Borax solution circulation pump

A solution circulation and borax technology, applied in the field of circulating pumps, can solve the problems of wear of dynamic and static rings, pipeline blockage, complex structure, etc., to prevent leakage and solve frequent damages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

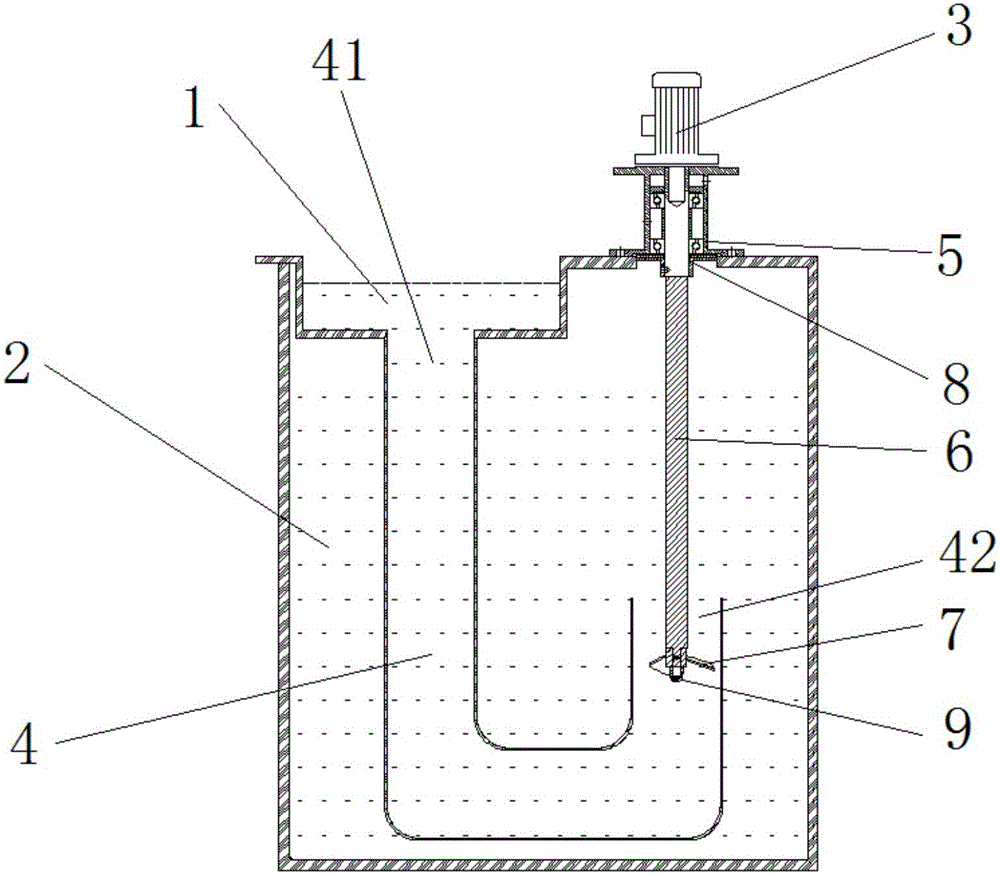

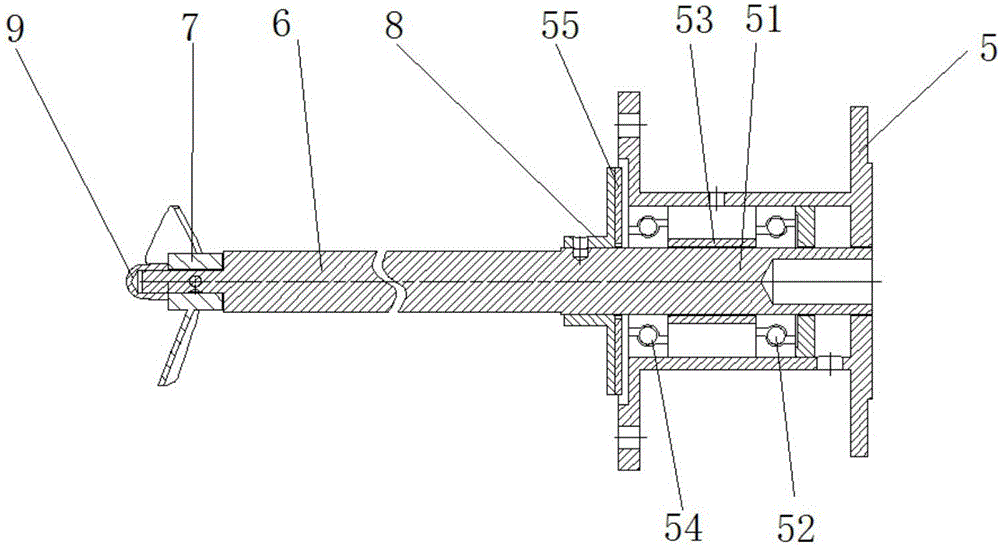

[0016] like Figure 1 ~ Figure 3 As shown: the borax solution circulating pump includes an upper tank 1, a lower tank 2, a motor 3, a U-shaped tube 4, a U-shaped tube A end 41, a U-shaped tube B end 42, a shaft coupling fixing frame 5, an installation hole 51, The first bearing 52, the bearing bushing 53, the second bearing 54, the outer cover of the bearing sleeve 55, the long axis 6, the impeller 7, the water throwing pan 8, the locking nut 9 and the like.

[0017] like figure 1 As shown, the borax solution circulating pump of the present invention comprises an upper tank 1 and a lower tank 2, the upper tank 1 is arranged on the upper left of the lower tank 1, the upper right of the lower tank 2 is installed with a motor 3, and the lower tank 1 is provided with a U-shaped Pipe 4, the two ends of U-shaped pipe 4 are respectively longer U-shaped pipe A end 41 and shorter U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com