Welding gun cleaning device

A welding gun and gun cleaning technology, which is applied to auxiliary devices, welding equipment, cleaning torches, etc., can solve the problems of affecting the stability of the arc in the welding gun.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

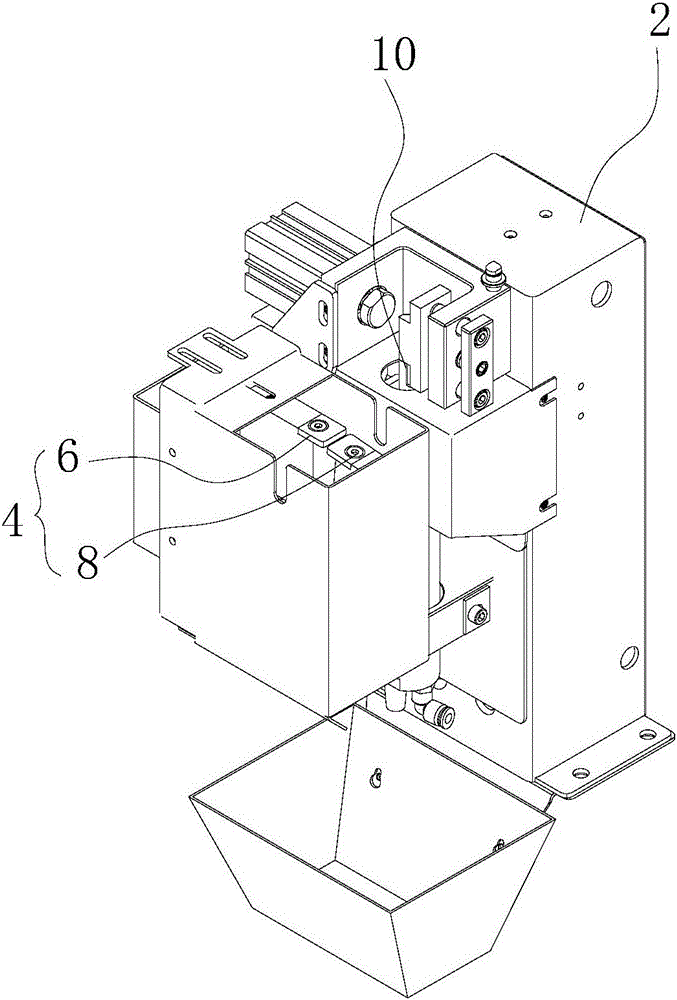

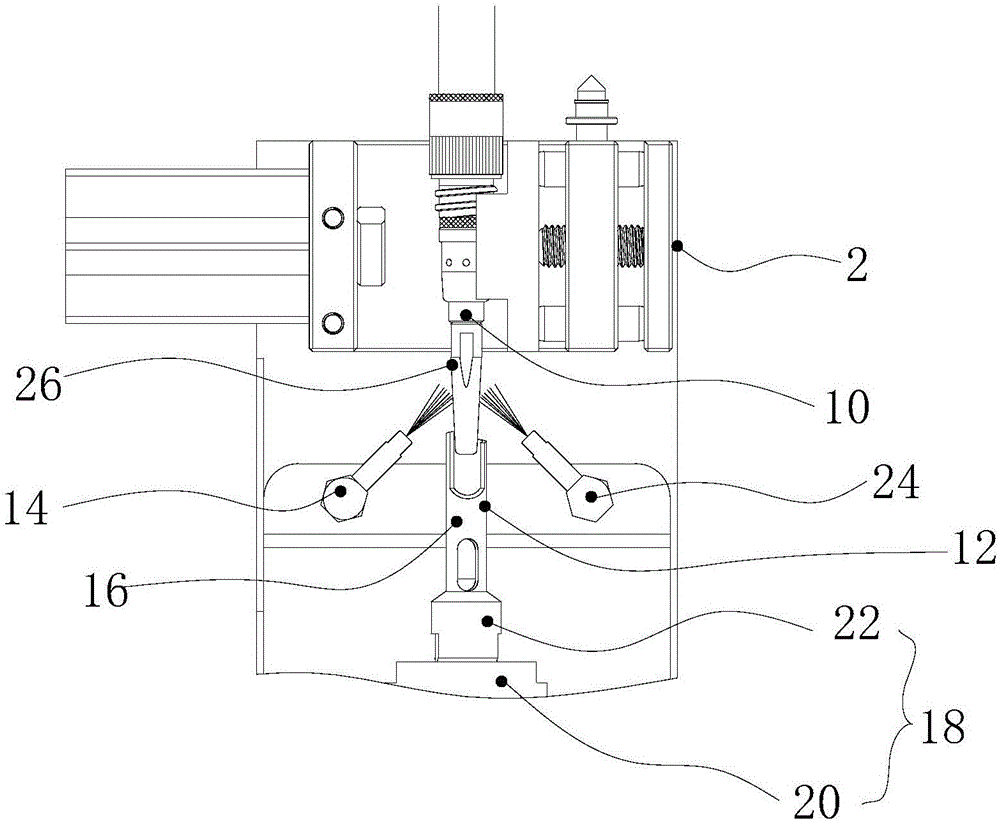

[0034] Such as Figure 1-3 As shown, the present invention comprises frame 2, is characterized in that, described frame 2 is provided with:

[0035] The wire cutting device 4 comprises a fixed baffle 6 fixed on the frame 2 and a movable plate 8 capable of reciprocating linear motion relative to the fixed baffle 6, and the movable plate 8 is provided with a the first blade contacted by the plate 6;

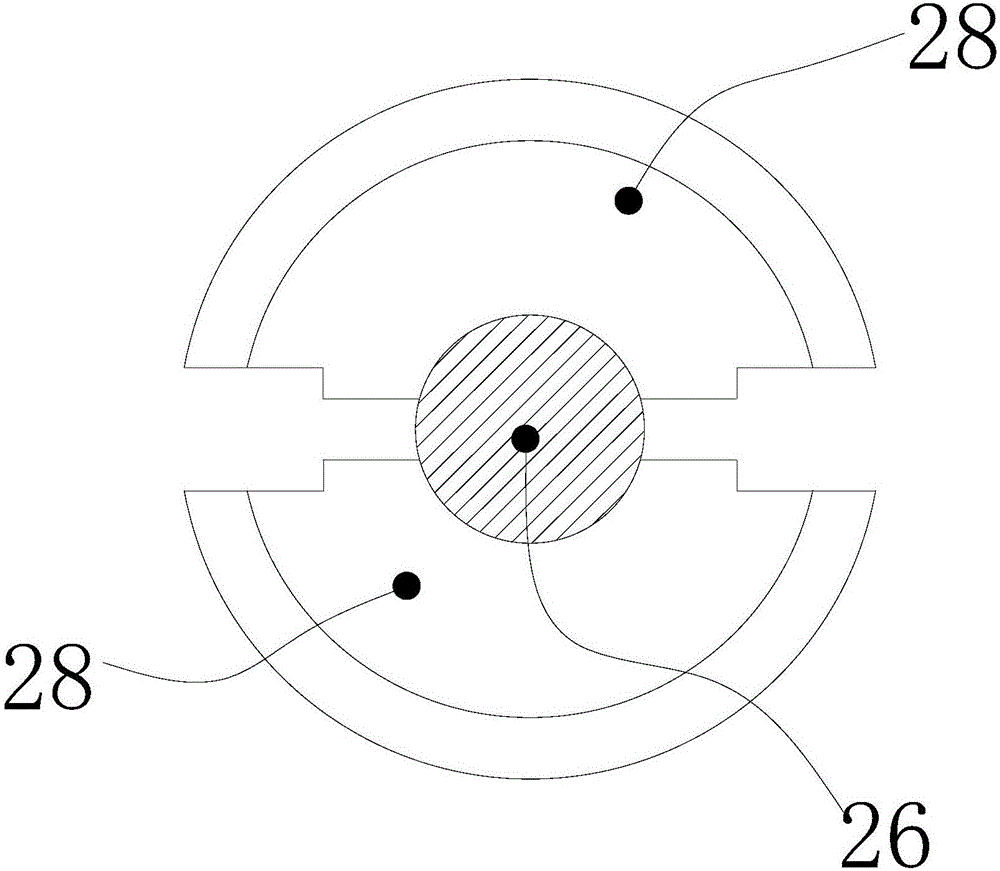

[0036] A torch cleaning device, which includes a fixing mechanism 10, a slag removal mechanism 12 and an oil injection mechanism 14, wherein the fixing mechanism 10 is fixed on the frame 2, and it is used for clamping the welding torch, and the slag removal The mechanism 12 is located below the fixing mechanism 10, and it can remove slag on the inner wall of the welding torch after clamping. The fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com