Rotating arc narrow gap welding torque

A rotating arc and narrow gap technology, applied in the direction of electrode accessories, electrode characteristics, electrode support devices, etc., can solve the problems of poor conduction, large brush wear, and difficult electrode access, etc., and achieve low cost, stable rotation, and power connection. Easy and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

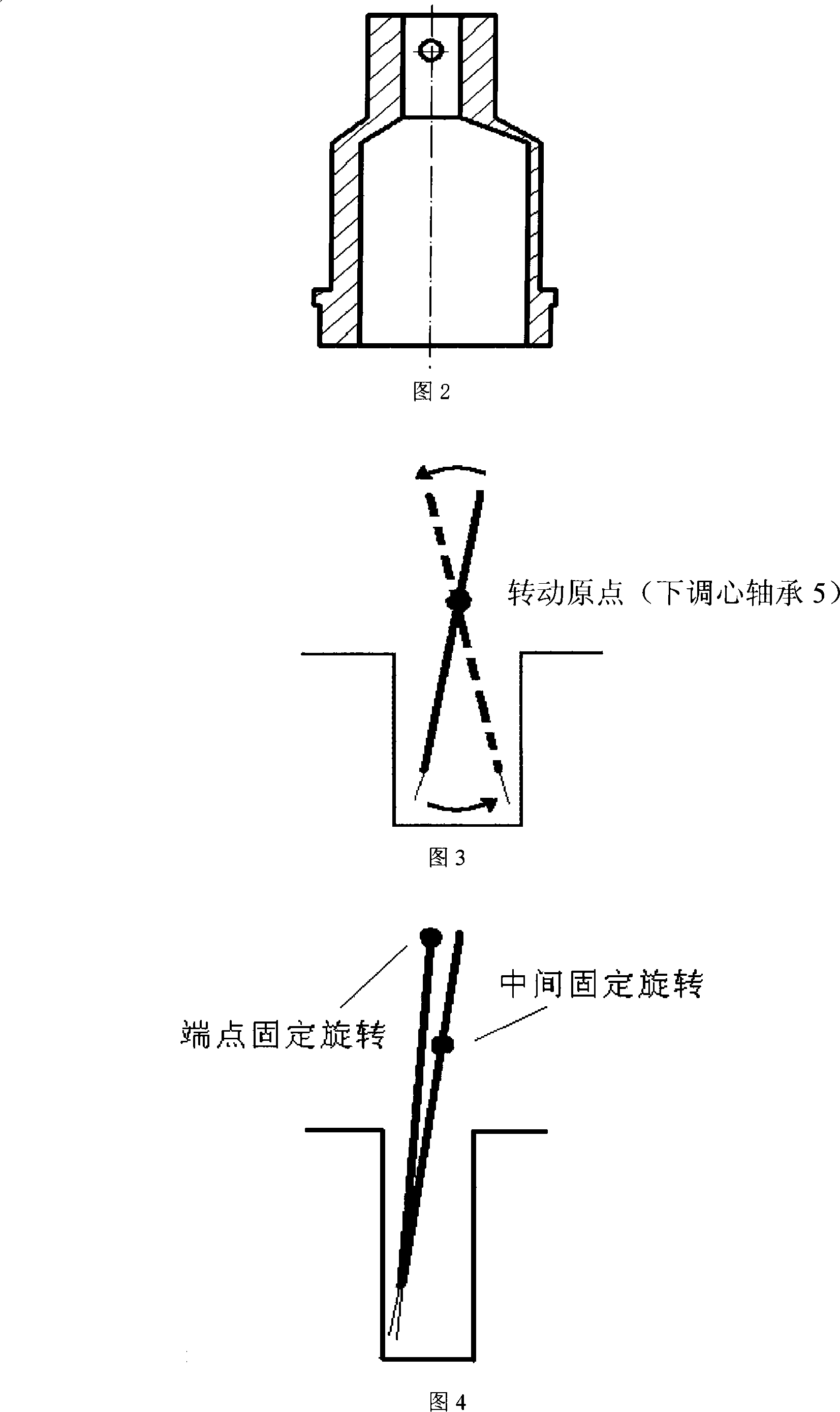

[0021] The principle of the invention is: the motor drives the conductive rod and the conductive tip to rotate eccentrically around the central axis of the welding torch through the eccentric sleeve, the conductive tip only revolves, but does not rotate, and the welding wire is sent out from the center of the conductive tip, so that there is only There is almost no relative movement in the axial direction and there is almost no relative movement in the circumferential direction, thereby reducing wear and achieving the purpose of improving the rotation stability of the welding torch and increasing the life of the welding torch.

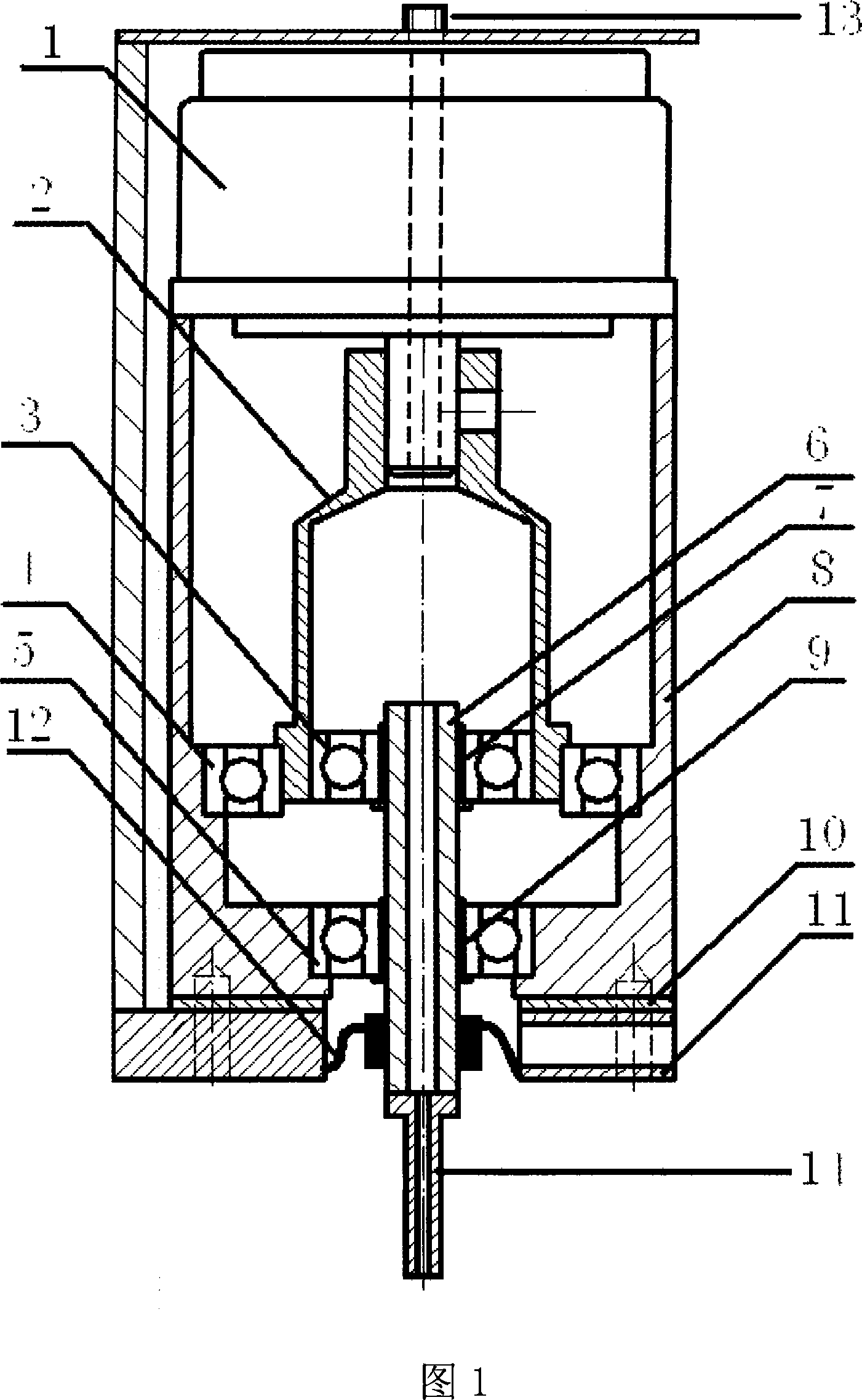

[0022] Below in conjunction with accompanying drawing 1,2 the structural composition and working process of welding torch are described. The eccentric rotating part of the welding torch is shown in Figure 1. It mainly consists of a hollow shaft high-speed servo motor 1, an eccentric sleeve 2, an upper center bearing 3, a sealed bearing 4, a lower center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com