Low-alloy composite roller and manufacturing method thereof

A technology of composite rolls and manufacturing methods, applied in metal rolling, metal rolling, rolls, etc., can solve the problems of high Ni content of precious metals, reduced hardness and wear resistance, and increased cost, so as to improve toughness and uniformity of hardness , uniform hardness, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

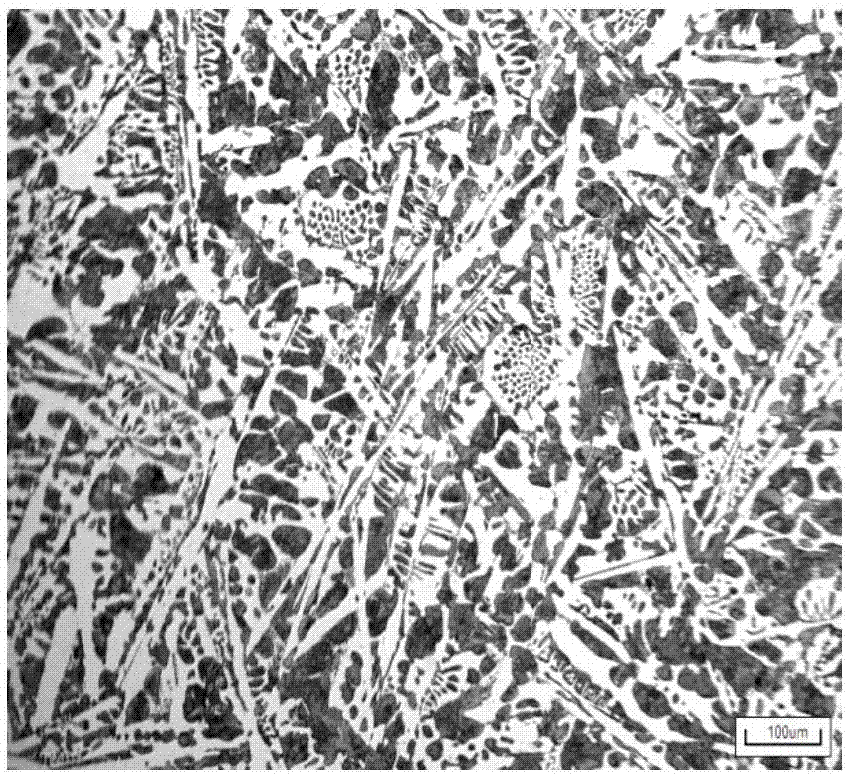

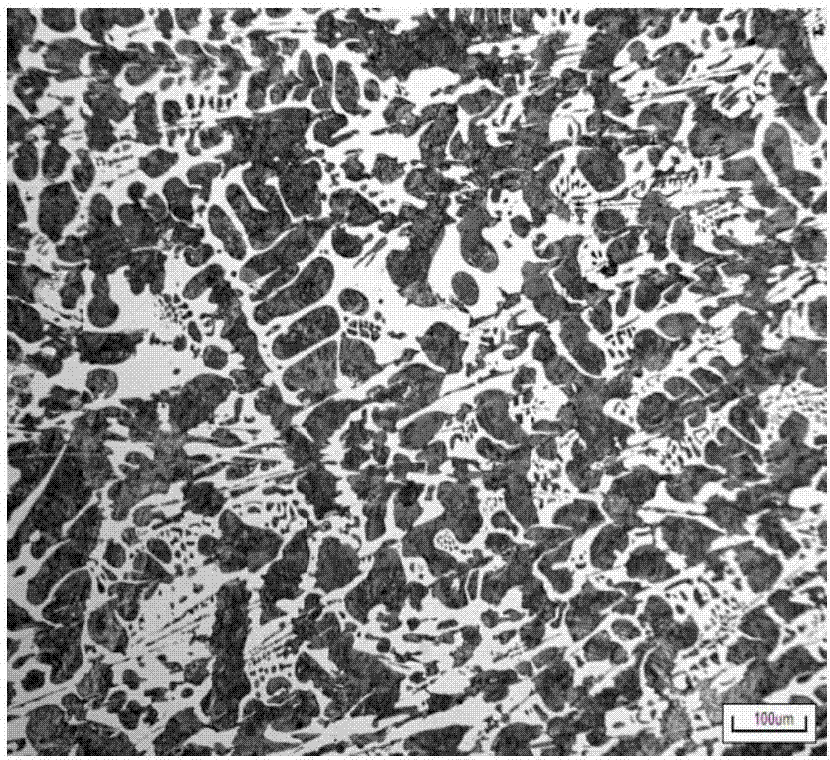

Image

Examples

Embodiment 1

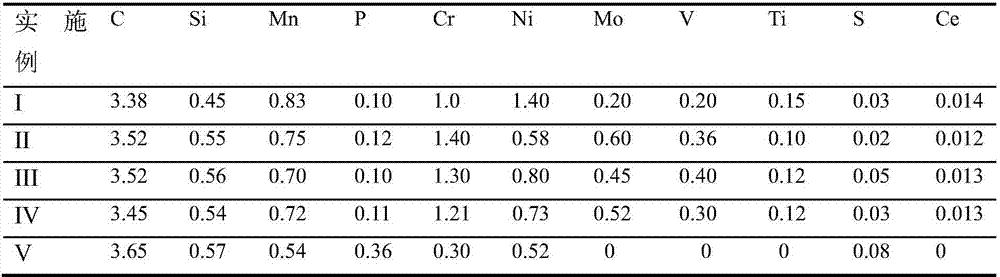

[0030] The low-alloy composite roll in the present invention can be used as a wear-resistant roll for food machinery, which includes an outer white cast iron layer and an inner gray cast iron layer; and in terms of mass percentage, the outer white cast iron layer includes: C 3.0~3.60%, Si0.50~1.0%, Mn 0.50~1.0%, Cr 0.50~1.50%, Ni 0.50~1.50%, Mo 0.20~1.0%, V0.10~0.80%, Ti 0.10~0.30%, Ce 0.10-0.30%, P<0.15%, S<0.10%, the rest is Fe; the inner gray cast iron layer includes: C 3.0-3.5%, Si 1.5-2.5%, Mn 0.5-1.0%, and the rest is …

[0031] Preferably, in terms of mass percentage, the outer white cast iron includes: C 3.38-3.52%, Si 0.54-0.56%, Mn 0.70-0.83%, Cr 1.00-1.40%, Ni 0.73-1.40%, Mo 0.20% ~0.60%, V 0.20~0.40%, Ti 0.10~0.15%, Ce 0.12~0.014%, P 0.10~0.12%, S 0.02~0.05%, and the rest is Fe.

[0032] Among them, the carbon (C) content of the outer white cast iron layer is 3.0 to 3.60%. C is the most important factor determining the hardness of carbides and matrix in low alloy...

Embodiment 2

[0058] The composition ratio of the outer white cast iron layer in this embodiment is shown in Table 1. The only difference from Embodiment 1 is that in step S2, the pouring temperature is 1450°C, and the speed of the pouring machine is 1000 rpm; In step S3, the pouring temperature is 1390°C; in step S5, the annealing temperature is 10 hours.

[0059] After testing, the surface Rockwell hardness of the composite roll obtained by the manufacturing method of this embodiment is 53.8-55.2HRC, and there is no cracking phenomenon.

Embodiment 3

[0061] The composition ratio of the outer white cast iron layer in this embodiment is shown in Table 1. The only difference from the above embodiment is that in step S2, the pouring temperature is 1450° C., and the pouring machine rotates at 1000 rpm; In step S3, the pouring temperature is 1380°C; in step S5, the annealing temperature is 8 hours.

[0062] After testing, the surface Rockwell hardness of the composite roll obtained by the manufacturing method of this embodiment is 53.5-55.5 HRC, and there is no cracking phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com