High-uniformity and high-polishing type plastic mould steel ZW636 and preparation method thereof

A plastic mold steel, ZW636 technology, applied in the field of steel forging and heat treatment, can solve the problems of increasing the production difficulty of plastic mold steel, and achieve the effects of improving comprehensive performance, reducing structure differences, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

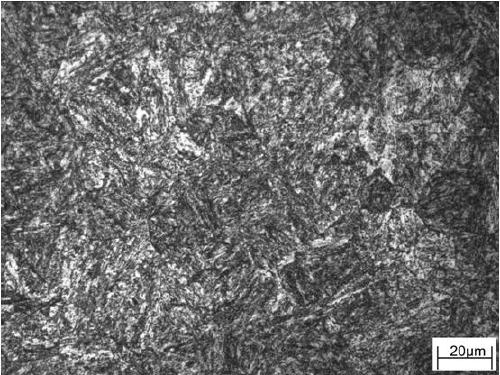

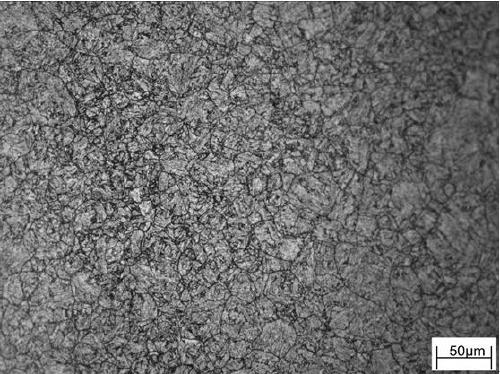

Image

Examples

Embodiment 1

[0033] The module size is 320*1310*4200mm.

[0034] Electroslag ingot shape: φ1100mm, ingot weight 19.6t.

[0035] The ingredients are as follows:

[0036] Example C Si mn P S Cr Ni Mo V 1 0.27 0.21 1.45 0.009 0.001 1.45 1.01 0.42 0.1

[0037] The specific implementation steps are as follows:

[0038] (I) Electrode blank softening annealing: according to the composition content in the above table, the electrode blank is obtained by smelting and continuous casting of die steel. The electrode blank is preheated at 350°C, heated to 740°C at full speed, and kept for 8h, at a rate of ≤40°C / h The furnace is cooled to 300°C and released.

[0039](II) Protective atmosphere electroslag remelting: after annealing, the electrode blanks are polished, and the polished electrode blanks are welded 7 pieces before smelting for 6 hours, and the slag used is baked at 700 ° C for 8 hours in advance When preparing the crystallizer tooling, it is necessa...

Embodiment 2

[0054] The module size is 460*1310*4200mm.

[0055] Electroslag ingot shape: φ1100mm, ingot weight 19.6t.

[0056] The ingredients are as follows,

[0057] Example C Si mn P S Cr Ni Mo Nb 2 0.27 0.20 1.47 0.010 0.001 1.46 1.02 0.48 0.1

[0058] The specific implementation steps are as follows:

[0059] (I) Electrode blank softening annealing: according to the composition content in the above table, the electrode blank is obtained by smelting and continuous casting of die steel. The electrode blank is preheated at 350°C, heated to 740°C at full speed, and kept for 8h, at a rate of ≤40°C / h The furnace is cooled to 300°C and released.

[0060] (II) Protective atmosphere electroslag remelting: after annealing, the electrode blanks are polished, and the polished electrode blanks are welded 7 pieces before smelting for 6 hours, and the slag used is baked at 700 ° C for 8 hours in advance When preparing the crystallizer tooling, it is nece...

Embodiment 3

[0075] The module size is 600*1400*2200mm.

[0076] Electroslag ingot shape: φ1100mm, ingot weight 19.6t.

[0077] The ingredients are as follows:

[0078] Example C Si mn P S Cr Ni Mo V 3 0.27 0.19 1.46 0.009 0.002 1.46 1.03 0.55 0.1

[0079] The specific implementation steps are as follows:

[0080] (1) Converter smelting: Calculate the ratio of raw materials according to the composition content in the above table as the final content of mold steel, add high-clean steel scrap and molten iron into the converter, blow oxygen for 13 minutes, and use high-strength supplementary blowing operation to ensure the carbon content at the end of the converter At the same time as reducing the oxygen content in the molten steel, the smelting end point temperature is 1630°C. After sampling and testing the carbon and phosphorus content, the steel is tapped. It is lime and refining slag) and alloyed, and then refining in LF furnace.

[0081] (2) LF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com