Fusion electrode gas protection welding gun

A technology of melting electrode gas and gun body, applied in electrode accessories, cleaning torch, characteristics of welding rod, etc., can solve the problem of difficulty in cleaning welding slag, and achieve the effect of improving welding slag cleaning, improving concentricity and preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0038] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

[0039] A preferred embodiment is given below:

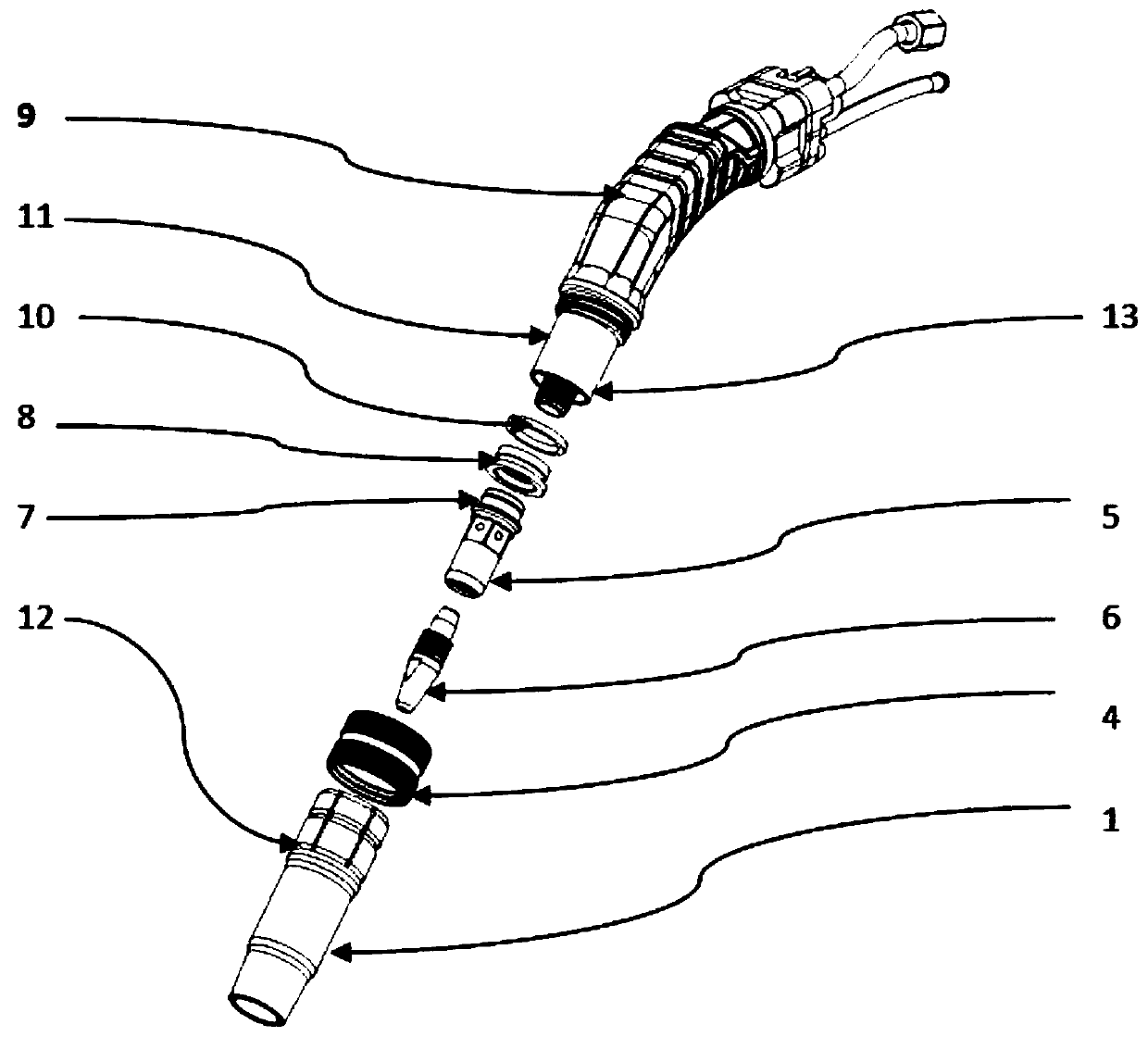

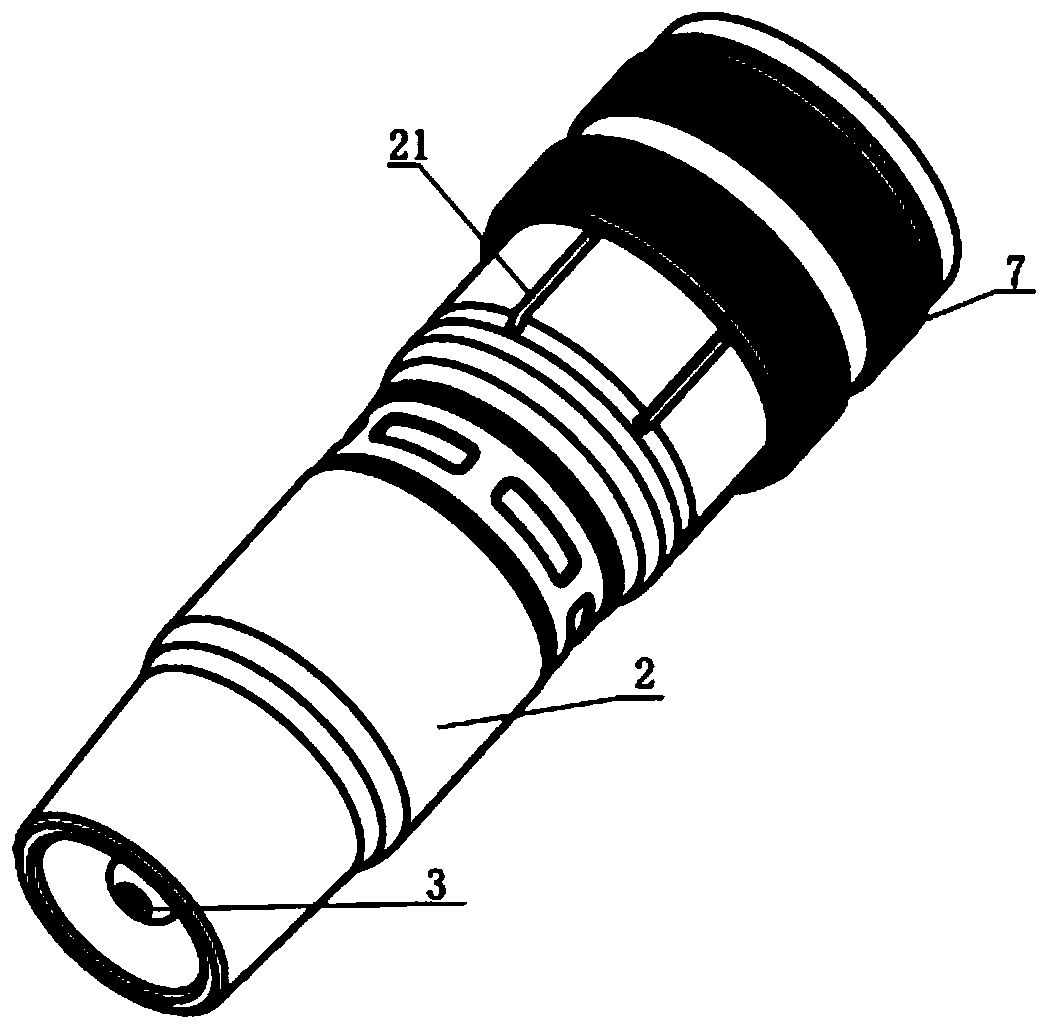

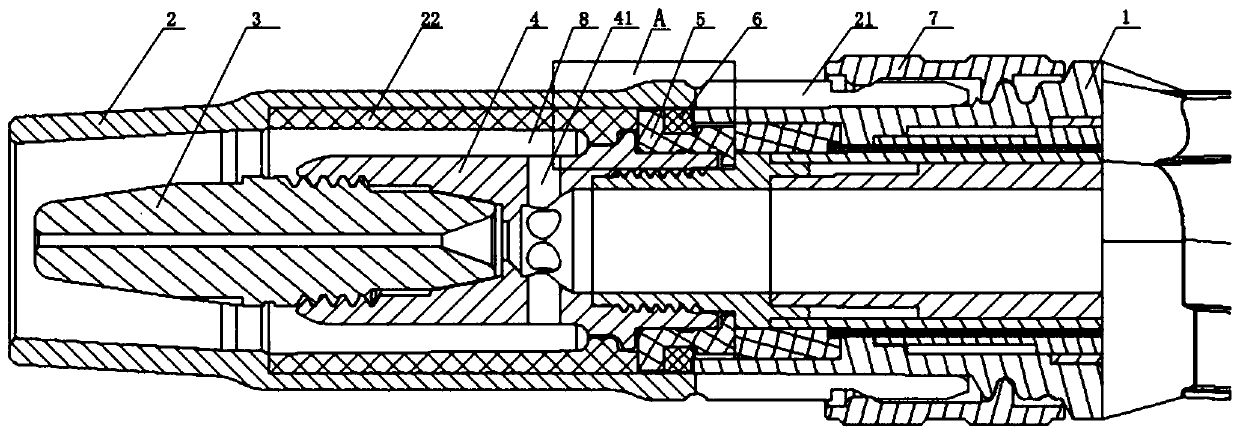

[0040] as attached figure 1 , 2 , 3, the water-cooled torch of this embodiment is mainly composed of torch elbow 1, nozzle 2, contact tip 3, contact tip seat 4, contact tip seat insulating sleeve 5, gasket 6 and locking ring 7.

[0041] The structure of the welding torch elbow 1 is the same as that of the existing known welding torch elbow, the inside of which is a processed tubular part, and the outside is molded by polymer composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com