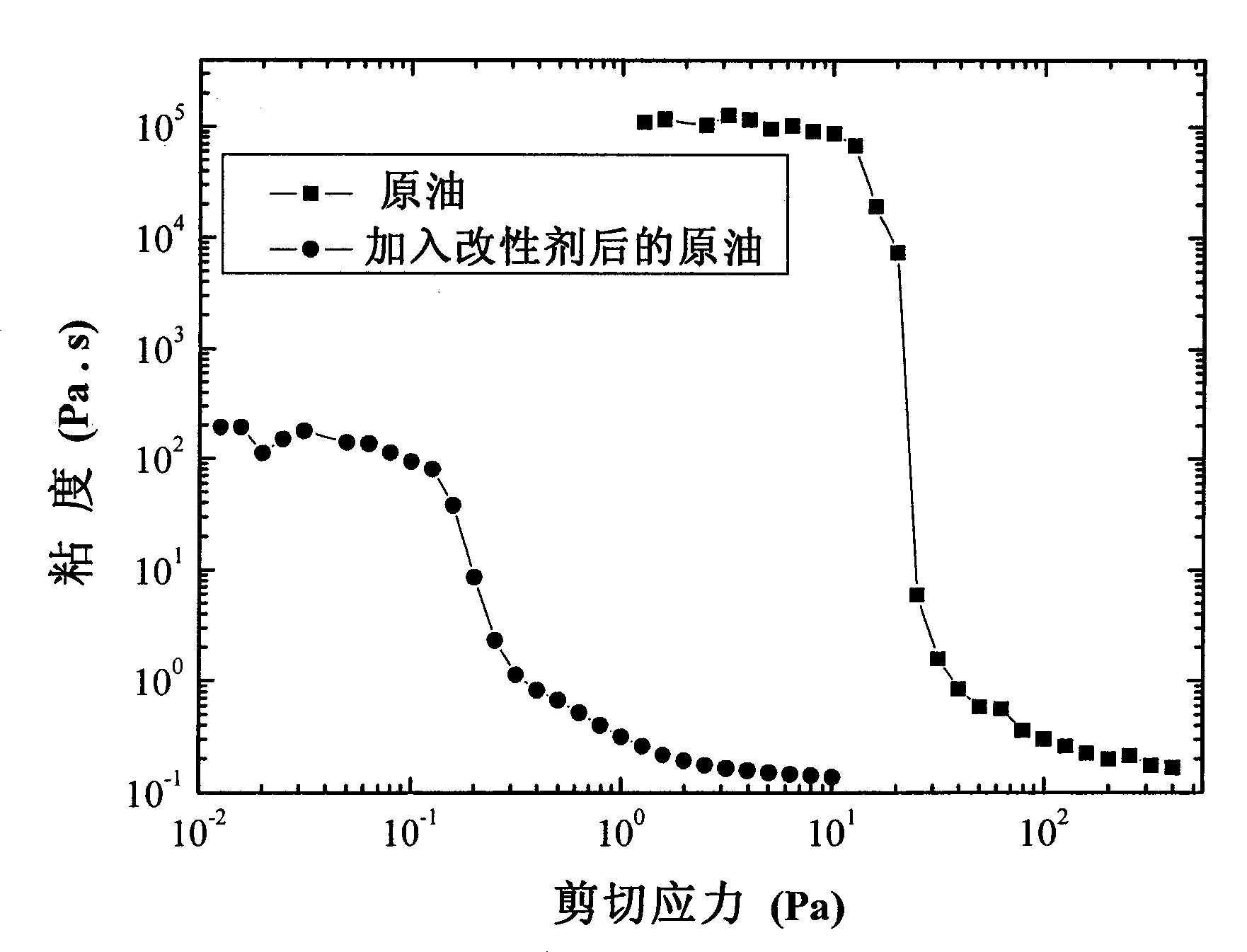

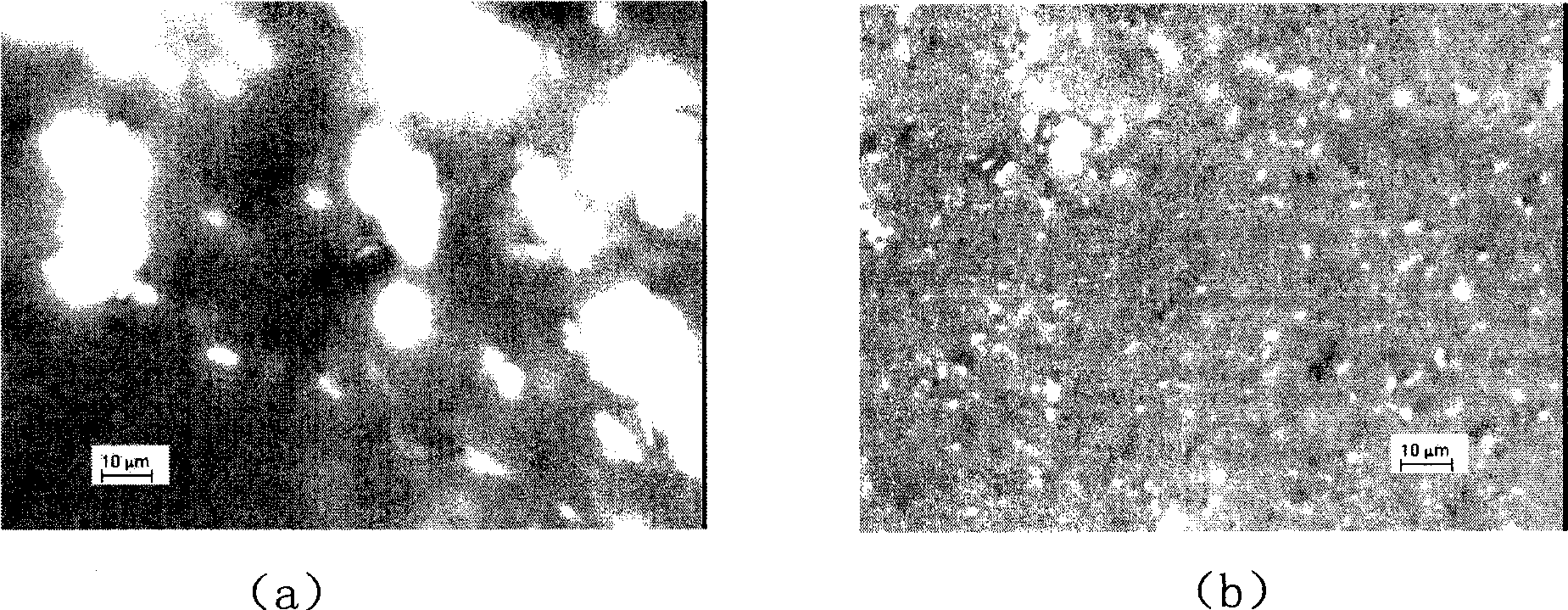

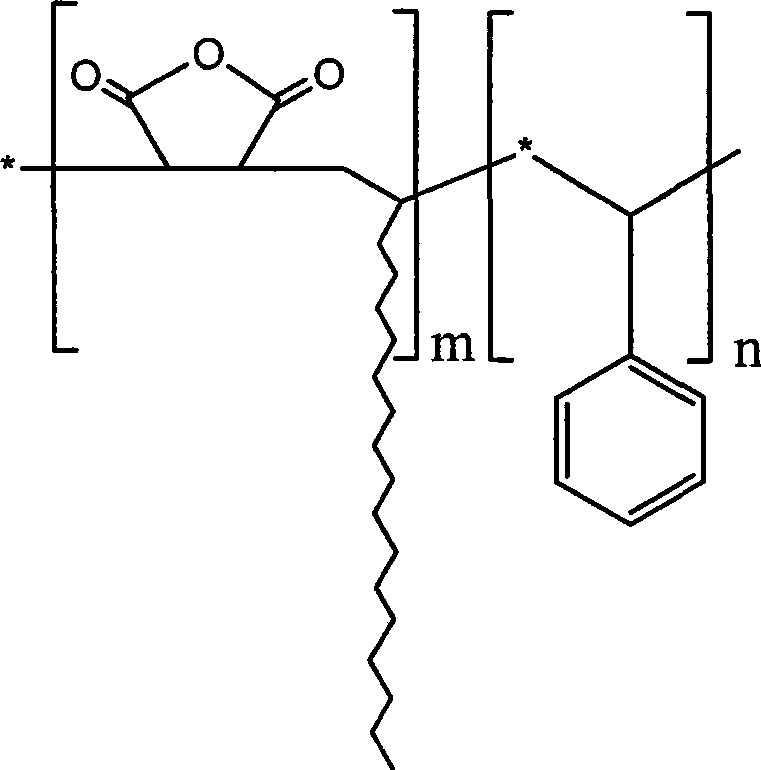

Three-element comb type copolymer, preparation method and application thereof

A comb-type copolymer and terpolymer technology, applied in the field of polymers and their preparation, can solve the problems of poor generality of pour point depressants and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of Ternary Comb Copolymer by Free Radical Solution Polymerization

[0025] Put 50ml of o-xylene, 5.96g of maleic anhydride, 21.56g of octadecene and 0.25g of benzoyl peroxide into a 250ml three-necked flask. Pump nitrogen gas 3 to 5 times, after fully dissolving, react at 110°C for 1.5 hours. After the temperature dropped to 75°C, 3.12g of styrene, 0.03g of benzoyl peroxide and 15ml of o-xylene were slowly dropped into the reaction system, and the reaction was continued at 75°C for 8 hours to obtain a terpolymer. Finally, 14.84 g of dodecylamine was added and reacted at 110° C. for 15 hours to complete the amination reaction, and finally a ternary comb copolymer was obtained.

Embodiment 2

[0026] Example 2 Preparation of Ternary Comb Copolymer by Free Radical Solution Polymerization

[0027] Put 50ml o-xylene, 5.96g maleic anhydride, 19.60g tetradecene and 0.20g benzoyl peroxide into a 250ml three-necked flask. Pump nitrogen 3 to 5 times, fully dissolve, and react at 120°C for 1 hour. After the temperature dropped to 85°C, 4.16g of styrene, 0.02g of benzoyl peroxide and 15ml of o-xylene were slowly dropped into the reaction system, and the reaction was continued at 85°C for 6 hours to obtain a terpolymer. Finally, 21.56 g of octadecylamine was added and reacted at 120° C. for 8 hours to complete the amination reaction, and finally a ternary comb copolymer was obtained.

Embodiment 3

[0028] Example 3 Preparation of Ternary Comb Copolymer by Free Radical Solution Polymerization

[0029] Put 50ml o-xylene, 5.96g maleic anhydride, 11.76 dodecene and 0.25g benzoyl peroxide into a 250ml three-neck flask. Pump nitrogen 3 to 5 times, fully dissolve, and react at 100°C for 2 hours. After the temperature dropped to 75°C, 4.16g of styrene, 0.02g of benzoyl peroxide and 15ml of o-xylene were slowly dropped into the reaction system, and the reaction was continued at 75°C for 8 hours to obtain a terpolymer. Finally, 26.57 g of hexadecylamine was added, and the amination reaction was completed at 100° C. for 24 hours to obtain a ternary comb copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com