Preparation method of carbon-coated cobalt oxygen evolution reaction electro-catalyst

A technology of oxygen evolution reaction and electrocatalyst, which is applied in the field of electrochemical catalyst preparation, can solve the problems of low catalytic current density, high overpotential and poor stability, and achieve good catalytic performance, simple steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

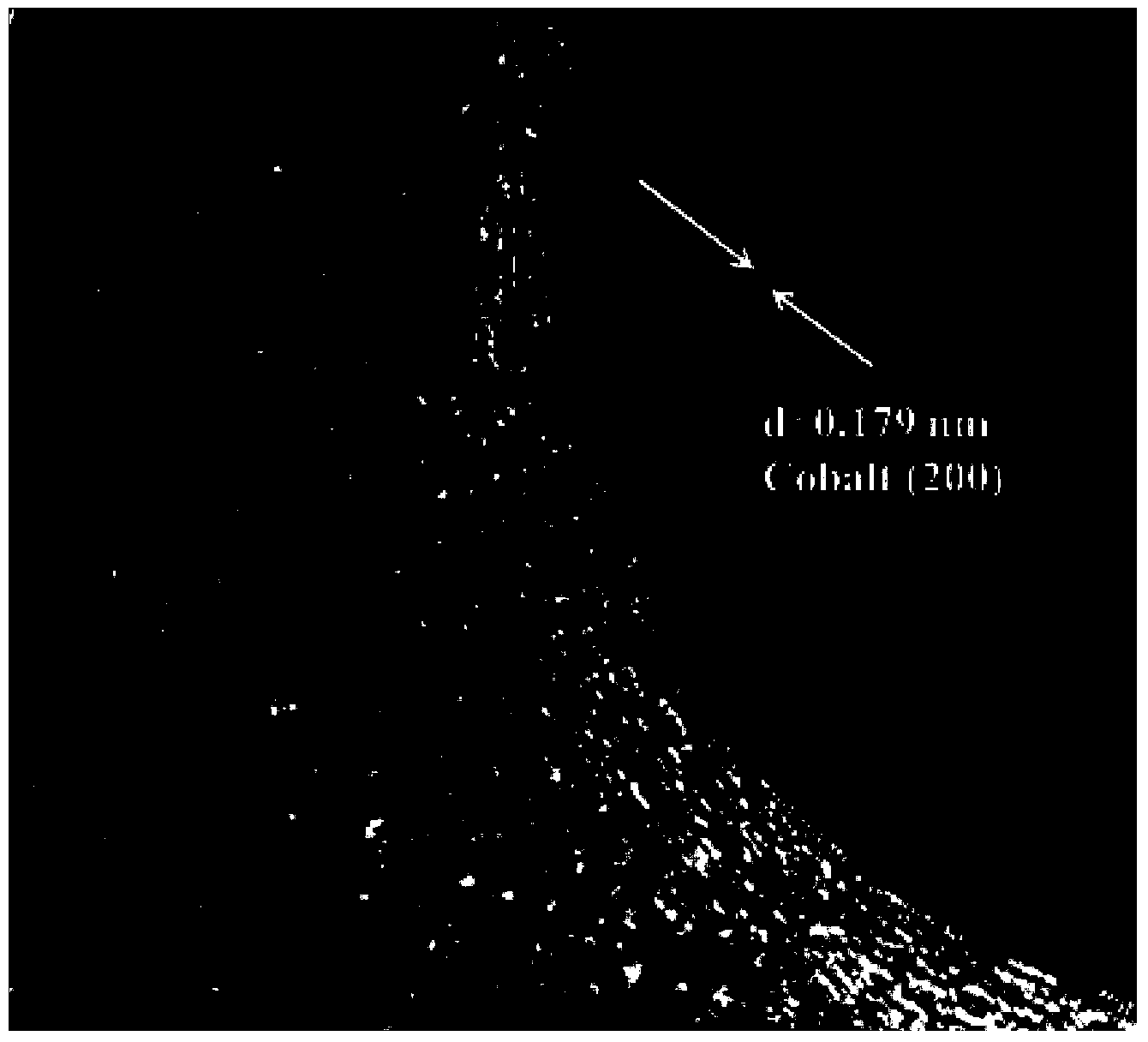

[0034] The carbon-coated cobalt oxygen evolution reaction electrocatalyst is a composite material composed of graphite with good electrical conductivity and cobalt oxide with high catalytic activity.

[0035] The preparation method of a carbon-coated cobalt oxygen evolution reaction catalyst of the present invention, the specific preparation steps are as follows:

[0036] 1) Dissolve 0.29g of cobalt nitrate hexahydrate and 6.006g of urea (molar ratio: 1:100) in deionized water, and ultrasonically disperse to obtain a uniformly mixed solution; the mixed solution is heated in a water bath and evaporated to dryness to obtain a powder;

[0037] 2) After heating and evaporating to dryness in step 1), the powder was obtained, heated to 900°C under the protection of argon, and kept at a constant temperature for 1 hour, and the carbon-coated cobalt elemental black powder was obtained after natural cooling;

[0038] 3) The black powder obtained in 2) is dissolved in a mixed solution of...

Embodiment 2

[0049] The carbon-coated cobalt oxygen evolution reaction electrocatalyst is a composite material composed of graphite with good electrical conductivity and cobalt oxide with high catalytic activity.

[0050] A kind of preparation method of carbon-cobalt oxygen evolution reaction catalyst of the present invention, concrete preparation steps are as follows:

[0051] 1) Dissolve 0.29g of cobalt nitrate hexahydrate and 15.015g of urea (molar ratio: 1:250) in deionized water, and ultrasonically disperse to obtain a uniformly mixed solution; heat the mixed solution in a water bath and evaporate to dryness;

[0052] 2) Heat the powder obtained after heating and evaporating to dryness in step 1) to 900°C under the protection of argon, and keep it at a constant temperature for 1 hour, and obtain carbon-cobalt black powder after natural cooling;

[0053] 3) The black powder obtained in 2) is dissolved in a mixed solution of ethanol and naphthol; the mixing volume ratio of ethanol and n...

Embodiment 3

[0057] The carbon-coated cobalt oxygen evolution reaction electrocatalyst is a composite material composed of graphite with good electrical conductivity and cobalt oxide with high catalytic activity.

[0058] A kind of preparation method of carbon-cobalt oxygen evolution reaction catalyst of the present invention, concrete preparation steps are as follows:

[0059] 1) Dissolve 0.29g of cobalt nitrate hexahydrate and 30.03g of urea (molar ratio (1:500)) in deionized water, and ultrasonically disperse to obtain a uniformly mixed solution; heat the mixed solution in a water bath and evaporate to dryness;

[0060] 2) Heat the powder obtained after heating and evaporating to dryness in step 1) to 900°C under the protection of argon, and keep it at a constant temperature for 1 hour, and obtain carbon-cobalt black powder after natural cooling;

[0061] 3) The black powder obtained in 2) is dissolved in a mixed solution of ethanol and naphthol; the mixing volume ratio of ethanol and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com