Hot processing technology method for bearing steel parts

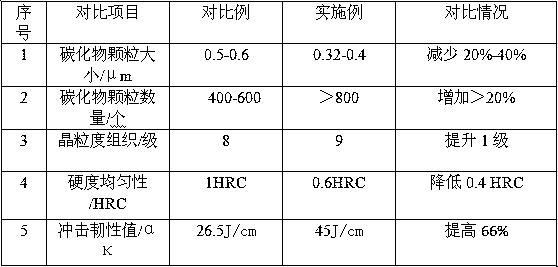

A process method and hot processing technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problems of difficulty in manufacturing and guaranteeing performance and quality, unable to meet the performance requirements, etc., and achieve uniform spheroid structure refinement and carbonization. The effect of particle reduction and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A thermal processing method for bearing steel parts, comprising the following steps:

[0033] Step 1. Billet forging

[0034] Put the billet into a medium frequency induction heating furnace and heat it to 1100°C for 10 minutes, then forge the billet on a ring rolling machine into a ring-shaped part of φ100×φ86×25mm, control the forging ratio to 1.8-2.8, and start the forging temperature not lower than 1050°C, the final forging temperature is higher than 950°C;

[0035] Step 2. Cooling after forging

[0036]Put the forged part into the cooling medium immediately after forging, and cool it to the surface temperature of the part at a cooling rate of 50 °C / s to 650 °C, so that the austenite in the part is transformed into fine pearlite particles; then the part is Take it out of the cooling medium, and let the part air cool to 400°C to eliminate the temperature difference between the inside and the surface of the part, and make the distribution of pearlite particles in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com