Circular plate type automatic polishing machine

A technology of automatic polishing and polishing mechanism, which is used in surface polishing machine tools, grinding/polishing equipment, automatic grinding control devices, etc., can solve the problem of low work efficiency, inability to realize automatic compensation of grinding wheel wear, and poor polishing surface quality. Guarantee and other issues to achieve the effect of improving production efficiency, ensuring polishing quality, and improving polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

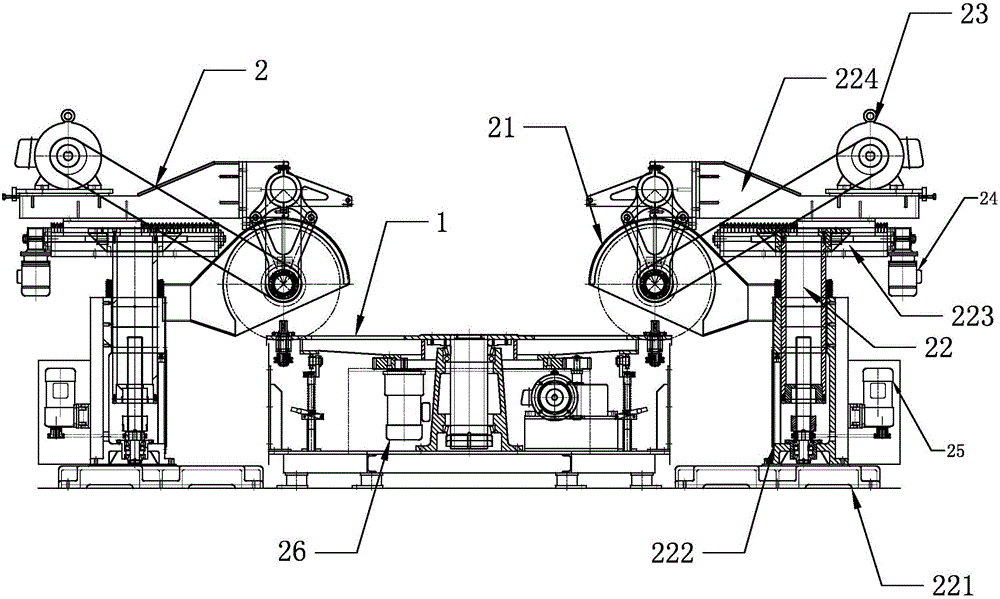

[0015] refer to figure 1 , the disc automatic polishing machine of the present invention includes a mounting table 1 for installing a workpiece and a polishing mechanism 2 for polishing the workpiece, and the polishing mechanism 2 includes a polishing wheel 21 and a frame 22 for installing the polishing wheel 21, The mounting table 1 is a rotatable disc, and the frame 22 includes a fixed base 221, on which a column 222 is installed, and the column 222 can slide back and forth along the surface of the base 221, and the column 222 The first support frame 223 that can move up and down along the column 222 is sleeved, the polishing wheel 21 is installed on the first support frame 223, and the upper surface of the first support frame 223 is equipped with a The second supporting frame 224 of action, described second supporting frame 224 is provided with the first motor 23 that drives polishing wheel 21 to rotate, preferably, described second supporting frame 224 is connected and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com