Vertical axis counterweight device for complex curve multi-axis linkage processing machine tool

A technology for multi-axis linkage and machining of machine tools, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as center of mass deviation, limited bearing capacity of linear motor platforms or ball screw guide rails, etc. Protection integrity, low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

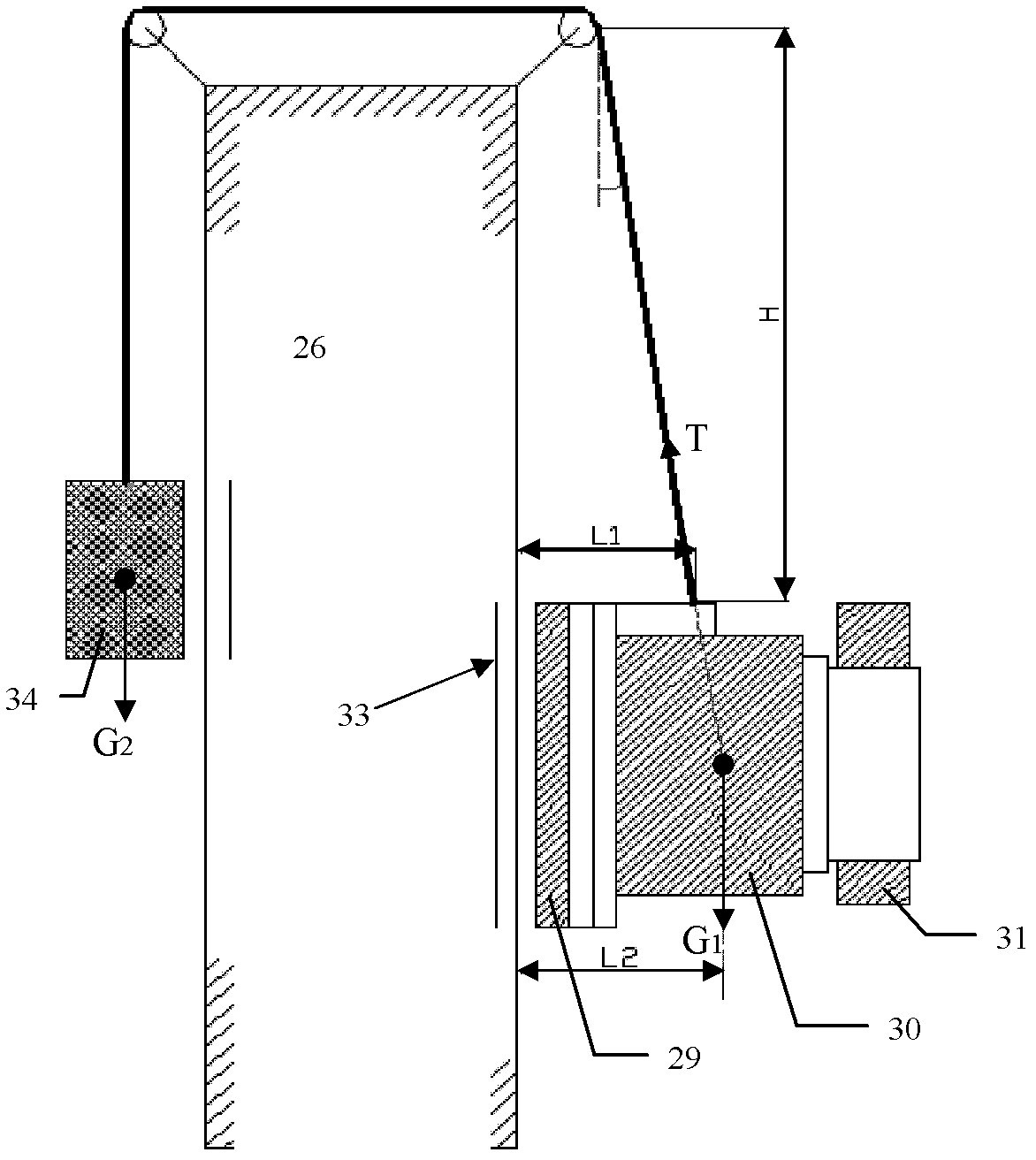

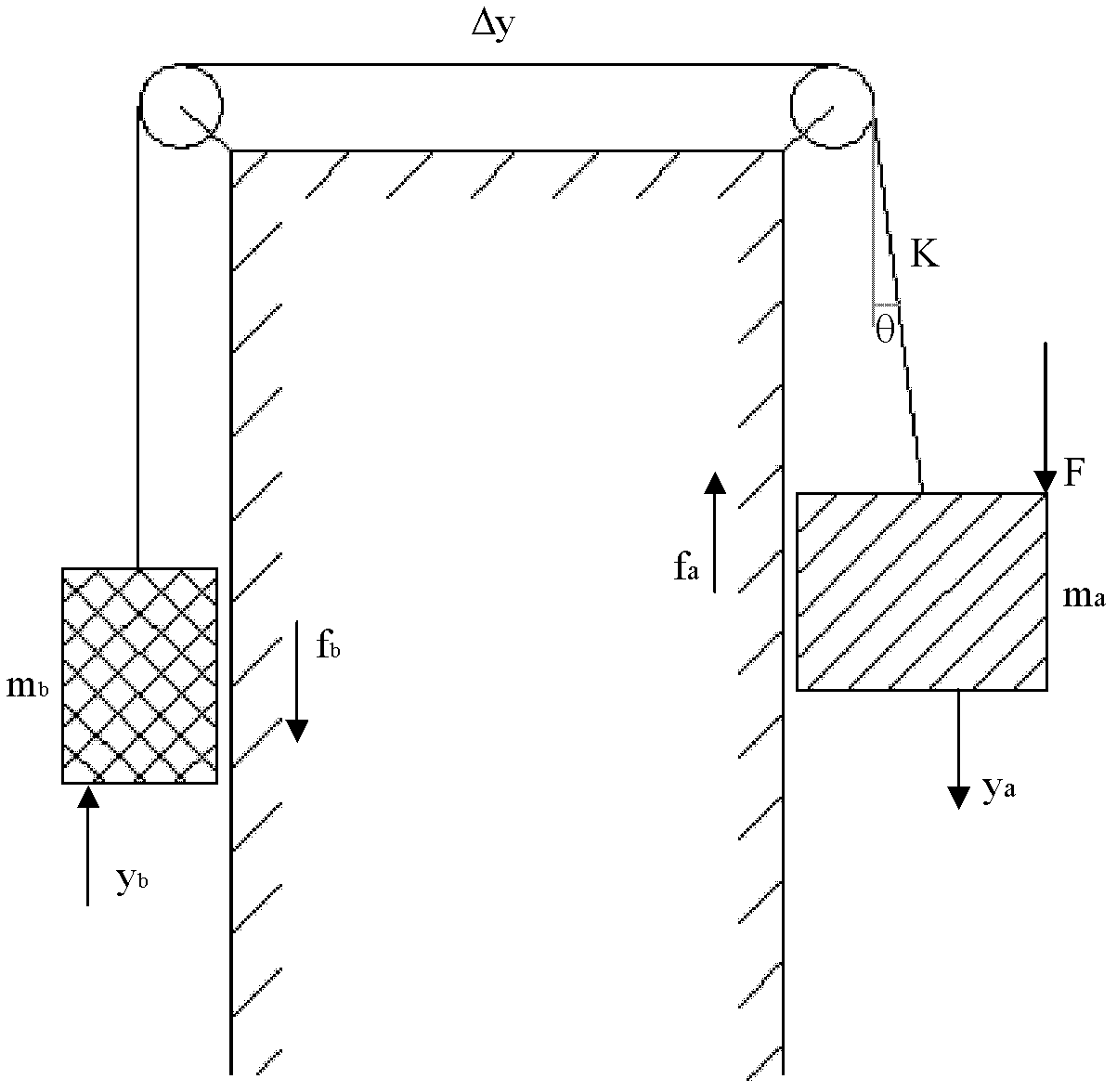

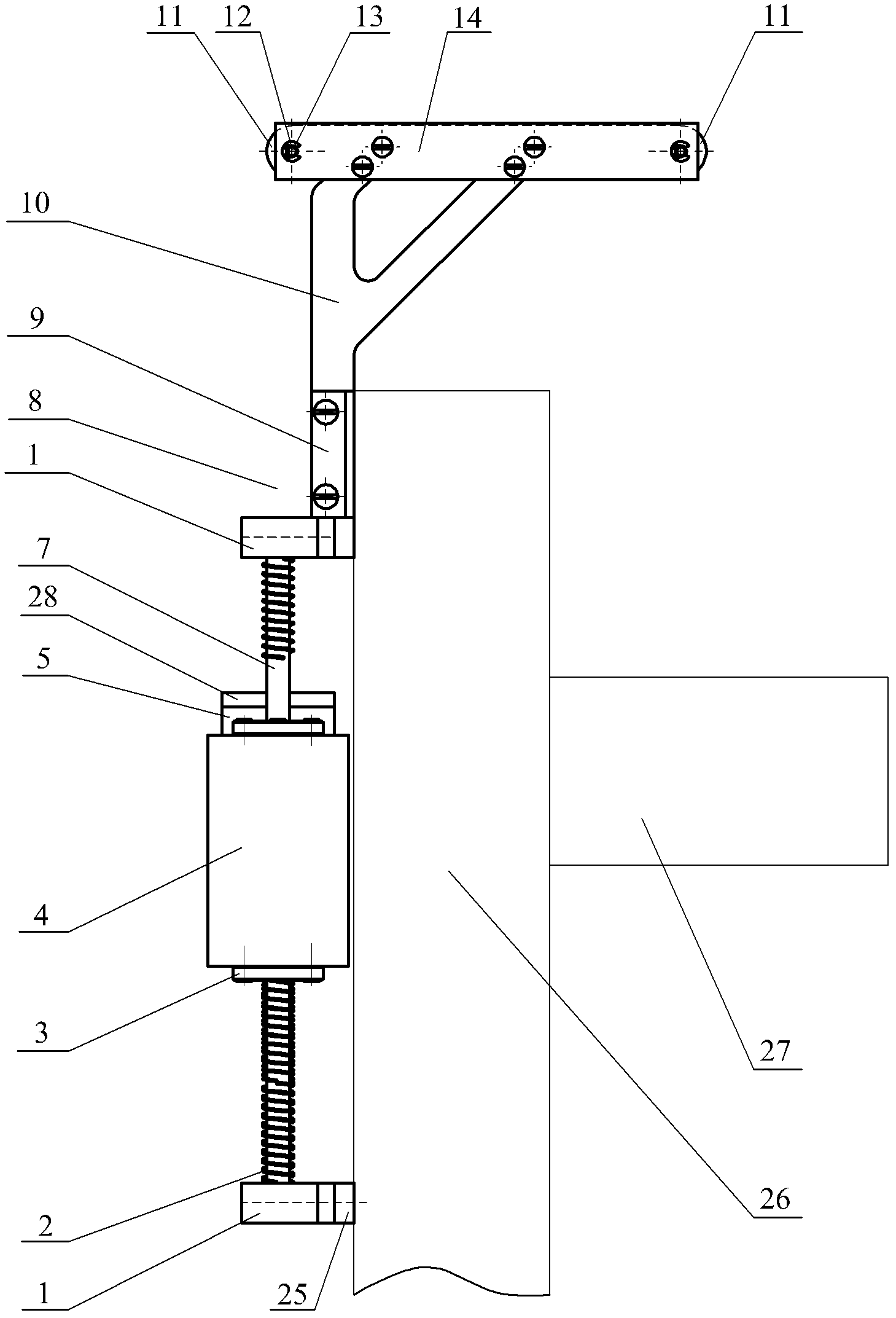

[0015] Specific implementation mode one: combine figure 1 and figure 2 Explain, the vertical axis counterweight device of the complex curved surface multi-axis linkage processing machine tool in this embodiment, the vertical axis counterweight device includes a counterweight unit and a guide wheel unit; , four optical shaft support seat gaskets 25, four optical axis support seats 1, six limit springs 2, four flange linear bearings 3 and two optical shafts 7; the counterweight 34 includes a large counterweight Block 4 and two small counterweights 5; the guide wheel unit includes a rope 8, a guide wheel support 10, two support shafts 13, a guide wheel support connector 9, two guide wheels 11, four shaft end stops Circle 12 and two guide wheel connecting plates 14;

[0016] The upper end surface of the large counterweight 4 is connected with two small counterweights 5, and the two small counterweights 5 are arranged symmetrically with respect to the vertical center line of the...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 and figure 2 Explain that the specific setting positions of the three limit springs 2 set on each optical axis 7 in this embodiment are as follows: the upper end surface of the optical axis supporting seat 1 connected to the upper end surface of each optical axis 7 to the top of the large counterweight 4 A limit spring 2 is arranged between the end surfaces, and two limit springs 2 are arranged between the optical axis supporting seat 1 connected to the lower end surface of each optical axis 7 and the lower end surface of the large counterweight 4 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 and figure 2 Illustrate, the upper end face of each small counterweight 5 of the present embodiment is connected with at least one adjusting washer 28 (connected by stud 21, the quality of these two small counterweights 5 can be changed, and can be here Add several adjusting shims 28 of different quality on the two small counterweights 5, according to the quality change of the linear motor or the ball screw working platform part and the load, it can play the role of comprehensively adjusting the quality of the whole counterweight part). Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com