Multi-station automatic round head connecting pipe polishing equipment

An automatic polishing, multi-station technology, used in grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problems of polishing machine without protective cover, polluted air, and high polishing rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

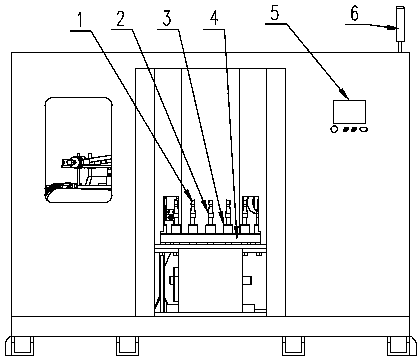

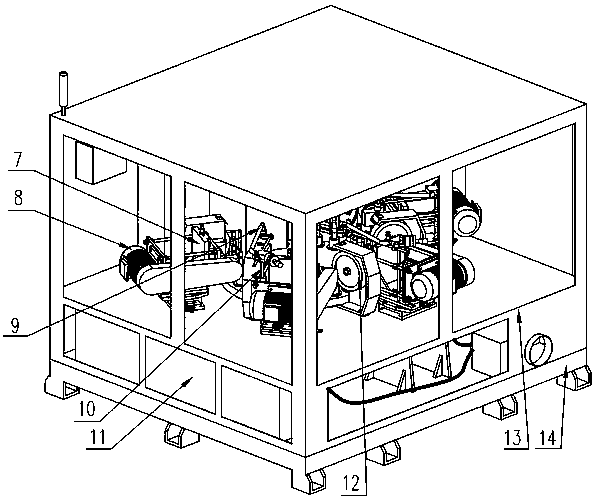

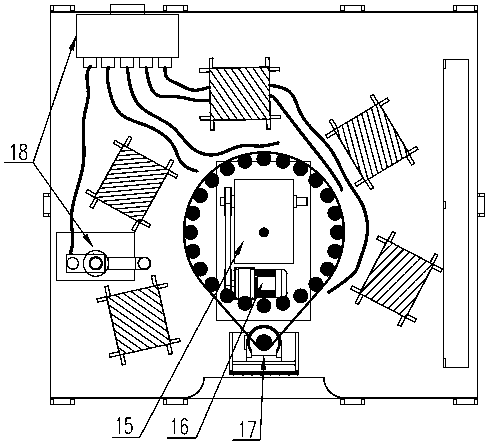

[0016] The multi-station automatic polishing equipment of the present invention includes a positioning fixture 2, a fixture rotating shaft 3, a disc workpiece table 4, a control panel 5, a slide table 7, a motor 8, an automatic wax spraying device 9, a bracket 10, and an electric motor. Box 11, polishing wheel 12, machine tool base 14, divider 15, first servo motor 16, second servo motor 17, wherein positioning fixture 2 is fixed on the fixture rotating shaft 3, workpiece 1 is installed on the positioning fixture 2, and the fixture The rotating shaft 3 is installed on the disc workpiece table 4; the output shaft of the first servo motor 16 is connected with the input shaft of the splitter 15, and the disc workpiece table 4 is installed on the output shaft of the splitter 15, and the output shaft of the first servo motor 16 The output shaft drives the divider 15 to rotate to realize the 4-degree rotary motion of the disc workpiece table; the second servo motor 17 drives the clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com