The Second Radial Inner Ring Forming Process of the Inner Wall of Thin-walled Tube

A forming process and technology of thin-walled tubes, applied in the direction of manufacturing tools, metal processing equipment, applications, etc., can solve the problems that the thin-walled tubes with built-in two radial inner rings cannot be formed by upsetting and extruding, and achieve compact structure and structure The effect of high strength and high material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

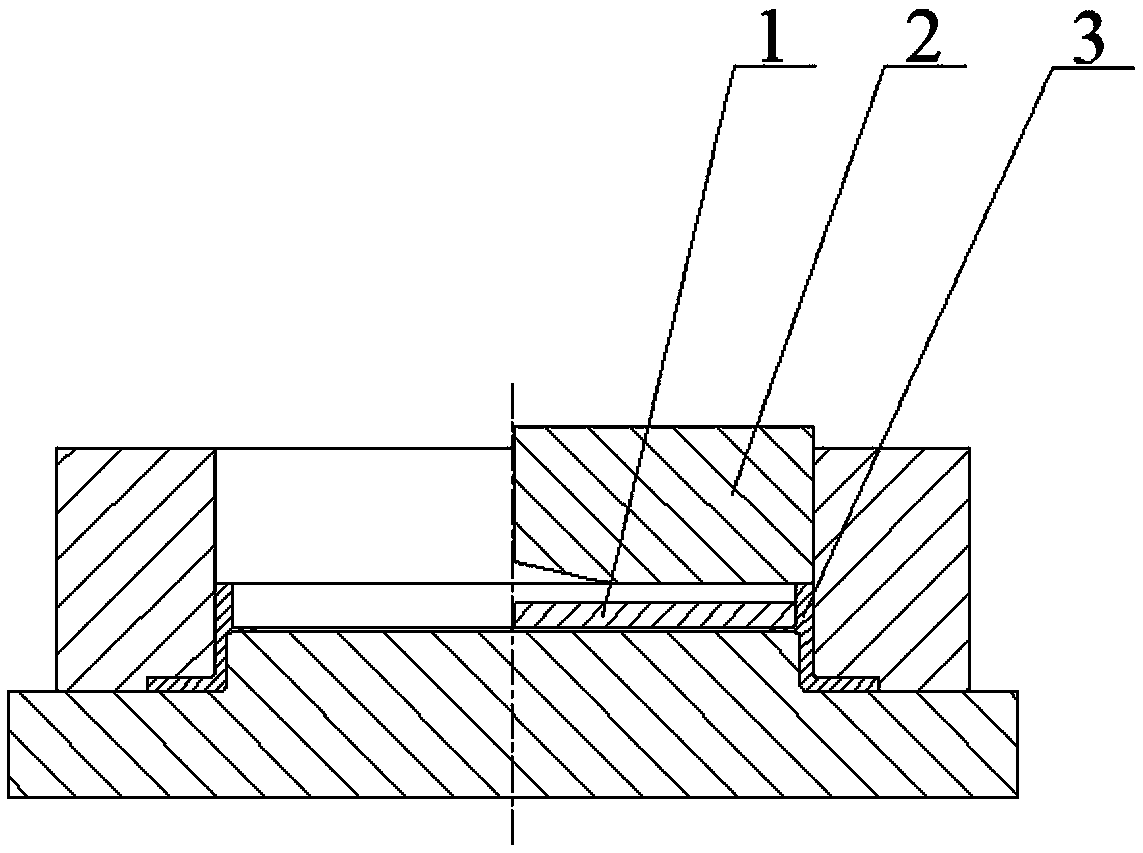

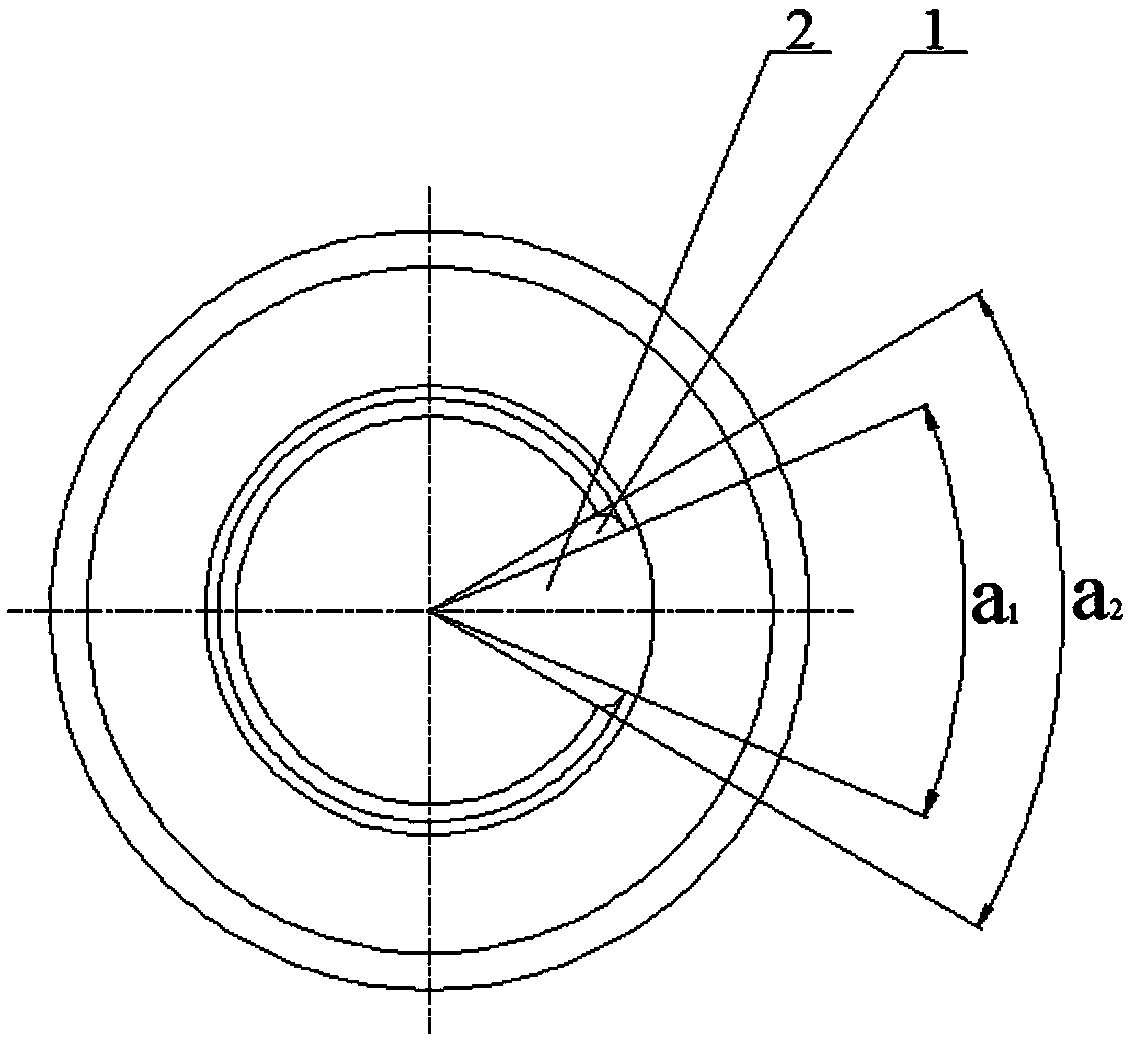

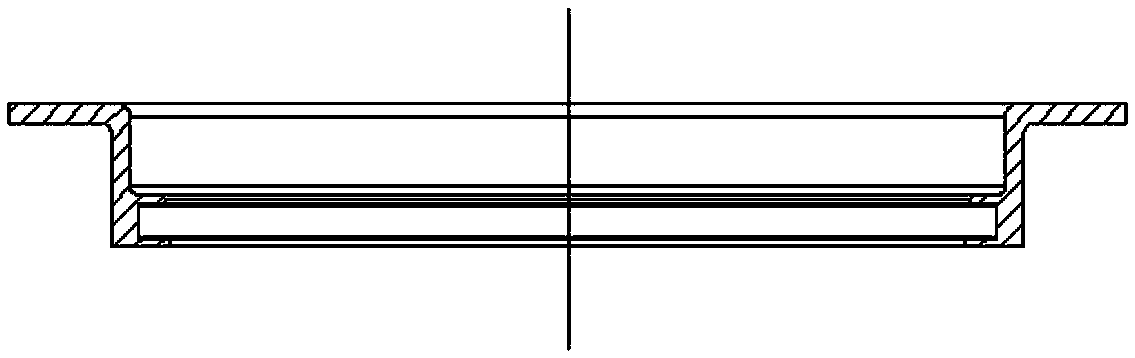

[0024] The second radial inner ring forming process on the inner wall of the thin-walled tube is a process for making the second radial inner ring on the basis of the forming of the cylindrical blank and the first radial inner ring forming on the inner wall of the thin-walled tube 3 . The cylindrical blank such as Figure 4 As shown, the semi-finished product of the thin-walled tube 3 with the first radial inner ring built in is as Figure 5 As shown, the above-mentioned two forming processes all belong to conventional processes, not the research content of the present invention, but only the previous process of the present invention. The technical problem to be solved in the present invention is to adopt the upsetting extrusion process to realize image 3 In the second radial inner ring forming process shown, the matching process ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com