Full-automatic charging-discharging mechanism used for LED (Light Emitting Diode) laser cutting

A laser cutting and fully automatic technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low efficiency of LED wafer cutting and unstable manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

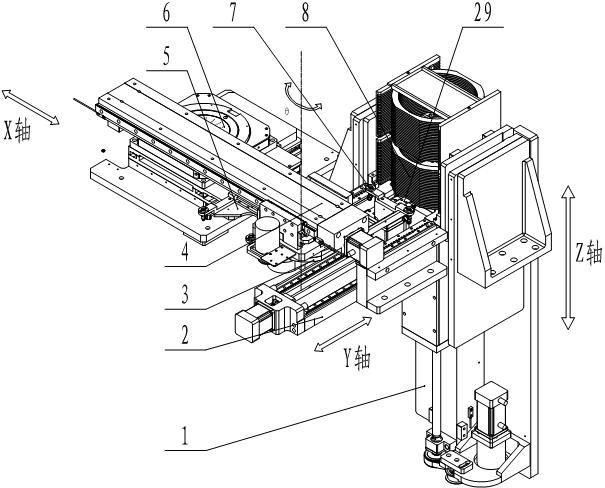

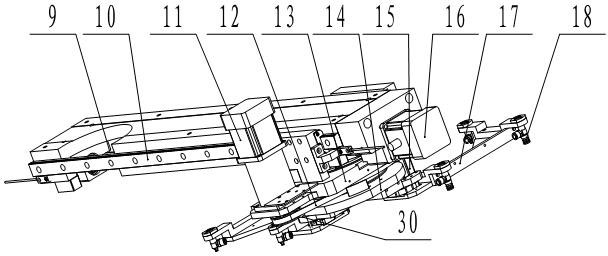

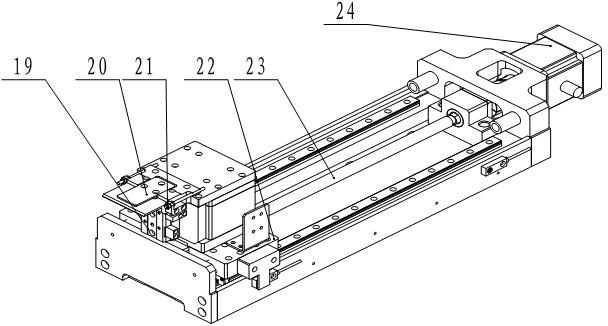

[0020] Such as figure 1 As shown, the fully automatic loading and unloading mechanism applied to LED laser cutting includes mutually independent X-axis transmission unit 4, Y-axis transmission unit 2 and Z-axis transmission unit 1 arranged in X, Y, and Z axes, such as figure 2 As shown, the X-axis transmission unit 4 includes an X-axis ball screw 9, an X-axis linear slide rail 10, an X-axis motor 16, and an X-axis slide plate 13. The X-axis slide plate 13 is placed in the X-axis linear slide rail 10, and the X-axis slide plate 13 and the X-axis ball screw 9 form a screw transmission pair, and the X-axis ball screw 9 is drivingly connected to the X-axis motor 16. The X-axis slide plate 13 is equipped with a rotating shaft 3, and the rotating shaft 3 is driven and connected to the motor through the timing belt 12. The rotating shaft 3 is provided with a first suction cup 5 and a second suction cup 7, the first suction cup 5 and the second suction cup 7 form an angle of 90° in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com