Method for reducing surface cracks of boron containing steel continuous casting sheet billet

A technology of surface cracking and continuous casting, applied in the field of iron and steel metallurgy, can solve the problems of irreparable, scrapped cast slabs, serrated cracks in steel plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

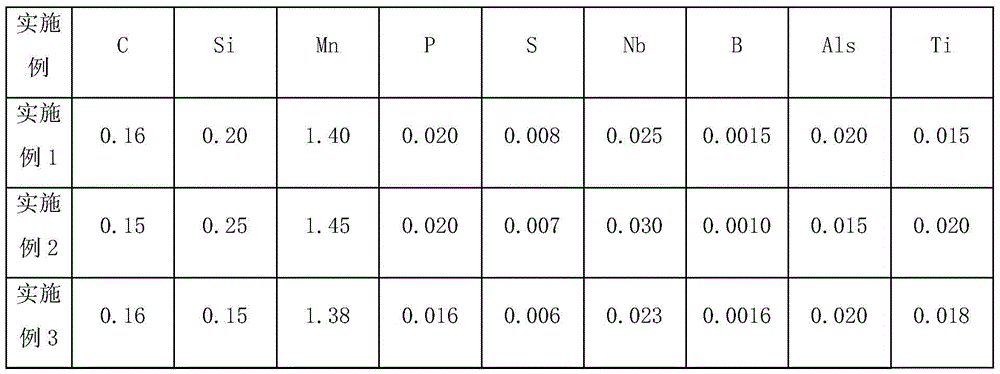

Embodiment 1

[0034]The continuous casting machine used is an ultra-low-head slab continuous casting machine. The metallurgical length of the casting machine is 17m, and the arc radius is R5.7 / 6.8 / 8.5 / 12 / 17 / 33—1500. It is composed of 7 segments, of which 3, The fourth section is the straightening section, and the annual production capacity of the casting machine is 900,000 tons / year. Prepare American Standard S355JR-B series boron-containing steel, its standard composition control (mass percentage) is: including 0.14%~0.18% C, 0.10%~0.30% Si, 1.32%~1.52% Mn, 0.025% or less P, 0.010% of S, 0.020% to 0.035% of Nb, 0.0008% to 0.0020% of B, 0.015% or more of Als, 0.008% to 0.022% of Ti, and the balance is Fe and unavoidable impurity elements.

[0035] 1) Molten steel smelting: After converter smelting, carry out LF refining, deoxidize until the oxygen content of molten steel is below 0.0050%, then add ferro-titanium and then ferroboron at the later stage of LF refining to control the compositio...

Embodiment 2

[0042] The continuous casting machine used is an ultra-low-head slab continuous casting machine. The metallurgical length of the casting machine is 17m, and the arc radius is R5.7 / 6.8 / 8.5 / 12 / 17 / 33—1500. It is composed of 7 segments, of which 3, The fourth section is the straightening section, and the annual production capacity of the casting machine is 900,000 tons / year. Prepare American Standard S355JR-B series boron-containing steel, its standard composition control (mass percentage) is: including 0.14%~0.18% C, 0.10%~0.30% Si, 1.32%~1.52% Mn, 0.025% or less P, 0.010% of S, 0.020% to 0.035% of Nb, 0.0008% to 0.0020% of B, 0.015% or more of Als, 0.008% to 0.022% of Ti, and the balance is Fe and unavoidable impurity elements.

[0043] 1) Molten steel smelting: After converter smelting, carry out LF refining, deoxidize until the oxygen content of molten steel is below 0.0050%, then add ferro-titanium and then ferroboron at the later stage of LF refining to control the compositi...

Embodiment 3

[0050] The continuous casting machine used is an ultra-low-head slab continuous casting machine. The metallurgical length of the casting machine is 17m, and the arc radius is R5.7 / 6.8 / 8.5 / 12 / 17 / 33—1500. It is composed of 7 segments, of which 3, The fourth section is the straightening section, and the annual production capacity of the casting machine is 900,000 tons / year. Prepare American Standard S355JR-B series boron-containing steel, its standard composition control (mass percentage) is: including 0.14%~0.18% C, 0.10%~0.30% Si, 1.32%~1.52% Mn, 0.025% or less P, 0.010% of S, 0.020% to 0.035% of Nb, 0.0008% to 0.0020% of B, 0.015% or more of Als, 0.008% to 0.022% of Ti, and the balance is Fe and unavoidable impurity elements.

[0051] 1) Molten steel smelting: After converter smelting, carry out LF refining, deoxidize until the oxygen content of molten steel is below 0.0050%, then add ferro-titanium and then ferroboron at the later stage of LF refining to control the compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com