Inversion type mobile phone 3D curved surface polishing machine

A polishing machine and indexing technology, applied in the field of polishing machines, can solve the problems of slump, glass covering, long time for loading and unloading products, etc., and achieve the effect of ensuring polishing quality, ensuring uniformity and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

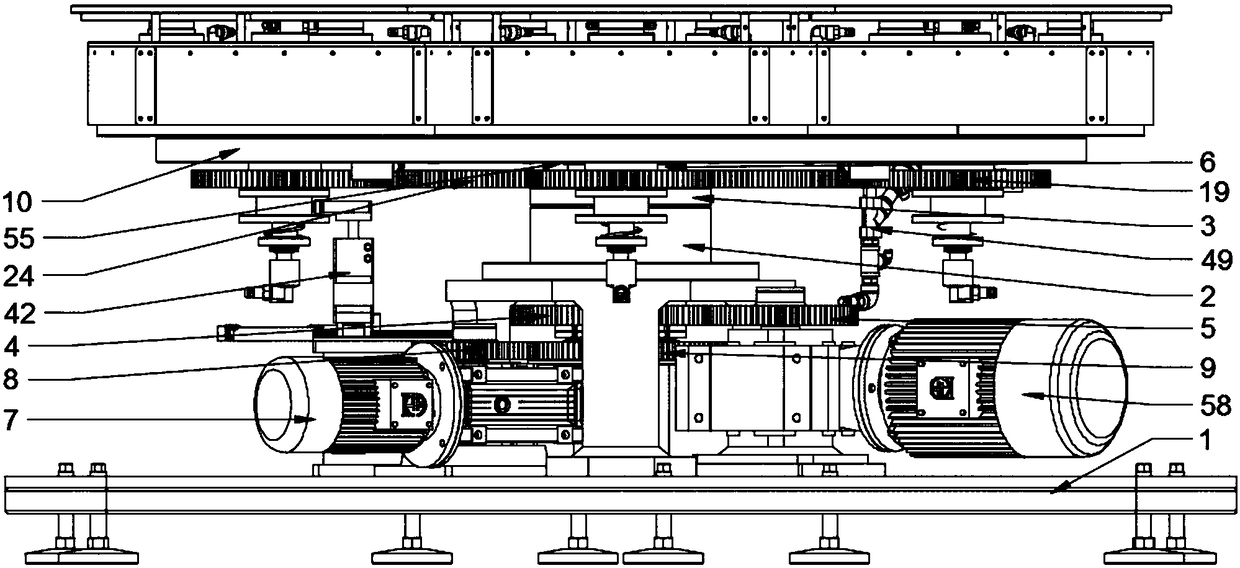

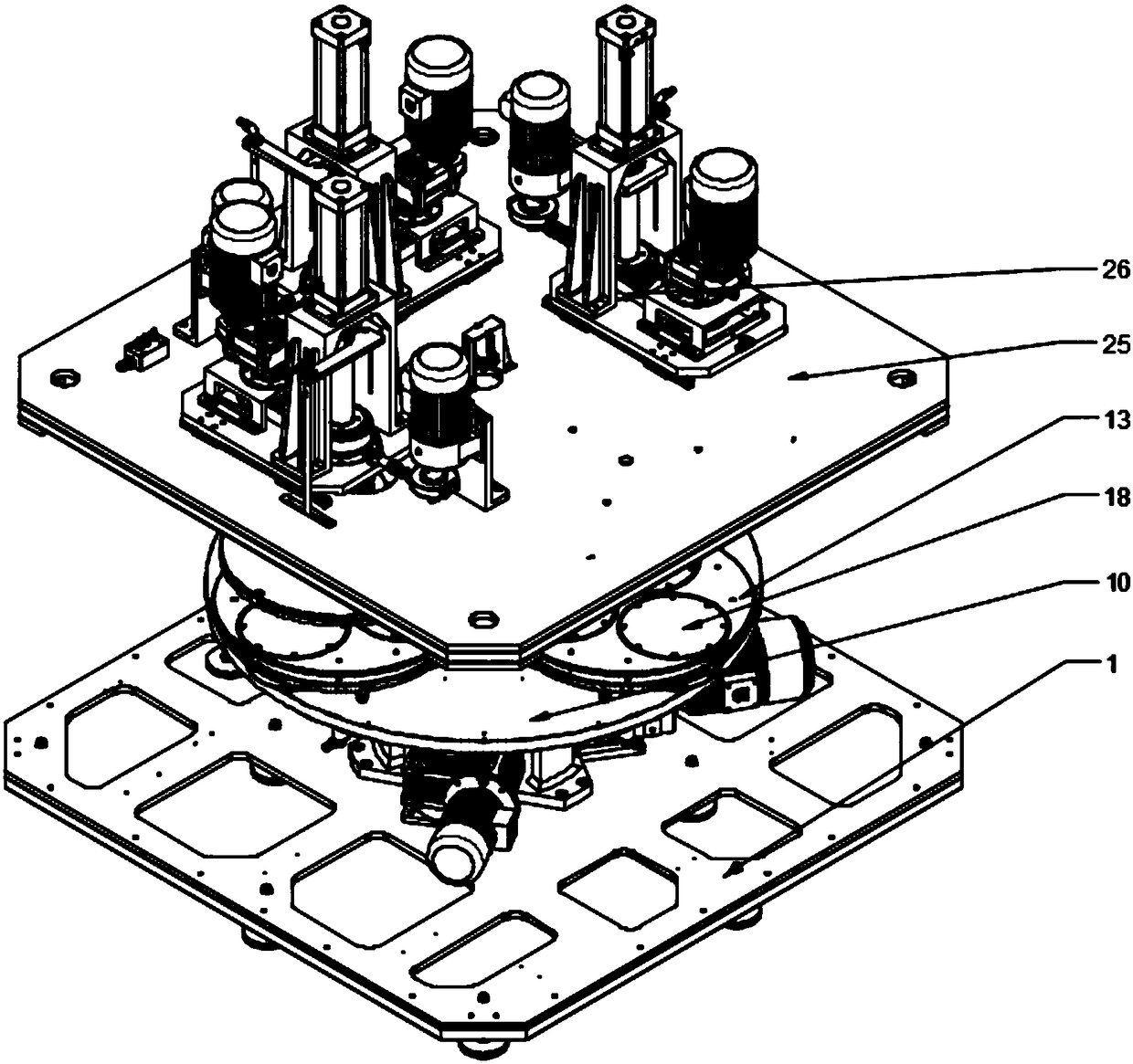

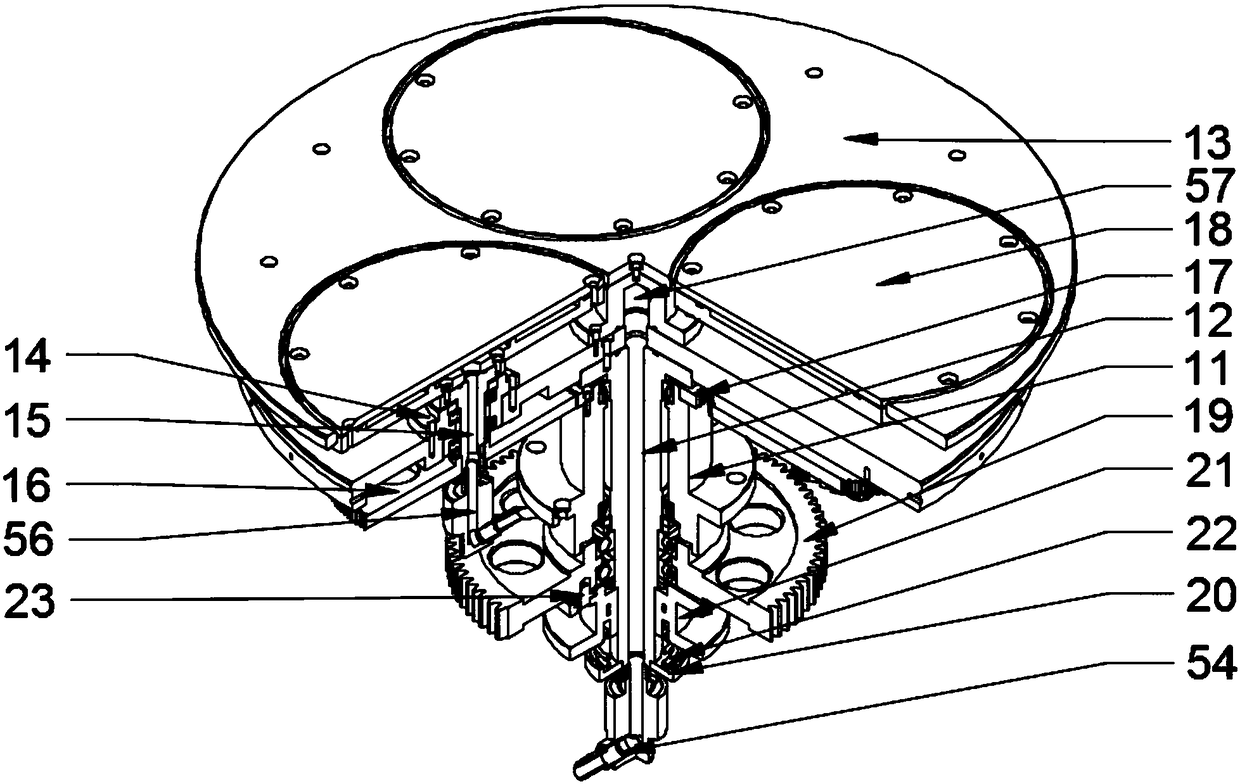

[0018]An indexable mobile phone 3D curved surface polishing machine, including a base 1, characterized in that: the base 1 is provided with a connecting seat 2, the connecting seat 2 is provided with a sun shaft 3, and the sun shaft 3 is connected to the Seat 1 2 is connected by rotation and bearings are provided at the joint. The base 1 is provided with a revolution and rotation conjoined reducer 58. The sun shaft 3 and the revolution and rotation conjoined reducer 58 are gear transmissions. The sun shaft 3 is provided with Gear three 4, revolution and rotation conjoined reducer 58 are provided with gear four 5, the sun shaft 3 and revolution and rotation conjoined reducer 58 are transmitted through gear three 4 and gear four 5, revolution and rotation conjoined reducer 58 turns to drive the sun shaft 3 to rotate. The sun shaft 3 is provided with a central s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com