Impulsive arc welding powder supply

A technology of welding power supply and pulsed arc, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., and can solve problems such as the inability to manage the arc length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

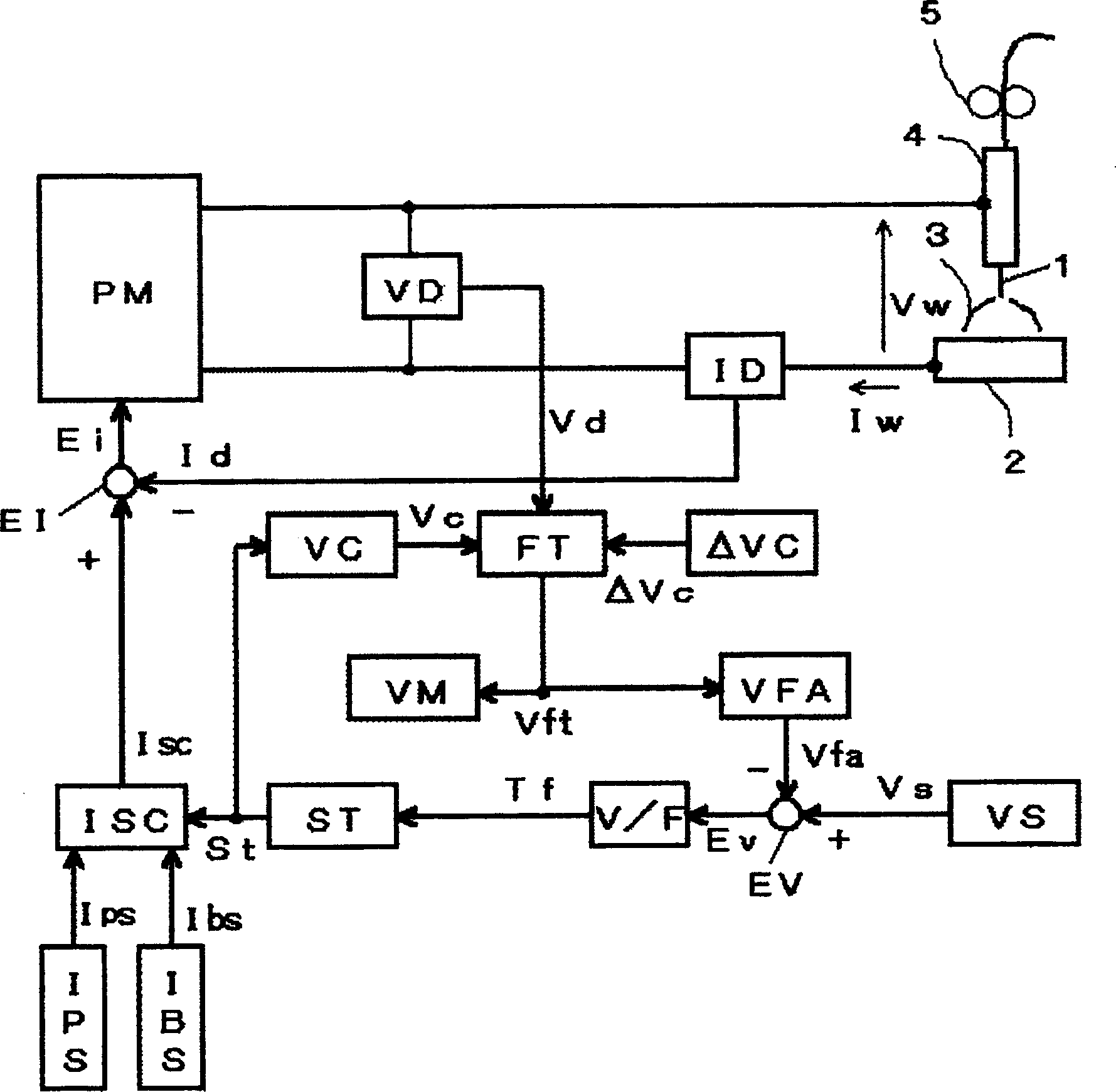

[0031] figure 1 It is a block diagram of the pulse arc welding power supply according to the embodiment of the present invention. Hereinafter, each block will be described with reference to the drawings.

[0032] The power supply main circuit PM takes a commercial AC power supply (3-phase 200V, etc.) as input, performs output control such as inverter control and chopper control based on the following current error amplification signal Ei, and outputs welding voltage Vw suitable for welding and Welding current Iw. The welding wire 1 is fed inside the welding torch 4 by the rotation of a wire feed roller (roll) 5 of the wire feeding device, and an arc 3 is generated between the welding wire 1 and the base material 2 .

[0033] The voltage detection circuit VD detects the aforementioned welding voltage, and outputs a welding voltage detection signal Vd. The reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com