Jacket-welded short CV joint coupling

A welding type and coupling technology, which is applied in the field of mechanical parts manufacturing, can solve problems such as low process productivity and material utilization rate, unfavorable production organization of spare parts in stock, and limited scope of application, so as to facilitate design and selection, shorten machine The effect of processing cycle and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

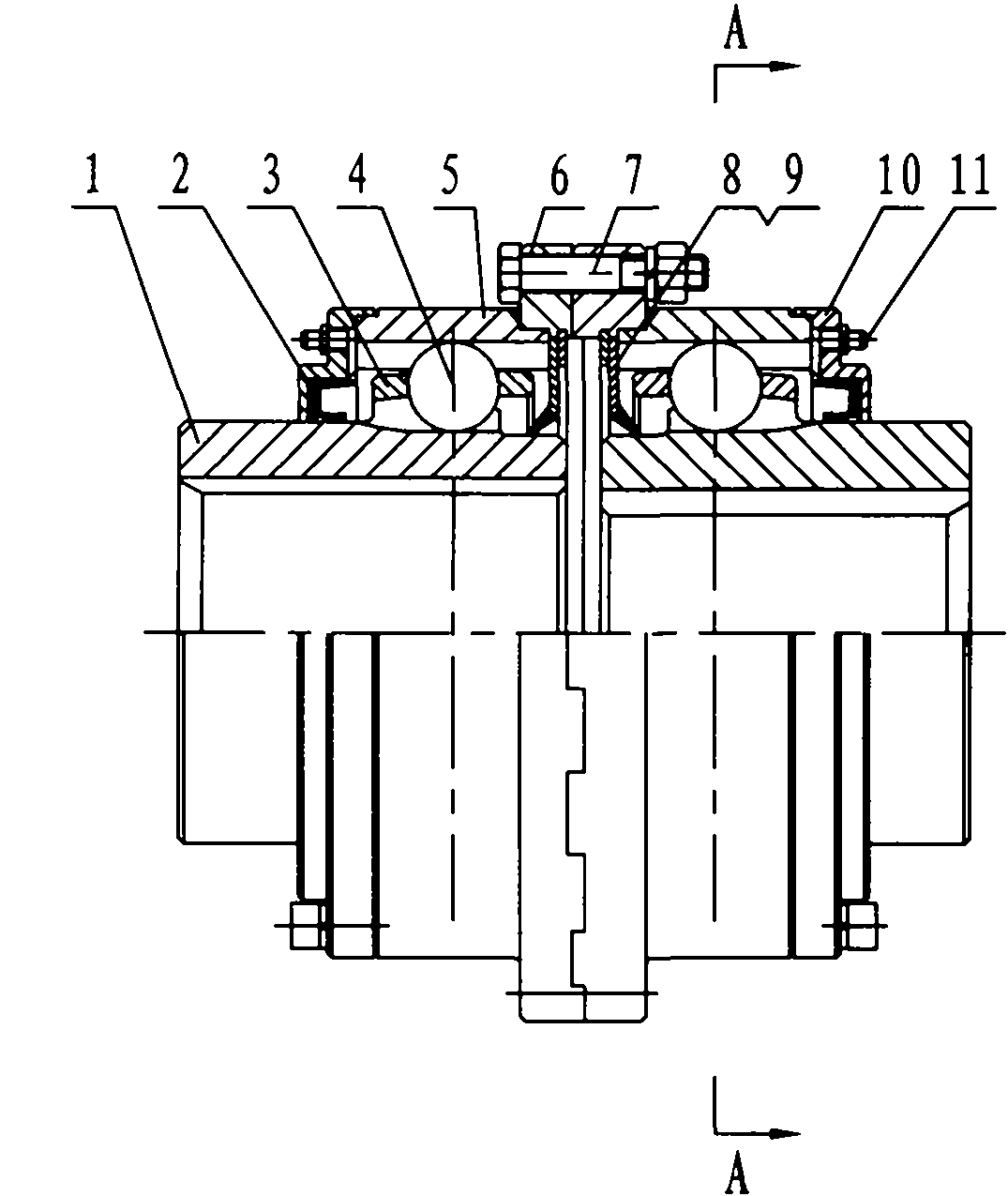

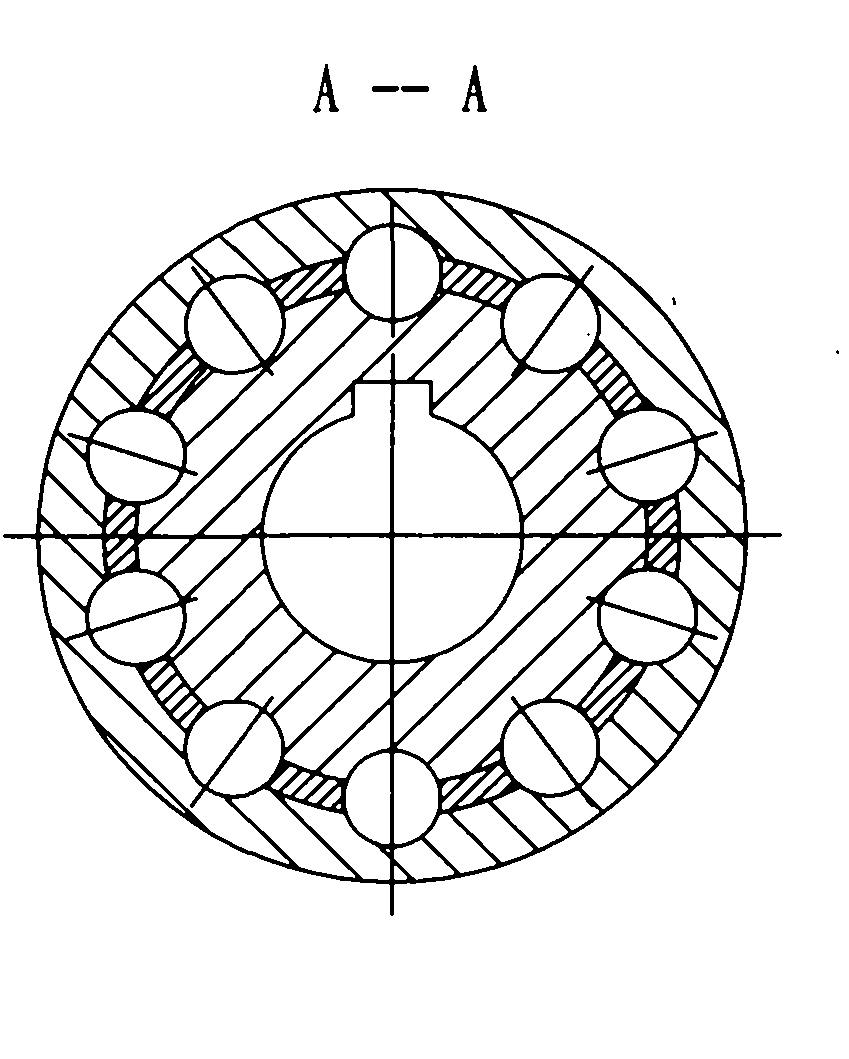

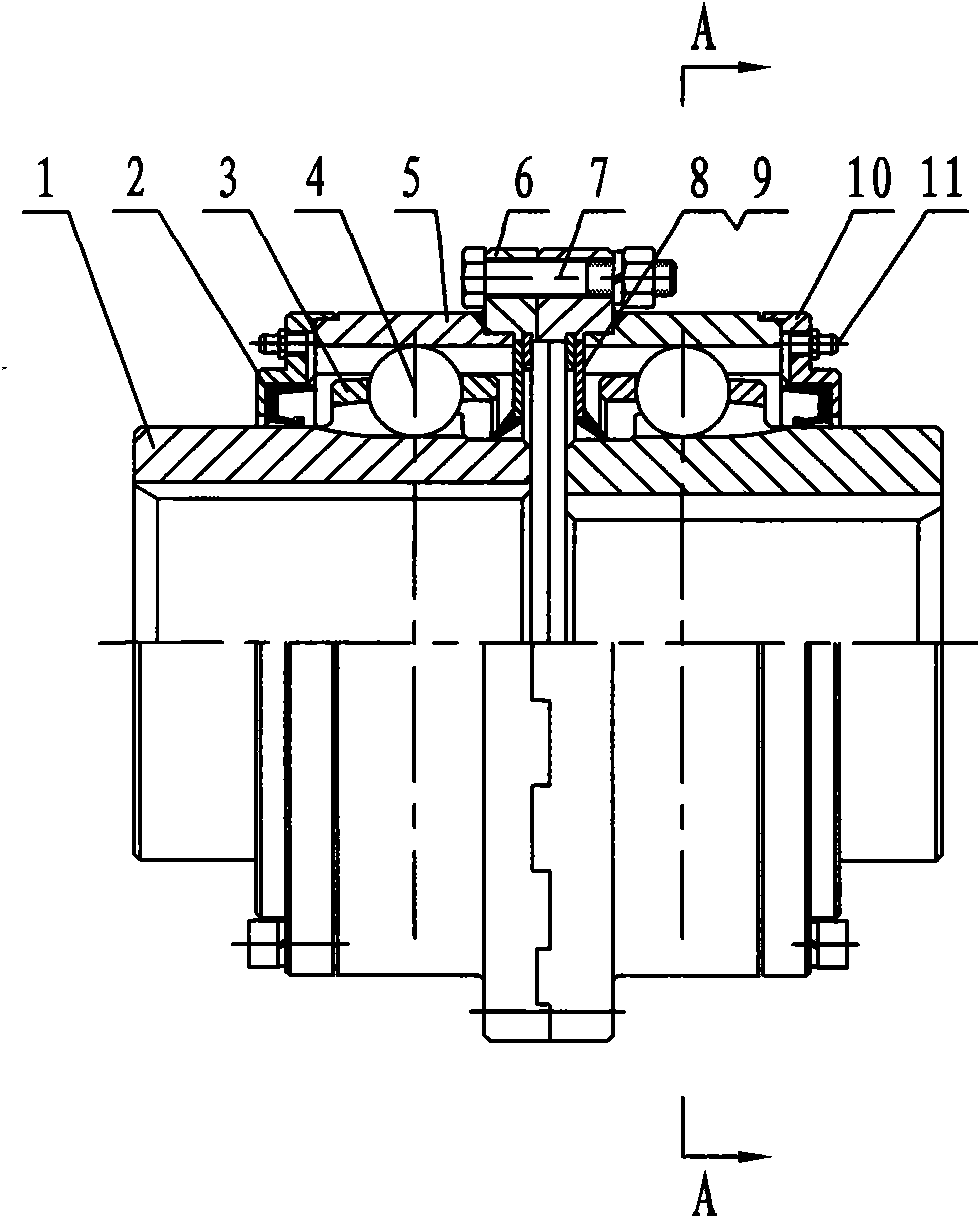

[0011] Such as figure 1 , figure 2 As shown, the present invention is composed of an inner sleeve 1, an oil seal 2, a cage 3, a steel ball 4, an outer sleeve 5, an end tooth plate 6, a bolt 7, a sealing baffle 8, a retaining ring 9 for a hole, a gland 10, and an oil nozzle 11. ; The two inner sleeves 1 have spline through holes or inner holes with key grooves to cooperate with the corresponding shaft extensions, and the outer diameter of the inner sleeve 1 has a spherical ring boss, which is matched with the inner spherical surface of the cage 3. Two groups of steel balls 4 are installed between the inner sleeve 1 and the outer sleeve 5, and the specific number of the steel balls 4 is determined by the required transmission capacity and internal geometric dimensions; Evenly distributed on the circumference, the cross section is an elliptical or circular straight channel, and the torque is transmitted through the channel of the inner sleeve 1, the steel ball, and the channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com