Method and device for polishing automobile hubs

A technology of automobile wheel hub and polishing device, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding workpiece supports, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

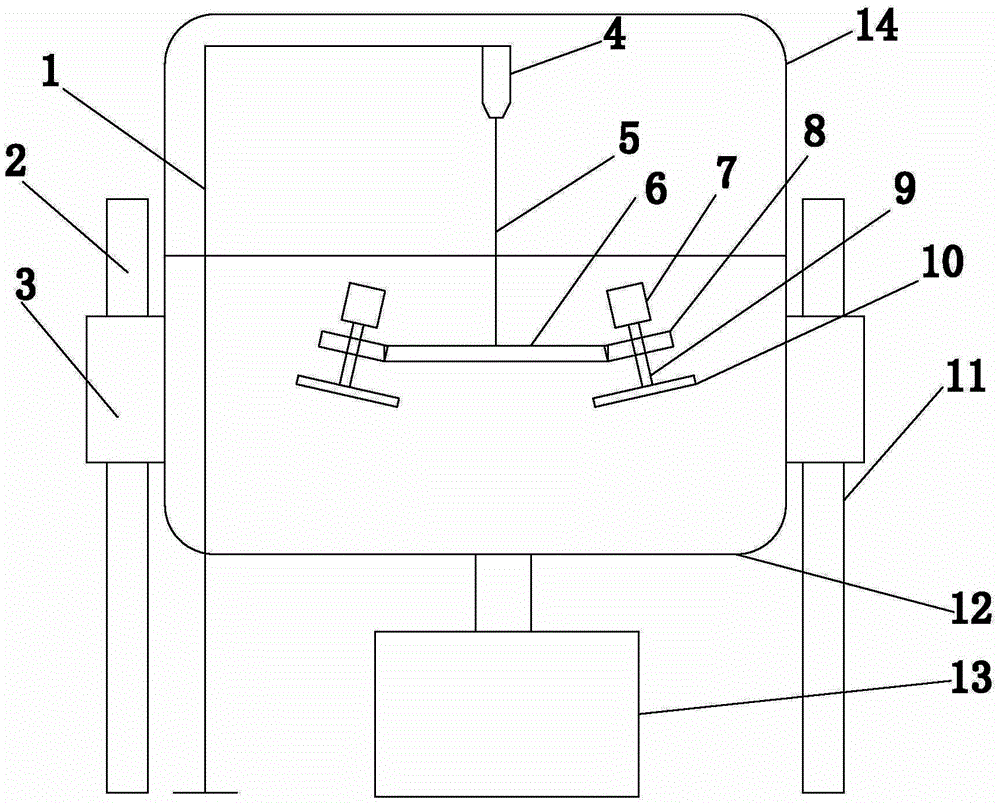

[0019] Example. A kind of automobile wheel hub polishing method, comprises the following steps:

[0020] (1) Drive the inclined car hub to rotate by the rotating device, and let the car hub revolve around the rotating device at the same time;

[0021] (2) Raise the polishing tank to make the first rough polishing of the car wheel hub that rotates and revolves around the rotating device and the rough polishing abrasive;

[0022] (3) Carry out the second fine polishing with the fine polishing abrasives of the automobile wheel hub that rotates and revolves around the rotating device;

[0023] (4) Carry out the third bright polishing with the bright polishing abrasive on the automobile wheel hub that rotates and revolves around the rotating device.

[0024] The rotation speed of the automobile hub is 70-80 r / min.

[0025] The revolution speed of the automobile wheel hub around the rotating device is 45-50 r / min.

[0026] The inclination angle of the obliquely arranged automobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com