Method and equipment for cleaning welding torch

A technology for cleaning equipment and welding torches, which is applied in the direction of cleaning welding torches and welding accessories, and can solve problems such as failure of devices or control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

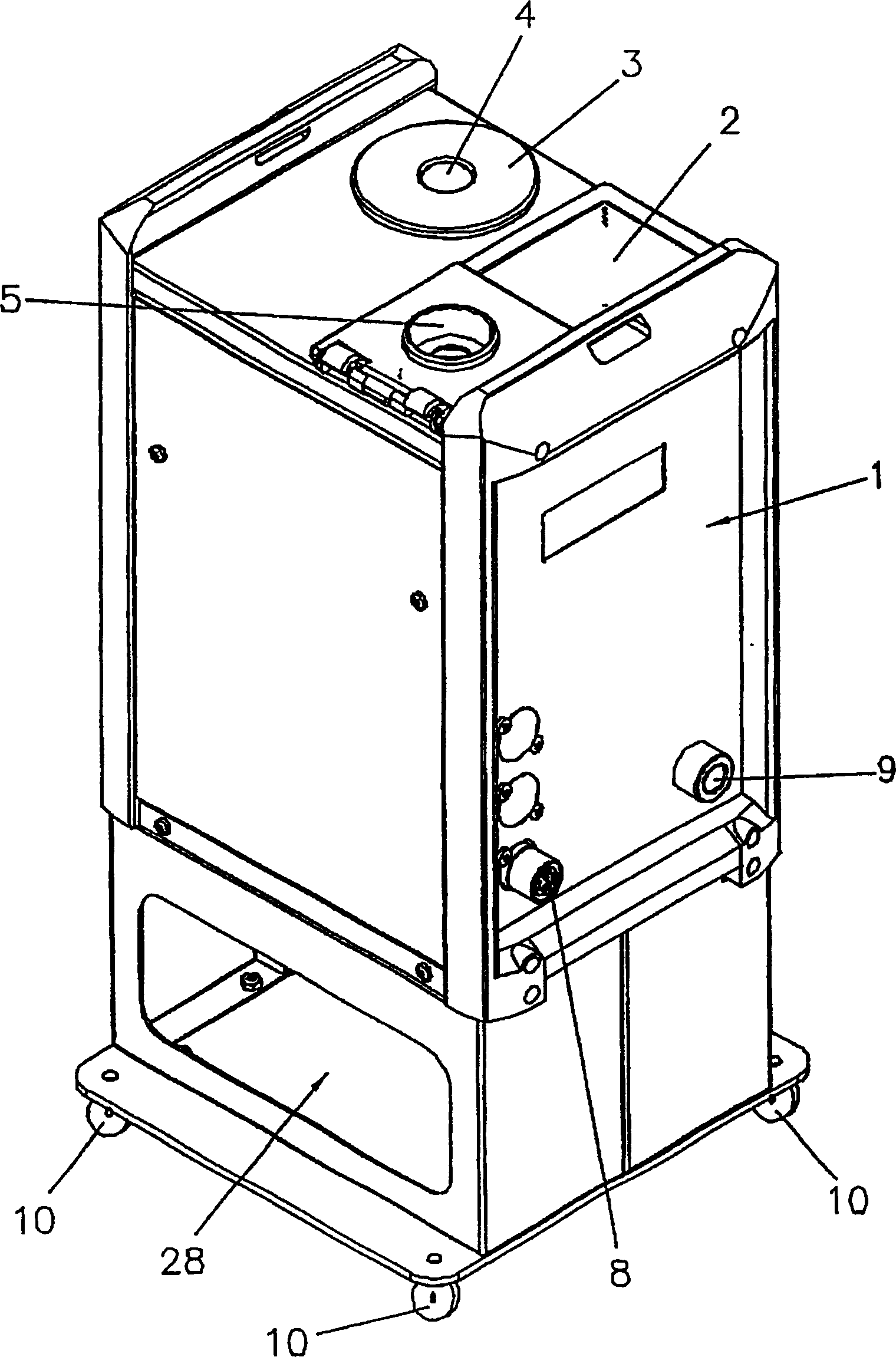

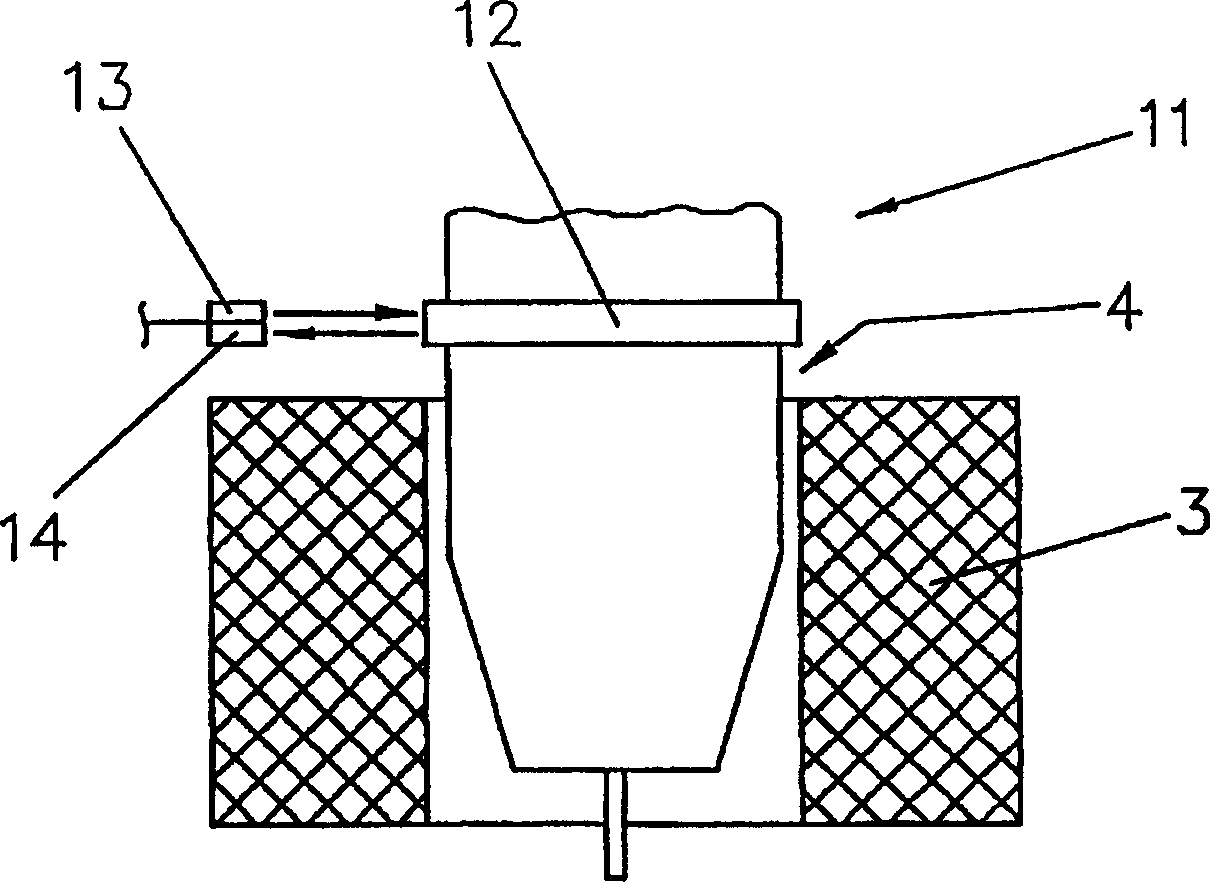

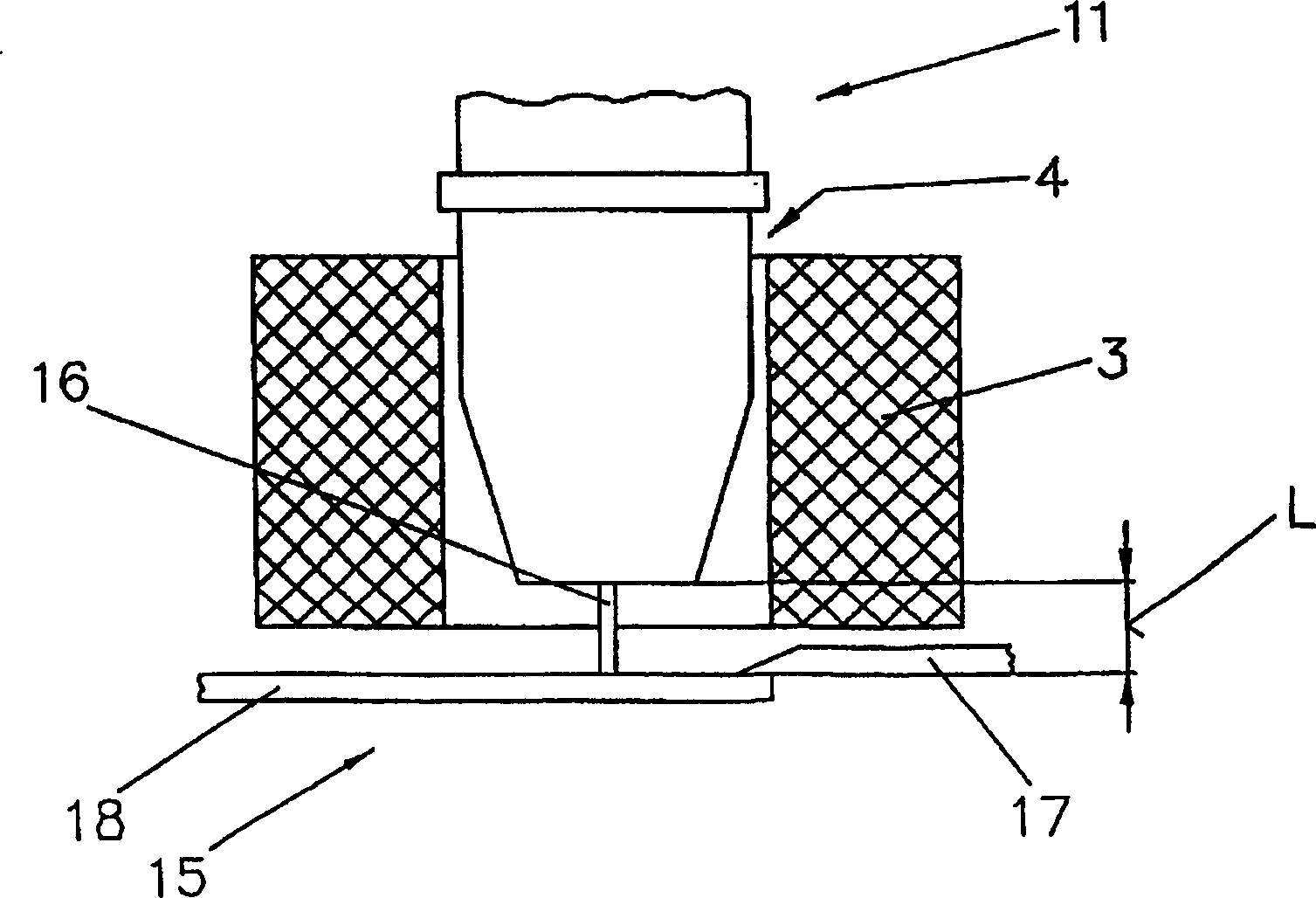

[0067] figure 1 is a perspective view of a cleaning device comprising a housing 1 arranged in a manner similar to a kitchen cabinet and containing all parts arranged for cleaning a welding torch. In this way, a tank 2 is provided in the housing 1 for holding, for example, a cleaning liquid, into which the welding torch can be dipped in order to cool the metal spatter adhering thereto. In addition to the liquid tank 2, a supplementary container 5 can be provided for supplying the tank 2 with liquid. A coil 3 is arranged behind the slot 2 , the coil comprising the opening 4 . The welding torch is inserted into the opening 4 of the coil 3 after immersion in the tank 2 . After power is supplied to the coil 3, the metal spatter on the welding torch is removed in a non-contact manner. The impurities fall into a waste container 6 (not shown) arranged below the coil 3 . After opening a part of the housing 1, the waste container 6 can be easily removed and emptied. A power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com