Cleaning device for mechanically cleaning gas nozzle of gas-shielded welding torch

A technology for gas nozzles and cleaning equipment, which is applied in the directions of cleaning welding torches, cleaning methods using tools, cleaning hollow objects, etc., can solve the problems of difficult mechanical cleaning, difficult access, high cost, and achieves simple construction and operation, and the cost is favorable , the effect of functional safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

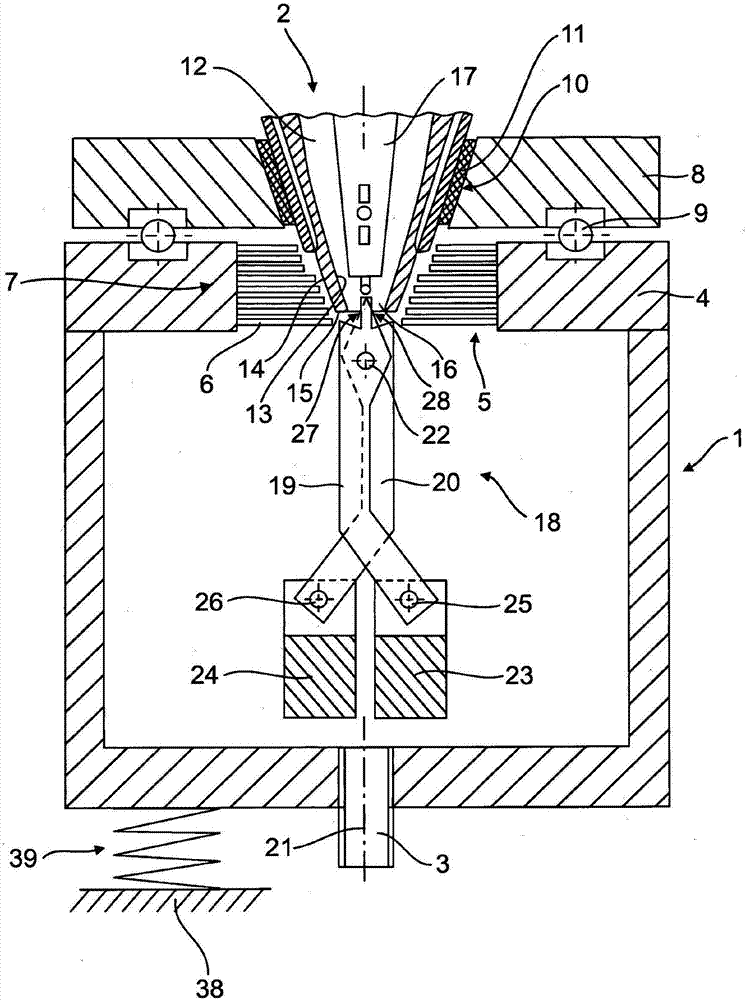

[0036] exist figure 1 shows a cross-sectional view of a cleaning head 1 of a cleaning device (not shown in further detail) for mechanically cleaning the gas nozzles 2 of a shielding gas welding torch, in particular a CMT+ welding torch. The cleaning head 1 is designed as a cylindrical hollow body in the shape of a pot or cage and can be rotated by means of a controllable rotary drive (not shown) via a central drive shaft 3 on the bottom side. The upper wall 4 of the cleaning head 1 has a central insertion opening 5 , wherein a conically shaped brush ring 7 is formed with radially inwardly facing plastic bristles 6 .

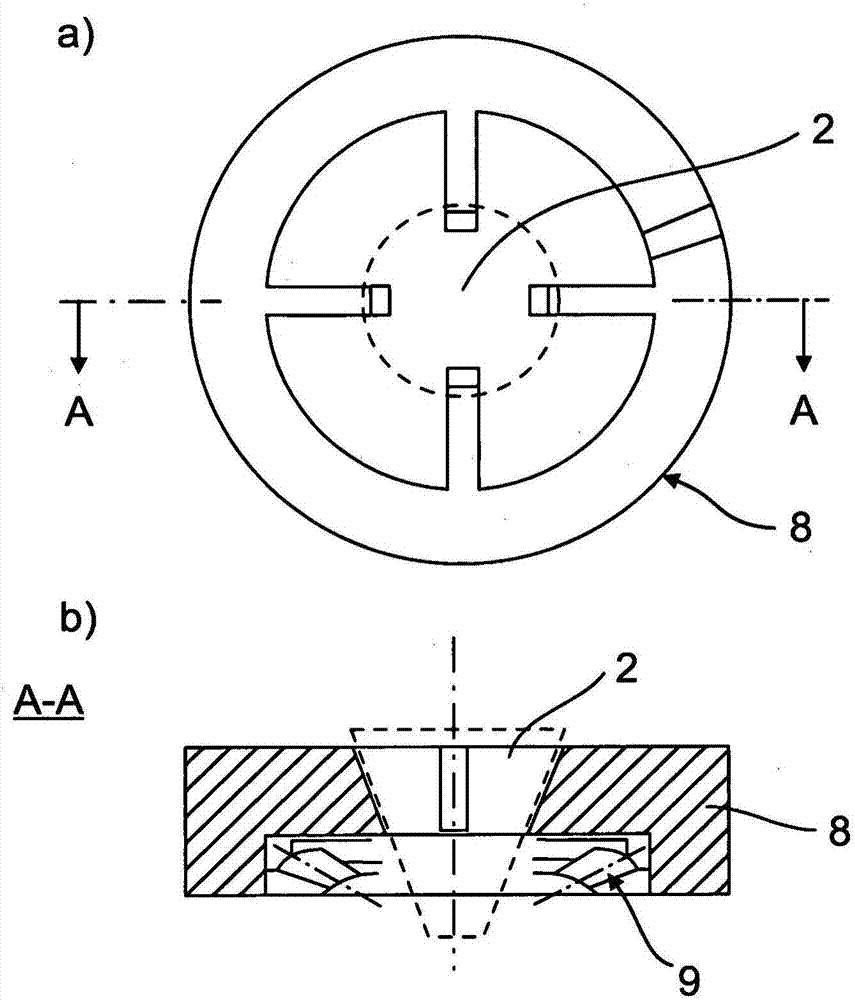

[0037] On the upper wall 4, the centering aid 8 is mounted by means of a spherical or conical bearing ring 9 in such a way that when the hollow body of the cleaning head rotates, the centering aid 8 passes through a not shown support or housing fixed in place. The connection is held in a non-rotatable manner.

[0038] The centering aid member 8 has a centering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com