Alkaline smelting flux used for submerged arc welding and application

A technology of smelting flux and submerged arc welding, which is applied in arc welding equipment, welding medium, welding equipment, etc., can solve the problem of poor welding process performance, poor surface shape and slag removal performance, difficult process performance and low temperature toughness, and weld metal impact toughness Poor problems, good slag removal performance, good slag removal performance, and smooth weld bead surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

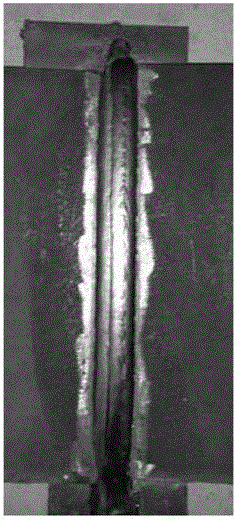

Image

Examples

Embodiment 1

[0016] According to the mass percentage, weigh 14% CaF respectively 2 , 7% CaO, 11.2% MgO, 28% SiO 2 , 22% Al 2 o 3 , 10% MnO 2 , 1.5% TiO 2 , 1.5% K 2 CO 3 , 3% B 2 o 3 , 1.8% FeO. Mix and stir the above-mentioned weighed raw materials, and get a uniform mixed powder after stirring evenly. Put the uniform mixed powder into a graphite crucible and put it in a melting furnace for melting. State semi-finished products. The obtained glass semi-finished product was placed in a drying oven for drying at a drying temperature of 120° C. and kept for 48 hours. Crushing the dried glassy semi-finished product to a particle size within the range of 250-350 μm to obtain the finished smelted flux. Weld the 12MnNiVR structural steel with the obtained smelted flux and US-49 welding wire, and the obtained performance indicators are as follows: the tensile strength is 710MPa, the bending test (side bending 180°) is qualified, the impact absorption energy (weld area) is 112.9J, and t...

Embodiment 2

[0018] According to the mass percentage, weigh 10% CaF respectively 2 , 13% CaO, 20.8% MgO, 19% SiO 2 , 19% Al 2 o 3 , 8% MnO 2 , 2% TiO 2 , 2% K 2 CO 3 , 3.5% B 2 o 3 , 2.7% FeO. Mix and stir the above-mentioned weighed raw materials, and get a uniform mixed powder after stirring evenly. Put the uniform mixed powder into a graphite crucible and put it in a melting furnace for melting. State semi-finished products. The obtained glass semi-finished product was placed in a drying oven for drying at a drying temperature of 120° C. and kept for 48 hours. Crushing the dried glassy semi-finished product to a particle size within the range of 250-350 μm to obtain the finished smelted flux. Welded the 12MnNiVR structural steel with the obtained smelted flux and US-49 welding wire. The obtained performance indicators are as follows: the tensile strength is 696MPa, the bending test (side bending 180°) is qualified, the impact absorption energy (weld area) is 129.1J, and the s...

Embodiment 3

[0020] According to the mass percentage, weigh 10% CaF respectively 2 , 20% CaO, 32% MgO, 15% SiO 2 , 10% Al 2 o 3 , 8% MnO 2 , 1% TiO 2 , 1% K 2 CO 3 , 2.5% B 2 o 3 , 0.5% FeO. Mix and stir the above-mentioned weighed raw materials, and get a uniform mixed powder after stirring evenly. Put the uniform mixed powder into a graphite crucible and put it in a melting furnace for melting. State semi-finished products. The obtained glass semi-finished product was placed in a drying oven for drying at a drying temperature of 120° C. and kept for 48 hours. Crushing the dried glassy semi-finished product to a particle size within the range of 250-350 μm to obtain the finished smelted flux. Welded the 12MnNiVR structural steel with the obtained smelted flux and US-49 welding wire. The obtained performance indicators are as follows: the tensile strength is 682MPa, the bending test (side bending 180°) is qualified, the impact absorption energy (weld area) is 153.4J, and the sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com