Torch and contact tip for gas metal arc welding

A gas shielding and contact tip technology, which is applied in arc welding equipment, metal processing equipment, gas fuel burners, etc., can solve the problem of hindering the smooth supply of welding wire into the welding pool, disturbing the quality of welding arc welding, hindering the flow of shielding gas, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following description of specific exemplary embodiments is exemplary in nature and is not intended to limit the invention and its application or uses.

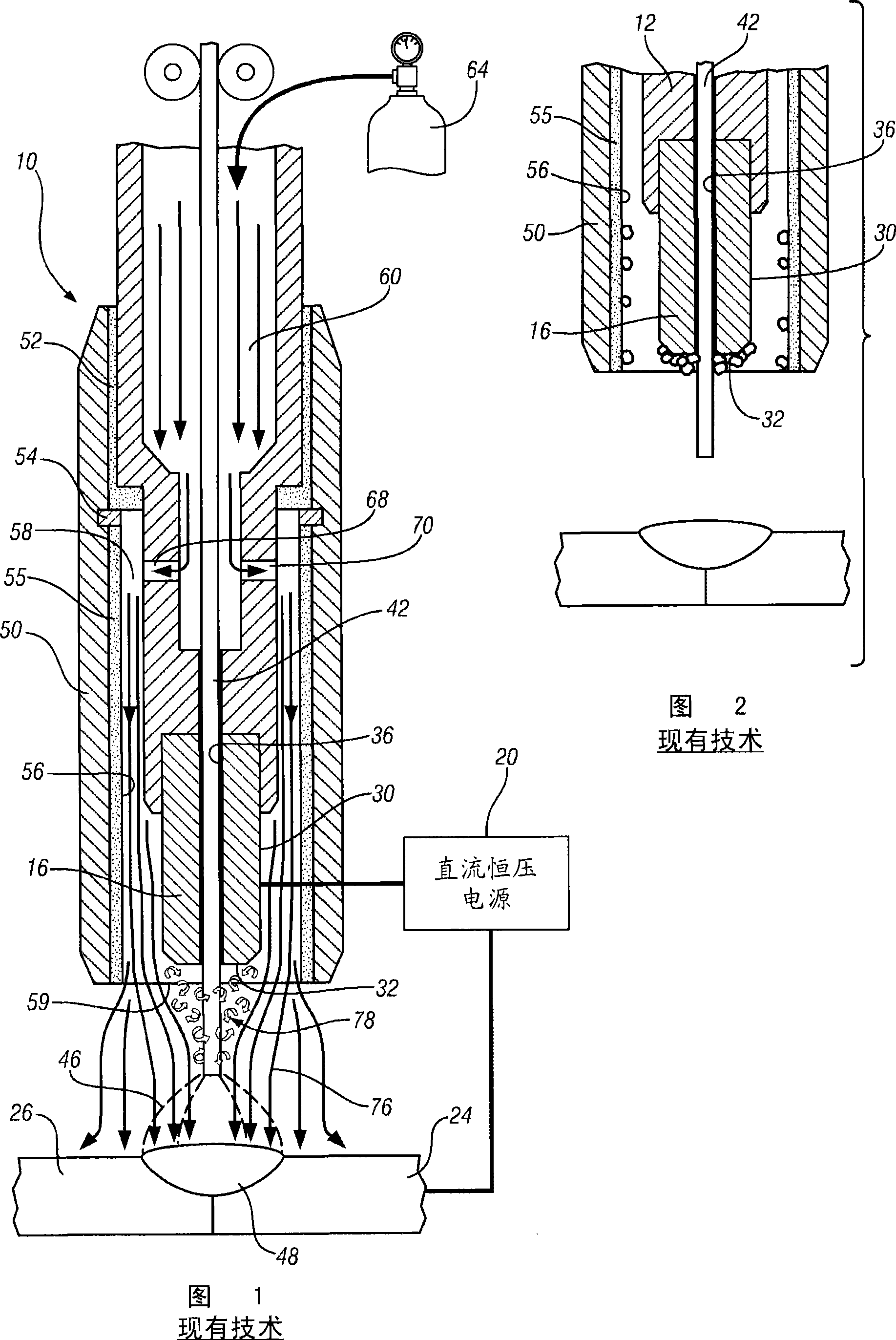

[0015] Fig. 1 is an overall sectional view of a conventional welding torch used for gas metal arc welding. The welding torch, indicated generally at 10 , includes a housing 12 in which a contact tip 16 is mounted. Housing 12 may be attached to the handle of a welding torch, not shown, and operated by a welder, or housing 12 may be operated by a robot or other manipulator. As shown in FIG. 1 , housing 12 supports contact tip 16 over workpieces 24 and 26 to be welded together. Contact tip 16 is generally cylindrical and has a cylindrical outer surface 30 and a circular end surface 32 . The electrode hole 36 penetrates the contact tip 16 in the axial direction. Contact tip 16 is typically made of a conductive material such as copper. The contact tip 16 is electrically connected to a welding power source 20 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com