Underwater dispersion-resistant porous concrete with large particle size and preparation method thereof

A technology of porous concrete and large particle size, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. Disturb the soil around the pile, etc., to achieve the effect of early strength improvement, strength improvement, single pile bearing capacity and composite foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1 prepares 40L of underwater anti-dispersion large particle size porous concrete

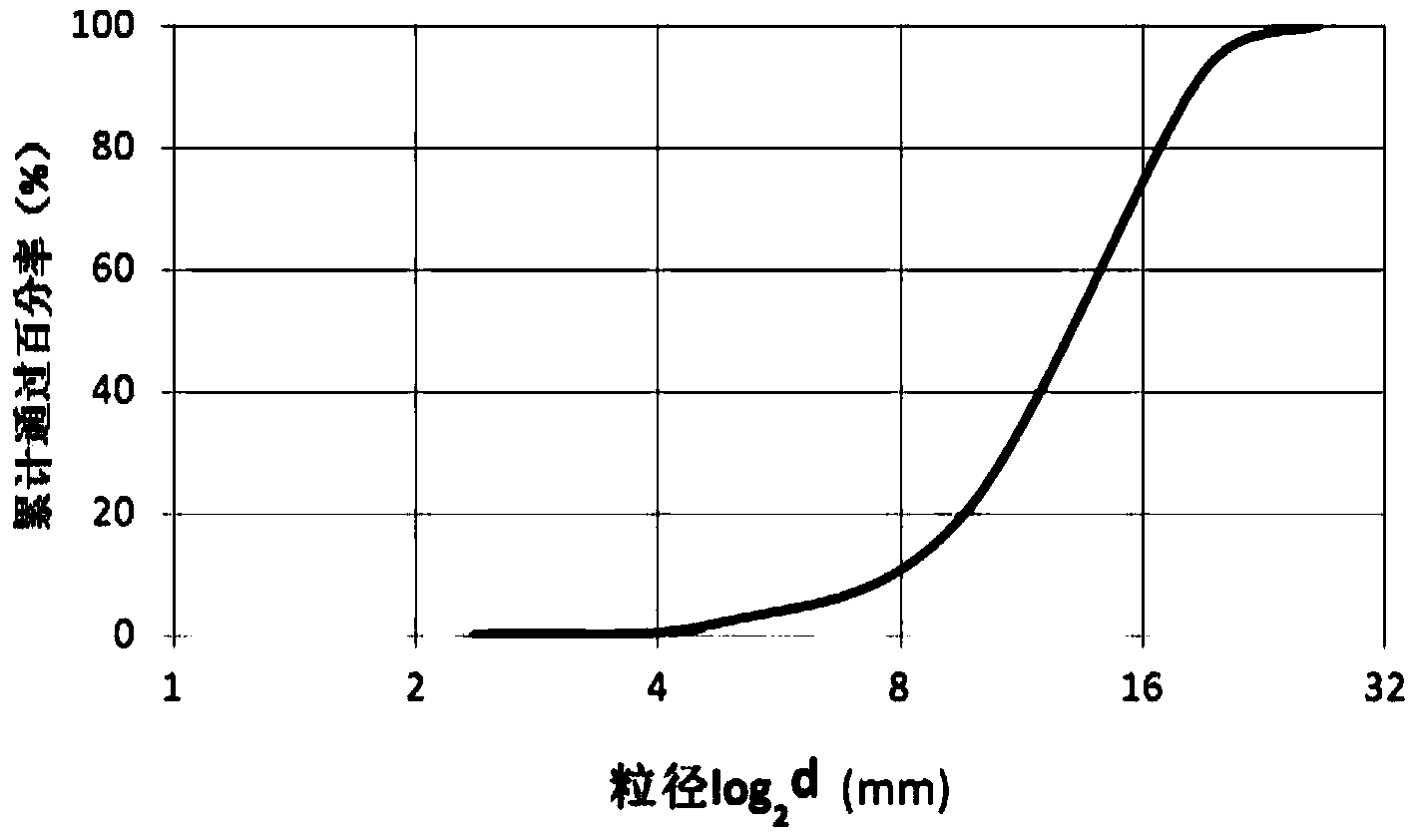

[0026] The preparation of underwater anti-dispersion large particle size porous concrete is composed of aggregate, cement, mineral admixture, water and thickener. According to mass ratio, (sum of cement and mineral admixture) / (aggregate)=0.23; water / (sum of cement and mineral admixture)=0.28. Described mineral admixture is micro-silica fume and nano-calcium carbonate; Micro-silica fume accounts for 5% of cement; Nano-calcium carbonate accounts for 0.5% of cement, and thickener accounts for cementitious material (cement and micro-silica powder and nano-carbonic acid 3.5% of the sum of calcium); the aggregate is crushed stone with a particle size of 5-20mm, see image 3 .

[0027] The preparation process is as follows: weigh 60.8kg of aggregate, 13.3kg of cement, 0.7kg of silica fume powder, 70g of nano-calcium carbonate, and 492g of thickener. Water: 3.92kg. Add microsilica fum...

example 2

[0029] Example 2 prepares 40L of underwater anti-dispersion large particle size porous concrete

[0030] The preparation of underwater anti-dispersion large particle size porous concrete is composed of aggregate, cement, mineral admixture, water and thickener. According to mass ratio, (sum of cement and mineral admixture) / (aggregate)=0.21; water / (sum of cement and mineral admixture)=0.28. Described mineral admixture is micro-silica fume and nano-calcium carbonate; Micro-silica fume accounts for 5% of cement; Nano-calcium carbonate accounts for 0.5% of cement, and thickener accounts for cementitious material (cement and micro-silica powder and nano-carbonic acid 3.5% of the sum of calcium); the aggregate is crushed stone with a particle size of 5-20mm, see image 3 .

[0031] The preparation process is as follows: weigh 60.8kg of aggregate, 12.16kg of cement, 0.64kg of silica fume powder, 64g of nano-calcium carbonate, and 448g of thickener. Water: 3.584kg. Add microsilica ...

example 3

[0032] Example 3 prepares 40L underwater anti-dispersion large particle size porous concrete

[0033] The preparation of underwater anti-dispersion large particle size porous concrete is composed of aggregate, cement, mineral admixture, water and thickener. According to mass ratio, (sum of cement and mineral admixture) / (aggregate)=0.19; water / (sum of cement and mineral admixture)=0.28. Described mineral admixture is micro-silica fume and nano-calcium carbonate; Micro-silica fume accounts for 5% of cement; Nano-calcium carbonate accounts for 0.5% of cement, and thickener accounts for cementitious material (cement and micro-silica powder and nano-carbonic acid 3.5% of the sum of calcium); the aggregate is crushed stone with a particle size of 5-20mm, see image 3 .

[0034]The preparation process is as follows: weigh 60.8kg of aggregate, 12.16kg of cement, 0.64kg of silica fume powder, 64g of nano-calcium carbonate, and 448g of thickener. Water: 3.584kg. Add microsilica fume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com