End point detection method and system and chemical mechanical planarization device

An end-point detection and end-point technology, used in grinding devices, grinding machine tools, electrical components, etc., can solve the problems of complex polishing process, misjudgment, inaccurate judgment of polishing end point, etc., and achieve the effect of ensuring polishing quality and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

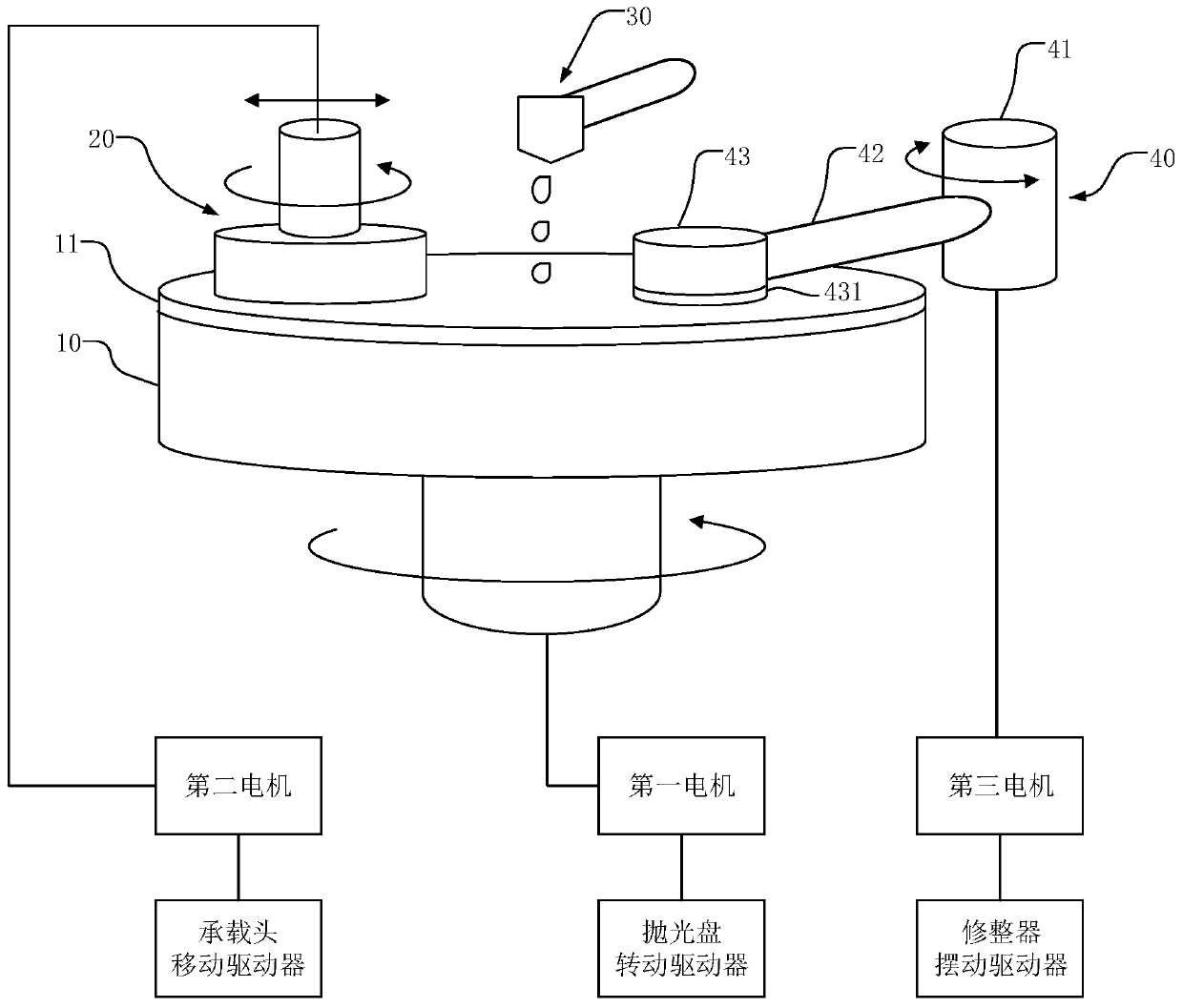

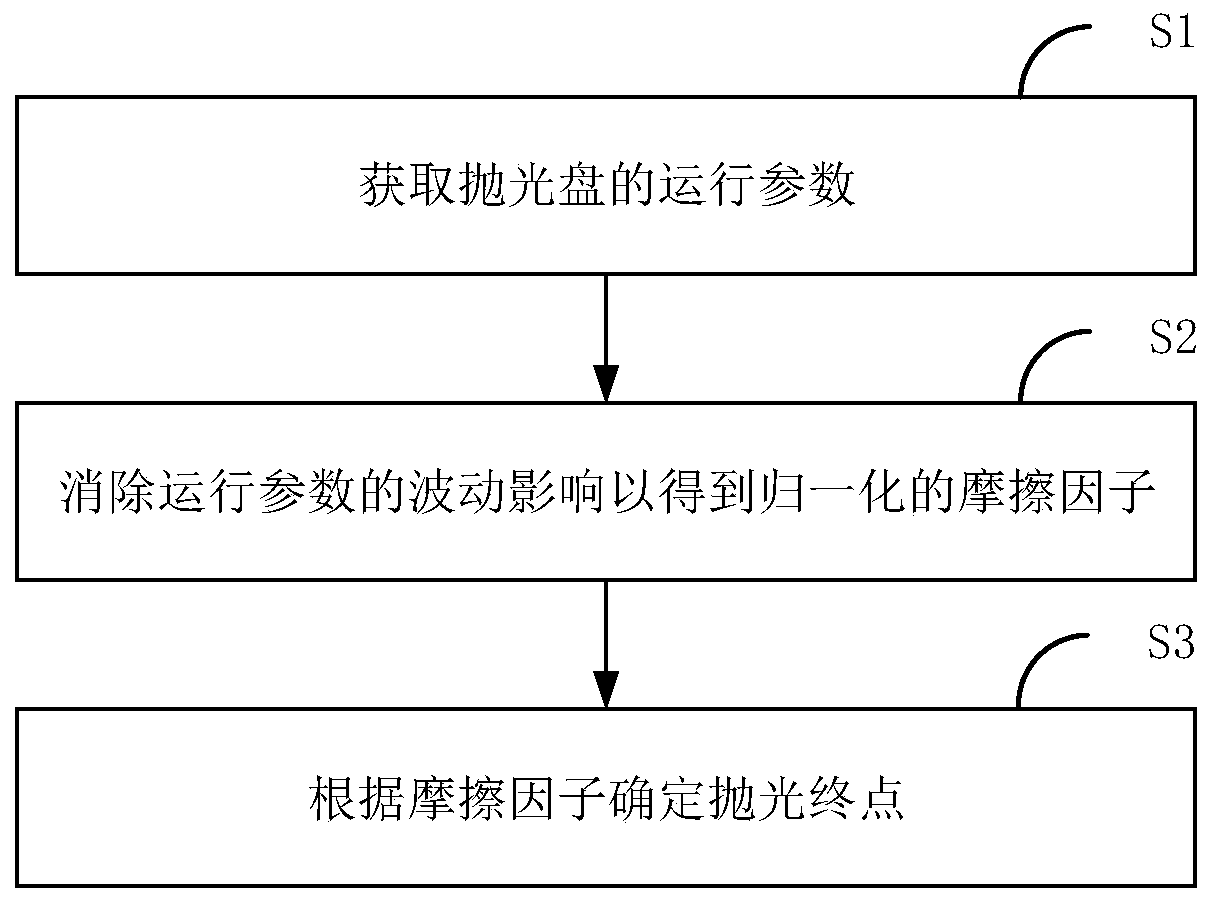

[0078] As a possible implementation of the present invention, step S2 includes:

[0079] Step S21, acquiring the load parameters of the polishing disc 10 and the motion parameters of the carrier head 20 and / or the motion parameters of the dresser 40;

[0080] Step S22 , eliminating the influence of the motion parameters of the carrier head 20 and / or the motion parameters of the trimmer 40 on the load parameters from the load parameters.

[0081] Wherein, the load parameters include load rate, load power, torque and / or motor current of the first motor used to drive the polishing disc 10 to rotate.

[0082] During polishing, the carrying head 20 performs reciprocating horizontal movement along the radial direction of the polishing disc 10, and the dressing head 43 performs reciprocating swinging motion according to the trajectory from the center of the polishing pad to the edge, and these movements will bring periodicity to the load parameters of the polishing disc 10. The sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com