the base 1, a first stroke support 3 and a second stroke support 5 arranged on one side of the propulsion motor 2, The guide rod 7 that is installed between the first stroke bracket 3 and the second stroke bracket 5 and the stroke propelling screw 11, the roller movable bracket 4 that is sleeved on the guide rod 7 and the stroke propelling screw 11 outside, and the roller movable bracket 4 The connected roller rotation drive shaft 6, the roller rotation driven shaft 31 installed on the top of the second stroke bracket 5, the polishing machine base 8 installed between the roller movable bracket 4 and the second stroke bracket 5, the described The polishing machine base 8 is sleeved on the outside of the guide rod 7 and the stroke propelling screw 11, a polishing transmission housing 9 and a polishing output housing 10 are arranged above the polishing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com