Method of cleaning a contact tube of a welding torch, and a welding torch and contact tube

A conductive tube and clean technology, applied in the field of conductive tubes, can solve the problems of unusable production of welding equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

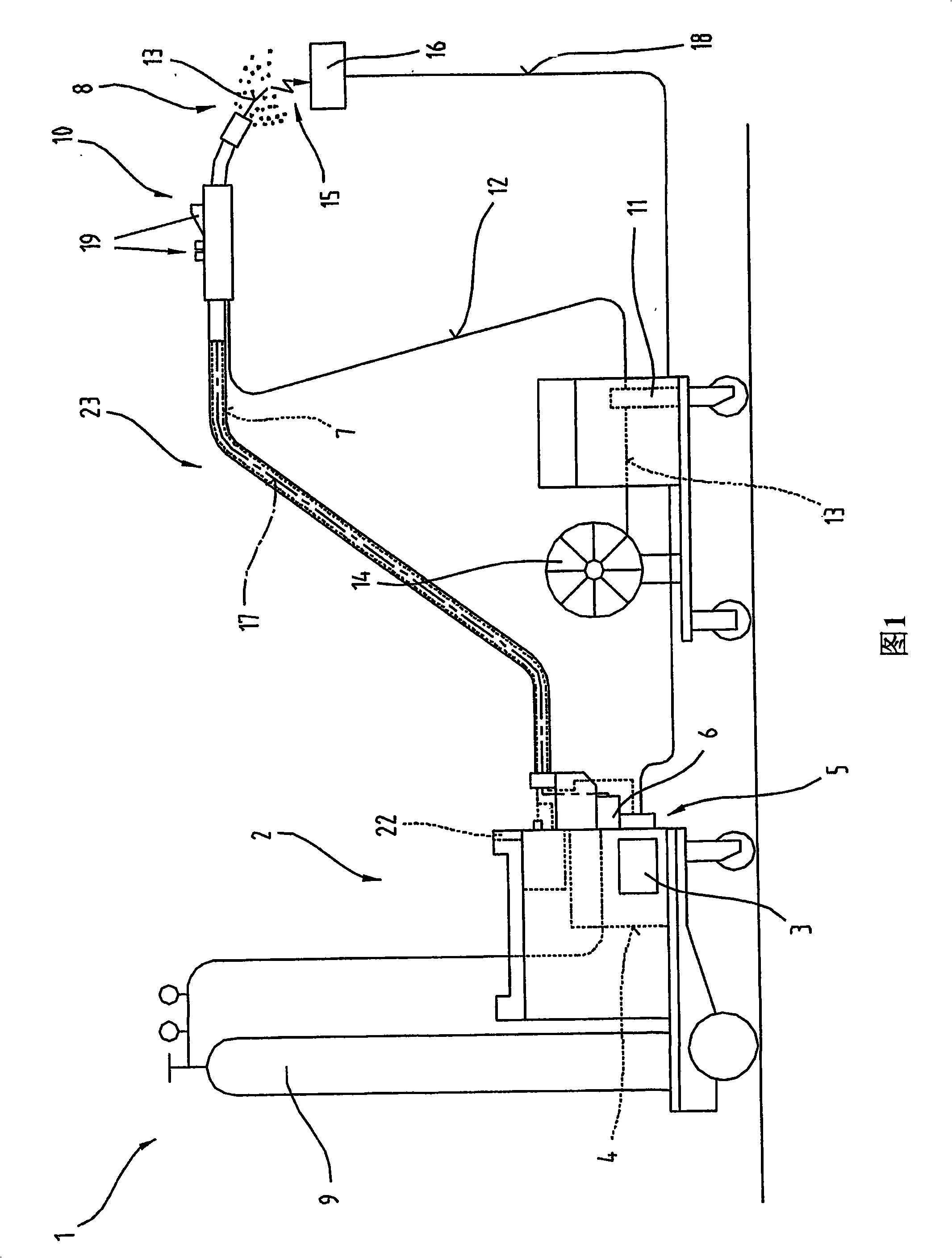

[0048] In FIG. 1 , a welding device 1 is shown for most different welding processes, such as MIG / MAG welding and / or WIG / TIG welding or electrode welding, twin wire / tandem welding, etc.

[0049] The welding device 1 comprises a current source 2 with a power element 3 , a control unit 4 and switching means 5 associated with the power element 3 and / or the control unit 4 . The switching member 5 and / or the control unit 4 are connected to a control valve 6 which is followed by a protective gas 8 such as CO 2 A supply line 7 of , helium or argon is arranged between the gas reservoir 9 and the welding torch 10 .

[0050] Furthermore, a wire feeder 11 usually used for MIG / MAG welding can be activated by means of the control unit 4 , and welding wire 13 is fed by means of a reel 14 via a supply line 12 into the region of the welding torch 10 . The wire feeder 11 can be designed as an accessory or integrated into the welding device 1 .

[0051] The current for establishing the arc 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com