Method for stirring welding pool in process of welding and electromagnetic pendulum device

A swing device and welding pool technology, applied in the field of welding processing, can solve the problems affecting the quality of the surfacing layer on the roll surface, affecting the metal structure of the surfacing layer, and the uneven hardness of the workpiece surface, achieving simple structure, low cost, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. Here, the exemplary embodiments and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

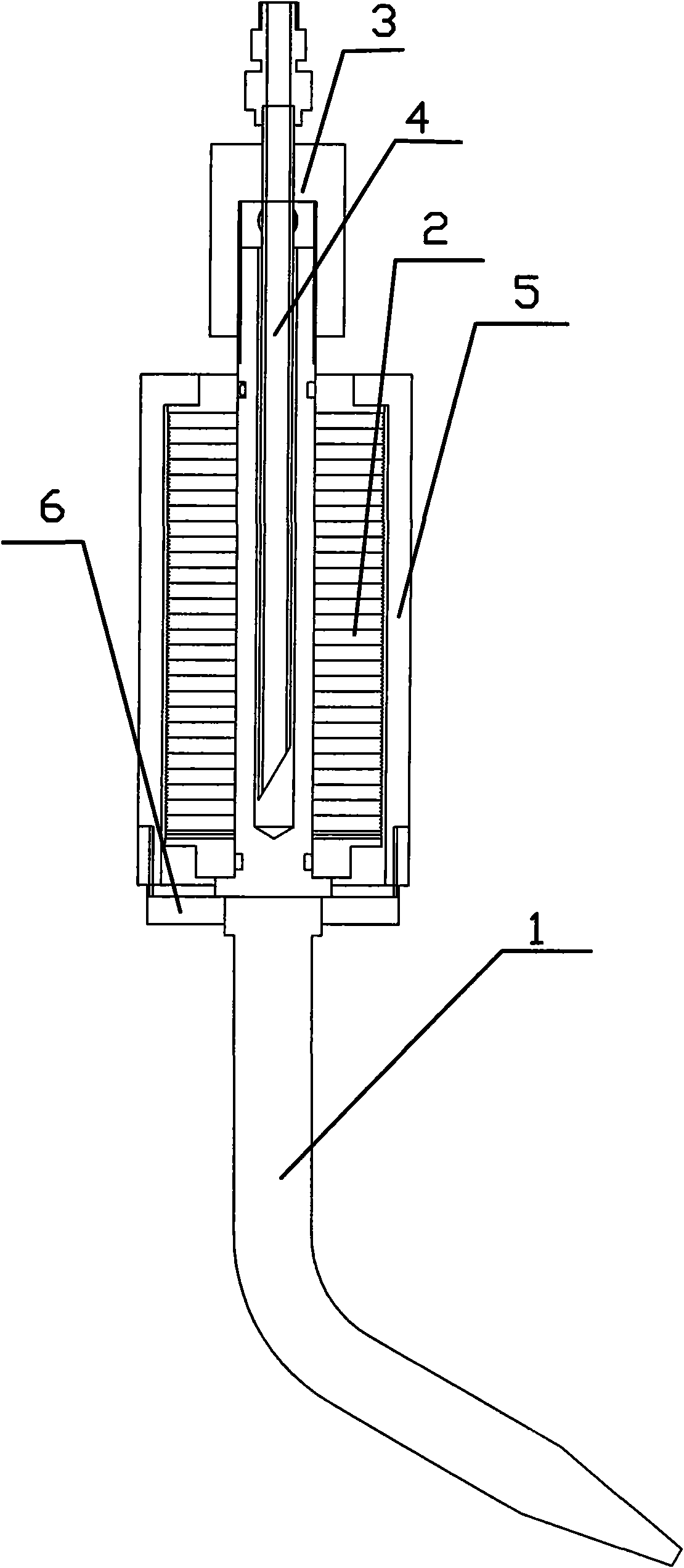

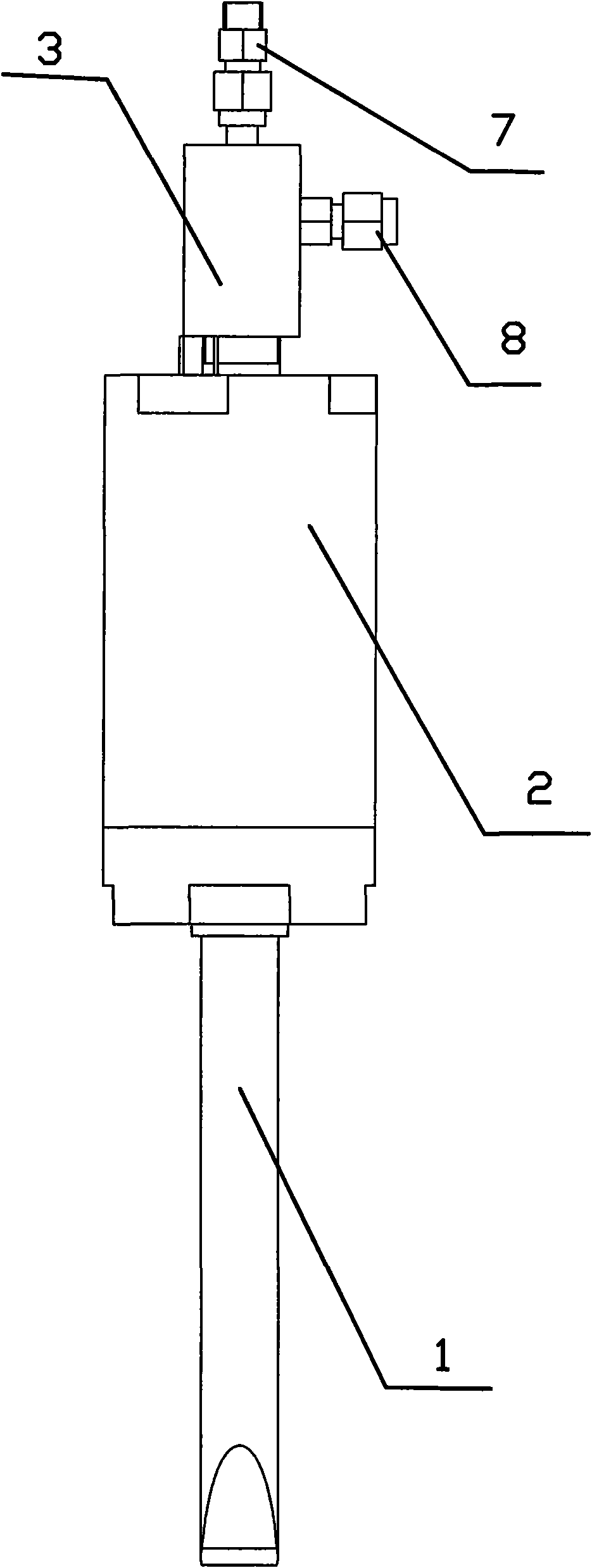

[0025] The method for stirring the welding molten pool in welding provided by this embodiment is as follows: an electromagnetic swing device is installed at the welding gun, the magnetic rod of the electromagnetic swing device is wound with an electromagnetic coil, and the end of the magnetic rod of the electromagnetic swing device is straight Butt welding gun muzzle position;

[0026] The welding wire is melted by the welding torch to form a welding molten pool. After the electromagnetic coil power supply of the electromagnetic swing device is turned on, a magnetic field in a certain direction is generated around the magnetic conductor. Under the action of the magnetic field, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com