Anti-blocking processing system for welding gun nozzles for carbon dioxide arc welding

A gas protection and processing system technology, applied in the direction of cleaning welding torches, welding accessories, etc., can solve the problems of increasing the labor intensity of operators and the difficulty of realizing automatic control of welding production lines, so as to avoid clogging of welding torch nozzles, facilitate automatic control, The effect of meeting welding quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

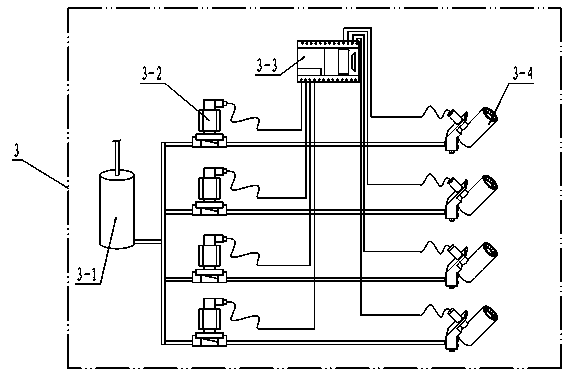

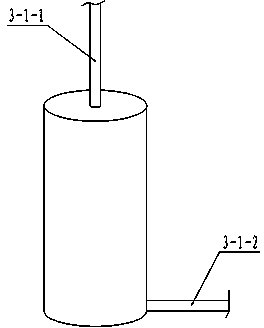

[0025] see figure 2 , Fig. 3, the present invention comprises liquid storage tank 3-1, anti-splash liquid spraying device, welding torch placement frame 3-4) and PLC control mechanism 3-3, and anti-splash liquid is housed in described liquid storage tank 3-1, in A compressed air inlet pipe 3-1-1 is provided on the top of the liquid storage tank 3-1, and a liquid outlet pipeline 3-1-2 is provided at the bottom of the liquid storage tank 3-1. The anti-splash liquid spraying device includes a set of quantity and The number of anti-splash liquid spraying units 3-2 matching the number of welding torches in the welding production line is connected in parallel on the outlet pipeline of the liquid storage tank, and its action is controlled by the PLC control mechanism 3-3. At the end of each anti-splash liquid spraying unit 3-2 Set the welding torch holder 3-4.

[0026] see figure 2 , Figure 4 , Figure 7 , the anti-splash liquid spraying unit 3-2 of the present invention compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com