High-strength hot-dip galvanized steel sheet and process for producing the same

A technology of hot-dip galvanized steel sheet and manufacturing method, which can be applied to manufacturing tools, hot-dip galvanizing process, chemical instruments and methods, etc., and can solve the problems of poor stamping formability and poor appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] The present invention is further illustrated below by way of examples.

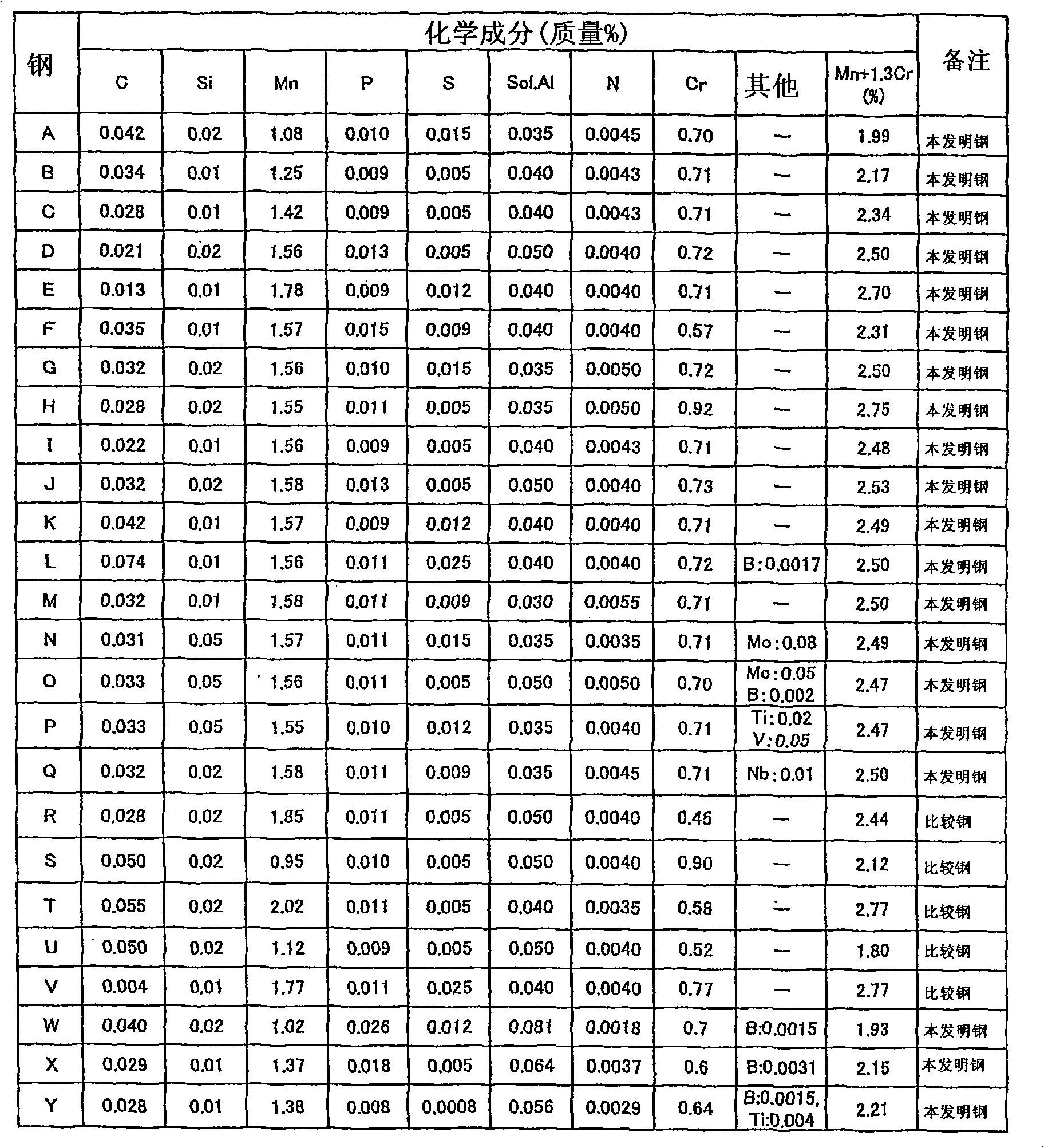

[0099] Steels having the chemical components of steels A to Y shown in Table 1 were melted by vacuum melting to produce billets. These billets were heated to 1200° C., hot rolled at a finishing temperature of 850° C., cooled, and then coiled at 600° C. to manufacture hot-rolled steel sheets with a thickness of 2.5 mm. The obtained hot-rolled steel sheet was pickled, then cold-rolled at a rolling reduction of 70%, to obtain a cold-rolled steel sheet having a thickness of 0.75 mm.

[0100] Table 1

[0101]

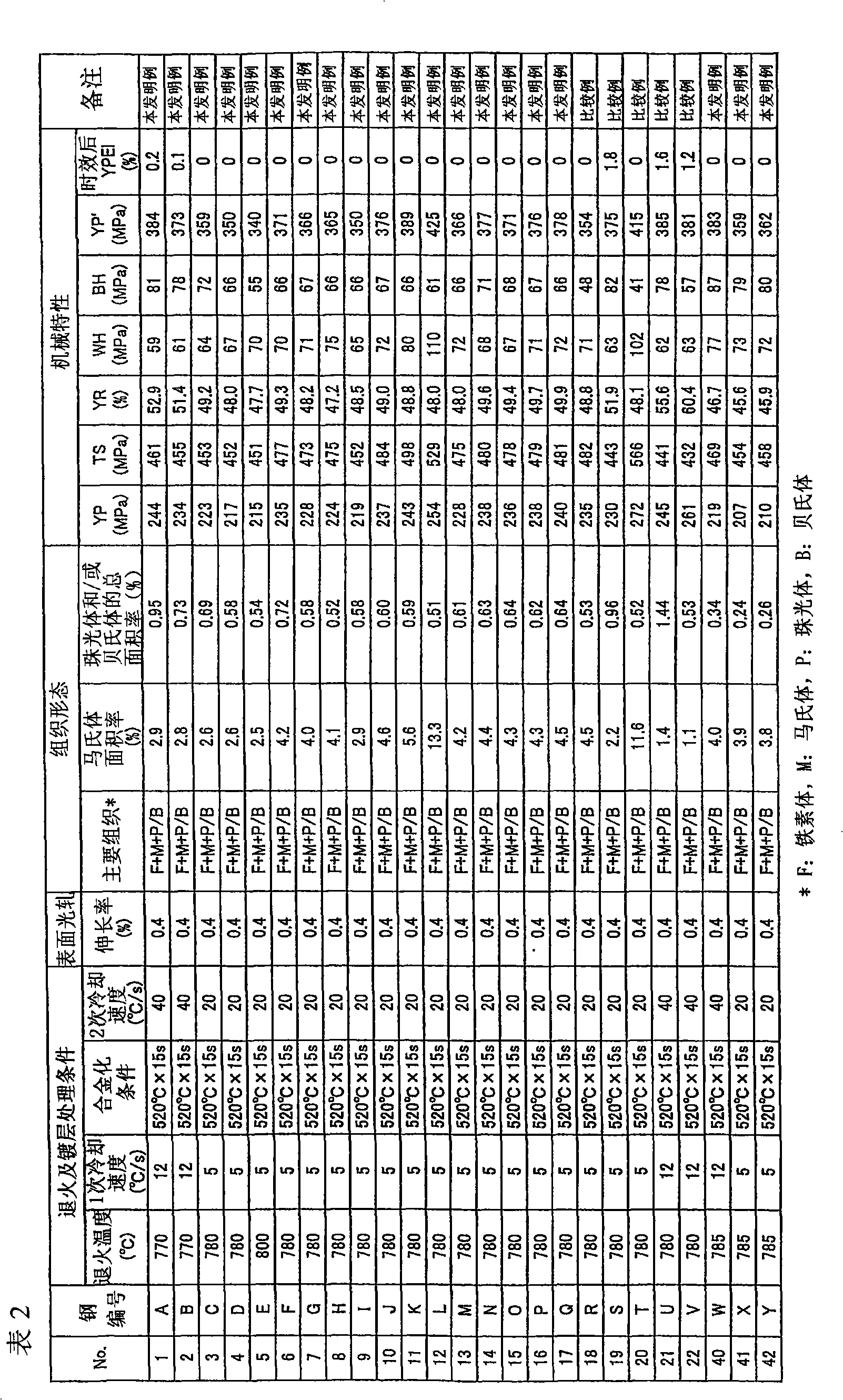

[0102] Next, the sample cut out from the cold-rolled steel sheet obtained above was held in an infrared thermography furnace (infrared image furnace) at the annealing temperature shown in Table 2 for 60 seconds, and then carried out under the conditions shown in Table 2. Secondary cooling, after hot-dip galvanizing (bath temperature: 460°C), alloying treatment (520°C×15s), secondary cooling ...

Embodiment 2

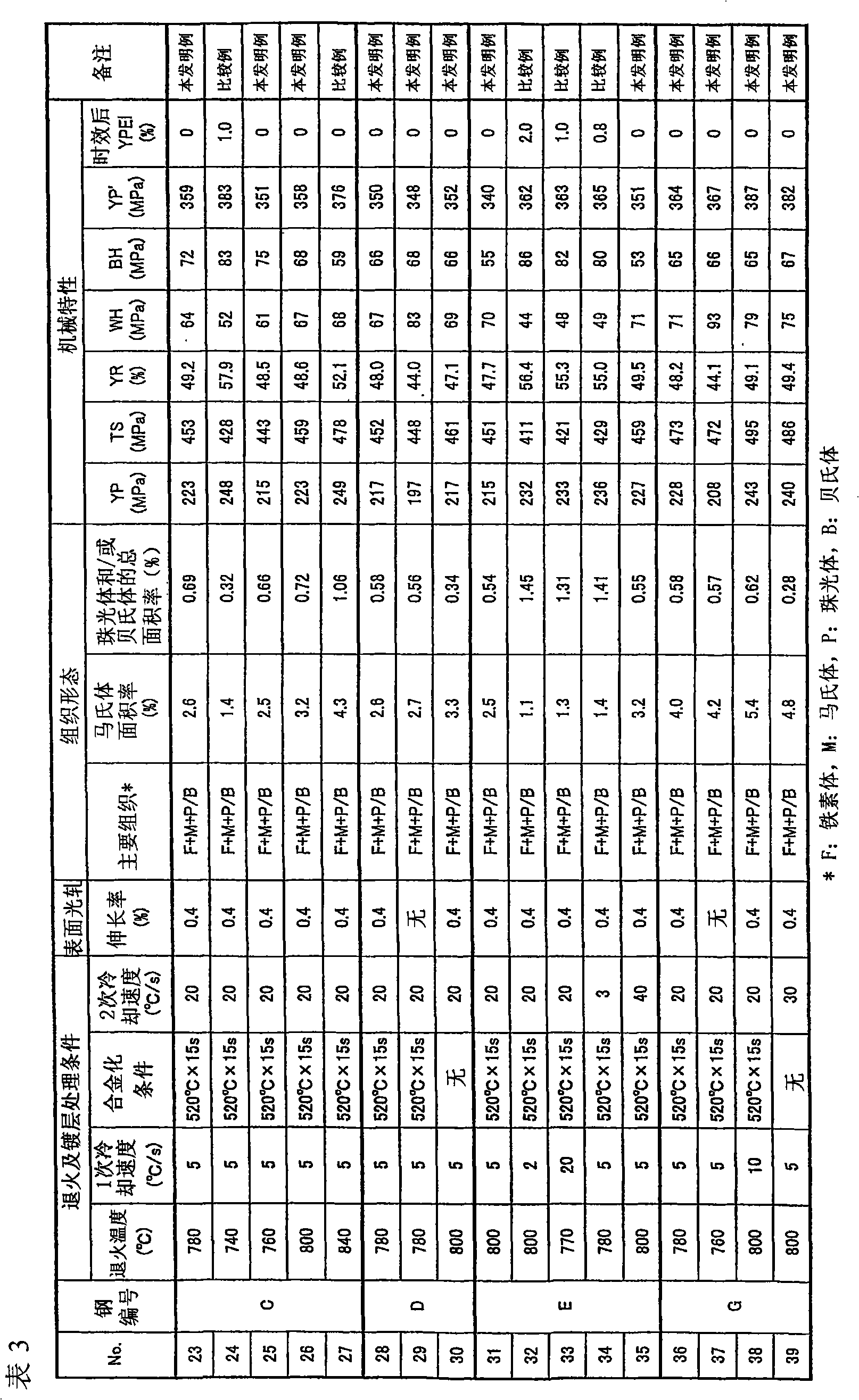

[0115] The steel with the chemical composition of steel C, D, E, G shown in Table 1 is smelted by vacuum smelting, hot rolling, pickling, cold rolling are implemented under the same conditions as in Example 1, as shown in Table 3 After holding at the annealing temperature for 60 seconds, perform primary cooling under the conditions shown in Table 3, perform hot-dip galvanizing treatment (plating bath temperature: 460°C), perform alloying treatment, and perform secondary cooling until 150°C Below the temperature, and implement surface pass rolling.

[0116] For the hot-dip galvanized steel sheet obtained above, samples were taken, and the area ratio of the martensite phase, the total area ratio of the pearlite phase and / or bainite phase were measured by the same method as in Example 1, and the tensile properties were measured. , work hardening (WH), sinter hardening (BH) and YPE1 after accelerated aging test.

[0117] The obtained results are shown in Table 3 together with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com