Feeding equipment for poultry farm

A technology for farms and equipment, applied in the field of feeding equipment, can solve the problems of fatigue of breeders, increase the labor intensity of breeders in farms, etc., and achieve the effect of realizing water quantity detection and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

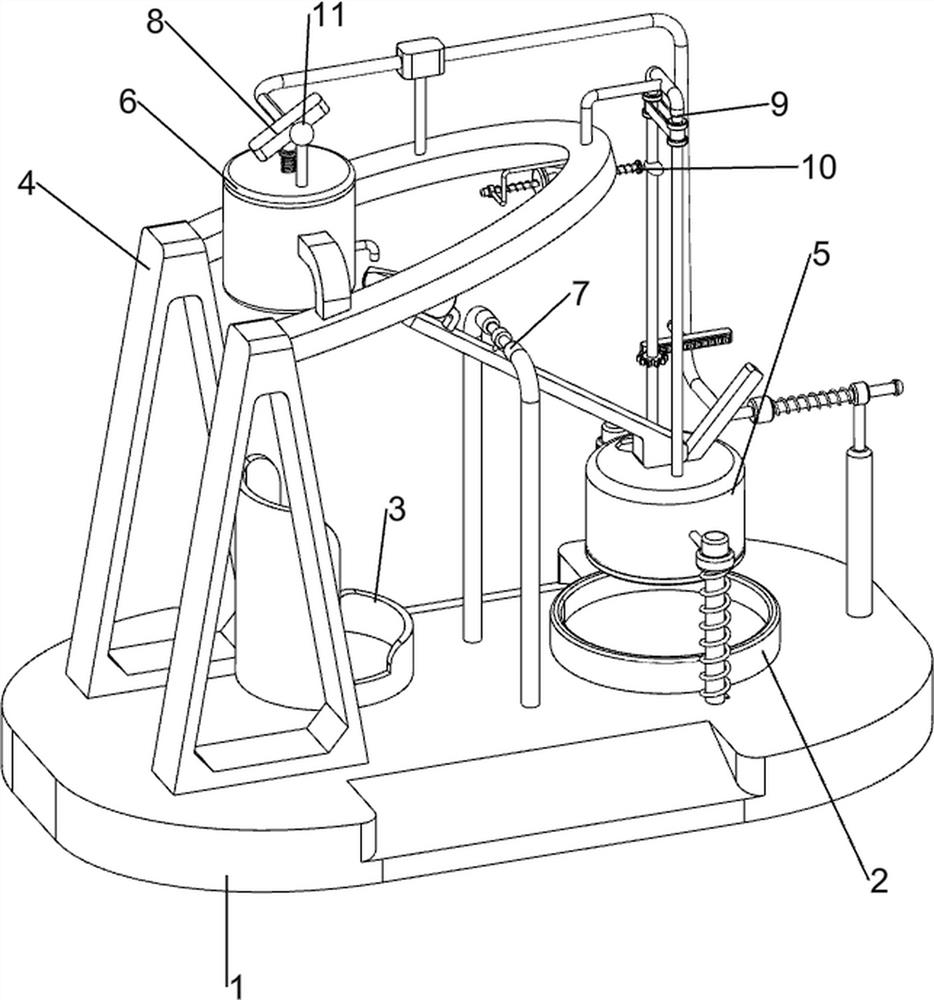

[0067] A kind of feeding equipment for poultry farm, such as figure 1As shown, it includes a base 1, a food trough 2, a water tank 3, a support 4, a feeding mechanism 5 and a water injection mechanism 6, the right side of the base 1 is provided with a food trough 2, the left side of the base 1 is provided with a water tank 3, and the base 1 A support 4 is provided on the upper left side, a blanking mechanism 5 is provided on the upper right side of the base 1, and a water injection mechanism 6 is provided on the upper part of the support 4 .

[0068] When people need to feed poultry in a farm, they can use this feeding equipment for poultry farms. First, people need to pour food into the feeding mechanism 5, and then inject water into the water injection mechanism 6. It will flow into the water tank 3 from the water injection mechanism 6, and people will intermittently beat the feeding mechanism 5 to move downward, so that the food can drop intermittently into the food tank 2,...

Embodiment 2

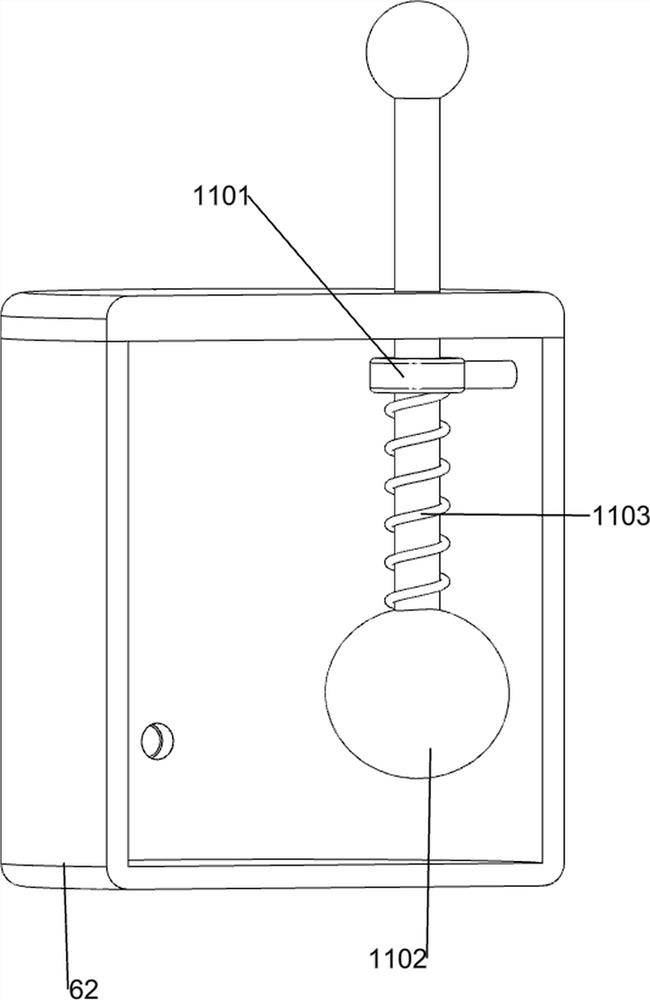

[0070] On the basis of Example 1, such as figure 2 and image 3 As shown, the blanking mechanism 5 includes a first support rod 51, a blanking tank 52, a filter screen 53 and a first spring 54, the base 1 is provided with a first support rod 51 on the front and rear sides of the upper right part, and two first Sliding between the tops of the support rods 51 is provided with a blanking tank 52, and the bottom of the blanking tank 52 is provided with a filter screen 53, and the two first support rods 51 are all wound with a first spring 54, and the two ends of the first spring 54 are respectively connected to the The base 1 is connected with the blanking tank 52.

[0071] People need to pour food into the cutting material. When the poultry comes to look for food beside the trough 2, people can manually push the feeding tank 52 to move downward, the first spring 54 is compressed, and the feeding tank 52 drives the filter screen 53 to Down movement, when people let go, the firs...

Embodiment 3

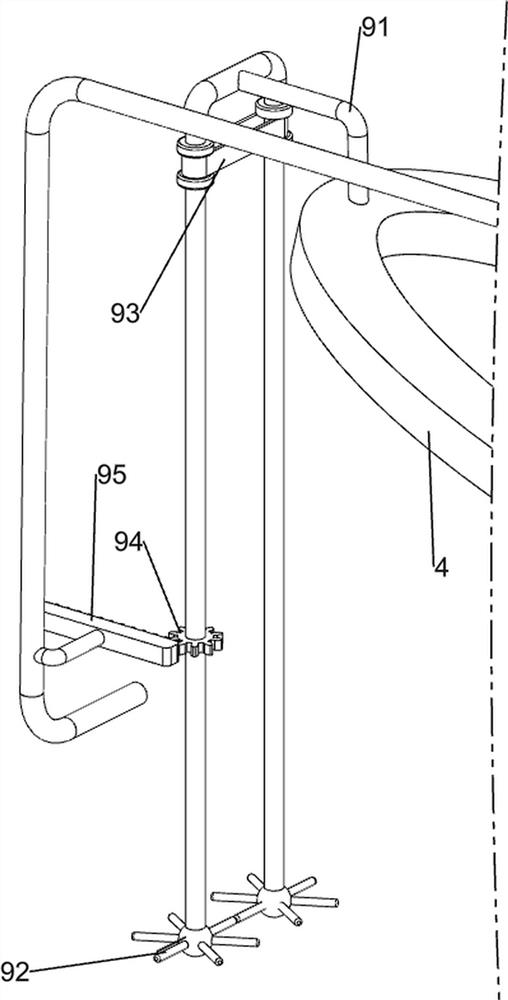

[0075] On the basis of Example 2, such as Figure 4-Figure 8 As shown, it also includes a gravity rotation mechanism 7, and the gravity rotation mechanism 7 includes a third support rod 71, a rotation rod 72 and a water receiving bucket 73, and the base 1 is provided with a third support rod 71 in the middle of the front and rear sides. Rotation is provided with rotation bar 72 between the 3rd support bar 71, and rotation bar 72 contacts with water tank 62, and rotation bar 72 left tops are provided with receiving bucket 73.

[0076] When the water in the water tank 62 flows into the water receiving bucket 73, the water receiving bucket 73 is toppled downward due to the amount of water in the water receiving bucket 73 reaching a certain level, thereby driving the left side of the rotating rod 72 to swing downward and the rotating rod 72 to the right. Swing upwards sideways, and then make the water in the water receiving bucket 73 flow into the water tank 3, after the water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com