Device for entering and exiting of shielding gas on two sides of forming bin of metal 3D printing equipment

A technology of 3D printing and shielding gas, which is applied to the improvement of process efficiency, additive manufacturing, and additive processing. It can solve the problems of laser power attenuation, difficulty in continuing the printing process, and poor quality of molded parts, so as to prevent air flow disorder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

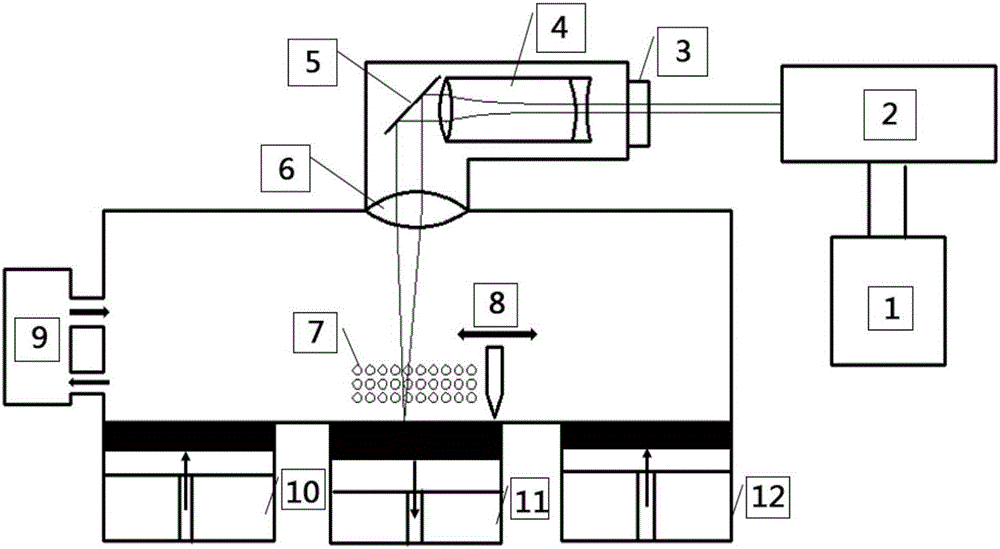

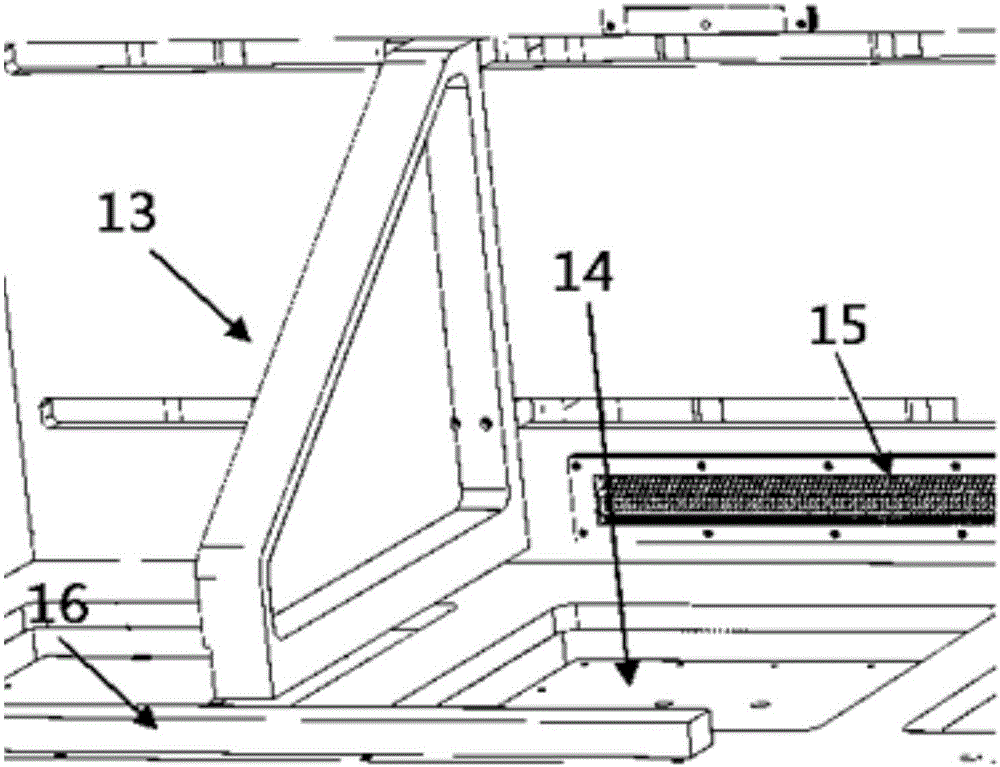

Method used

Image

Examples

specific Embodiment

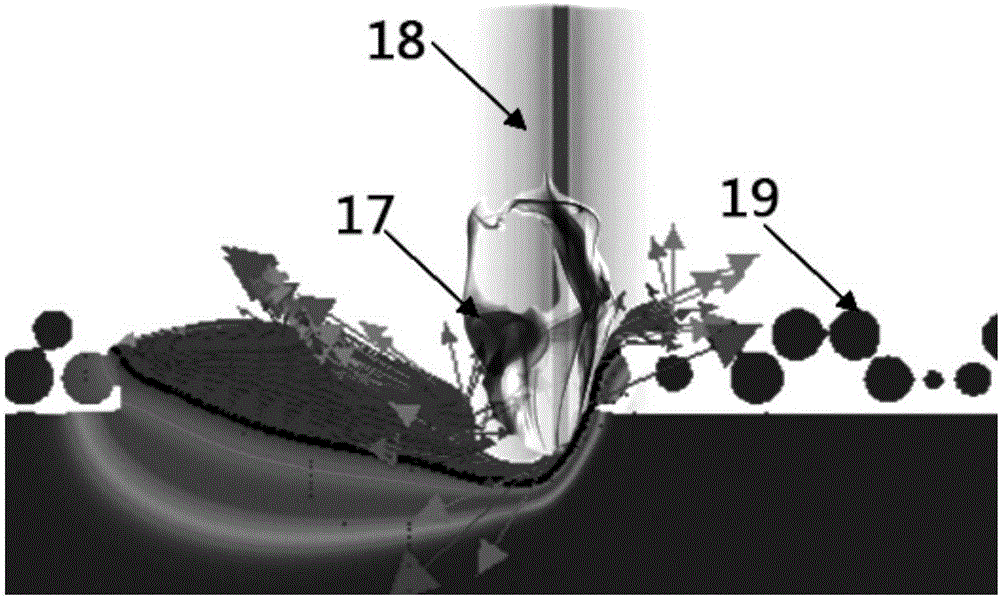

[0044] This embodiment is that the air inlet and outlet device in the selective laser melting equipment is placed on the aluminum alloy engine impeller ( Figure 8.A ) application in the manufacturing process. It is well known that aluminum alloy powder is lighter than other metal powders, and its fluidity is poor, the effect of powder spreading is not good, and it is easy to generate dust. Therefore, during the process of selective laser melting, black smoke and sparks are easily generated above the molten pool. And if Figure 8.B As shown, some engine impellers are larger in size, so the section at the bottom is larger.

[0045] When choosing a general horizontal air inlet and outlet device, it is difficult to blow away a large number of black particles and smoke in time because the air flow does not form a strong and stable laminar flow. At this time, the laser power will be greatly attenuated, resulting in the bottom powder cannot be melted penetration, and irregular mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com